Tobacco shred real-time monitoring method and device based on elbow dilute phase conveying high-speed imaging

A high-speed imaging, dilute phase conveying technology, applied in conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of incomplete sampling, inability to use tobacco for real-time monitoring, low efficiency, etc., to achieve good real-time performance, easy to collect Image, the effect of capturing images quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In order to enable those skilled in the art to better understand the cut tobacco size detection method and device provided by the present invention, the technical solutions in the present invention will be clearly and completely described below in conjunction with the following examples. Obviously, the described examples are only examples of the present invention. Some embodiments, but not all embodiments of the present invention.

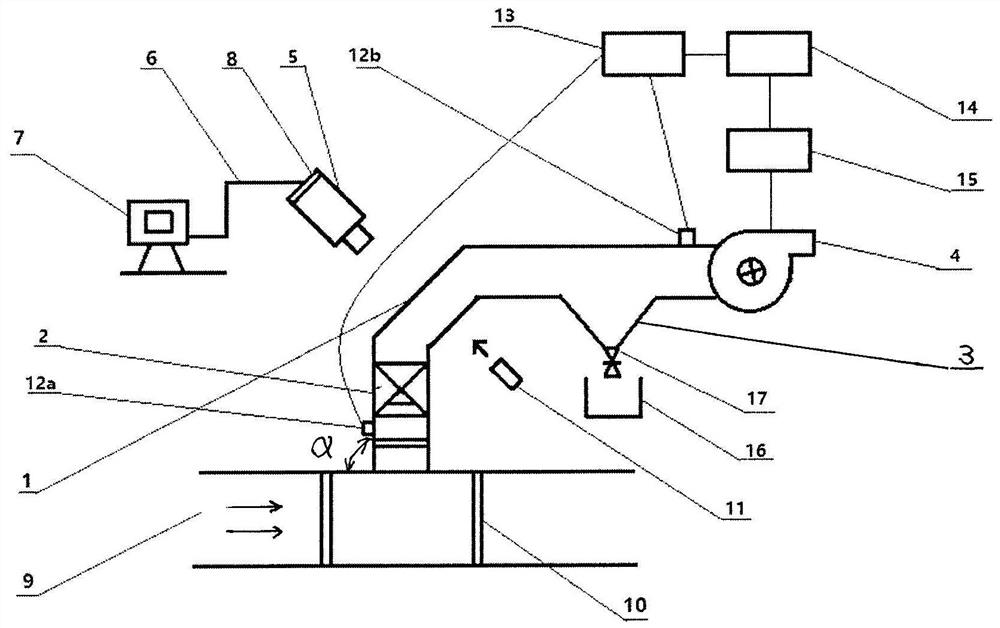

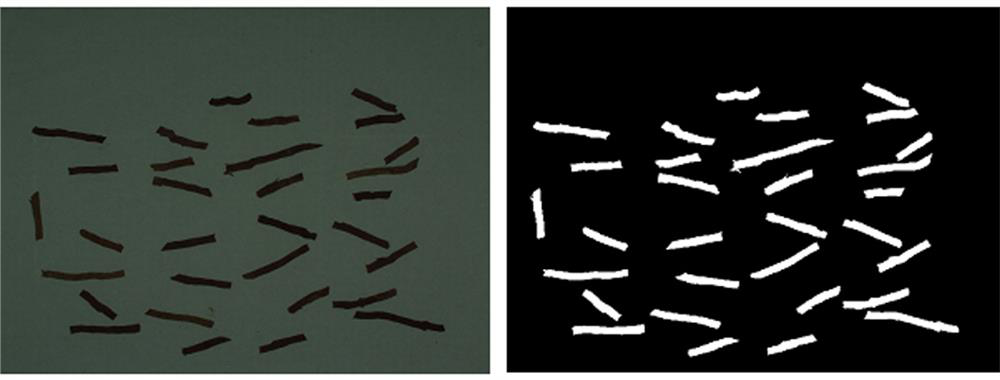

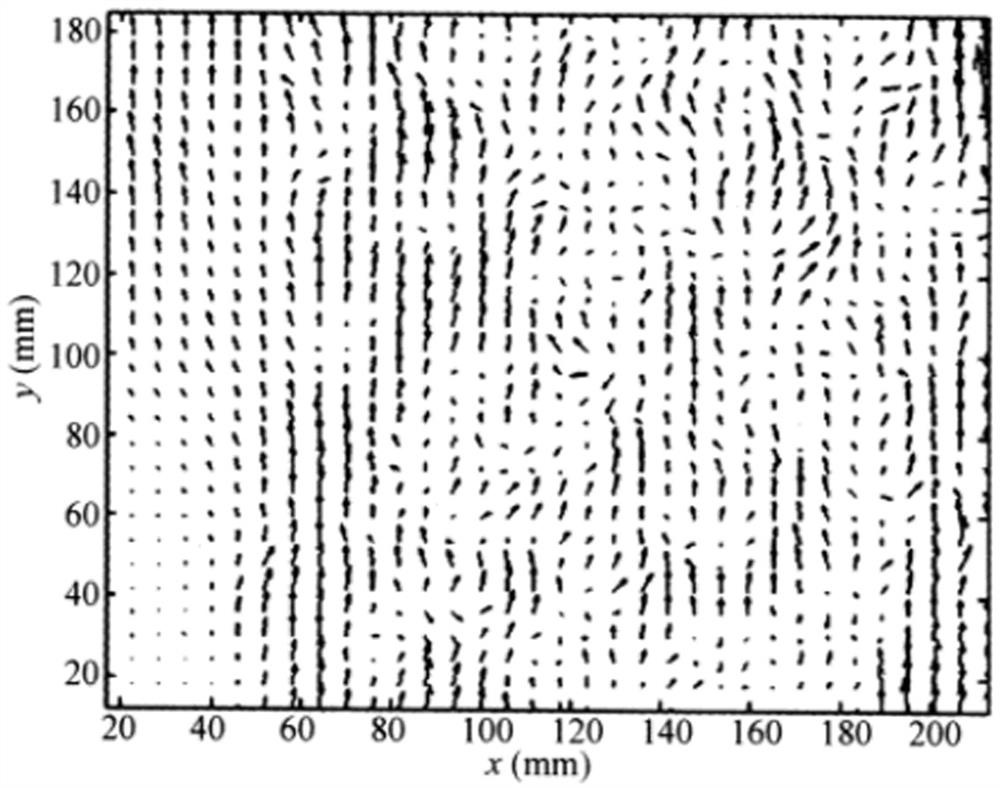

[0060] Turn on the supplementary light source of the high-speed camera system, set the acquisition frequency of the high-speed camera 5 and the image acquisition and analysis program to 30min / time, and the single sampling time to 20s, and set the working cycle of the PLC control system to be the same as the camera image acquisition frequency. According to the apparatus and method described above, a continuous distribution of the size of the cut tobacco and a distribution of the speed of the cut tobacco is obtained. The continuous distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com