Plastic extruder with good safety

A plastic extruder and safety technology, applied in the field of plastic extruders, can solve the problems of artificial heating, easy spilling of plastic particles, hidden safety hazards, etc., and achieve the effects of increasing the movement speed, increasing the falling efficiency, and increasing the vibration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

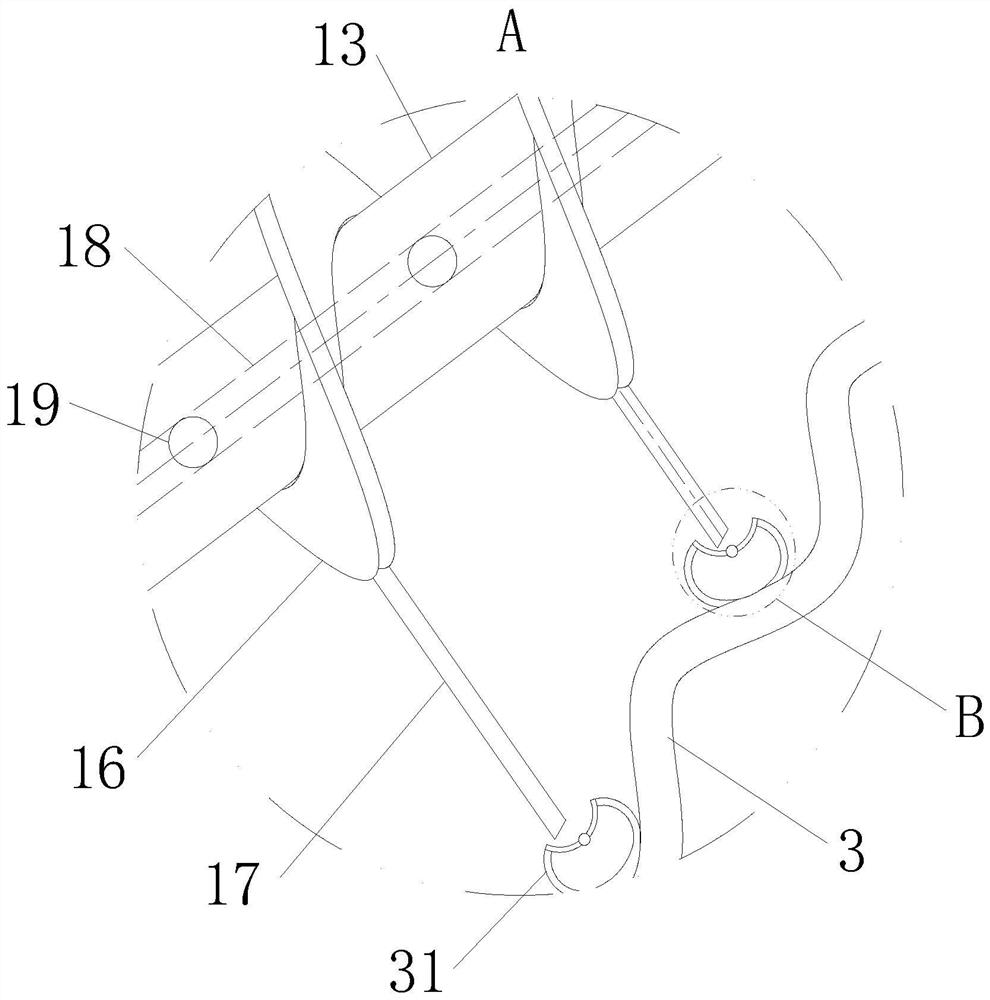

[0029] As an embodiment of the present invention, a group of swing rods 17 are evenly distributed on the outer periphery of the auger blades 16, and the length of the swing rods 17 gradually increases from the bevel gear 14 to the direction of the inner wall of the feed hopper 12, and the swing rods 17 are in the shape of a pine cone. Arranged on the outer periphery of the auger blade 16; there is a No. 1 hole 18 in the rotating shaft 13, and the No. 1 hole 18 communicates with the hot air blower through a pipeline; 19. Through the guidance of No. 1 hole 18 and No. 2 hole 19, the hot air is stretched into the inside of the feed hopper 12, so that the hot air is continuously emitted from the inside of the plastic particles in the feed hopper 12 to the outside, further increasing the flow of hot air in the plastic. The uniform and rapid diffusion in the gap between the particles, and the pine cone-shaped swing rod 17 further increases the gap between the plastic particles near th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com