Steering device special for wind power tower drum

A steering device, wind power tower technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of damage to the outer wall paint of the tower, easy rust of the tower, etc., to avoid paint damage, convenient production, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

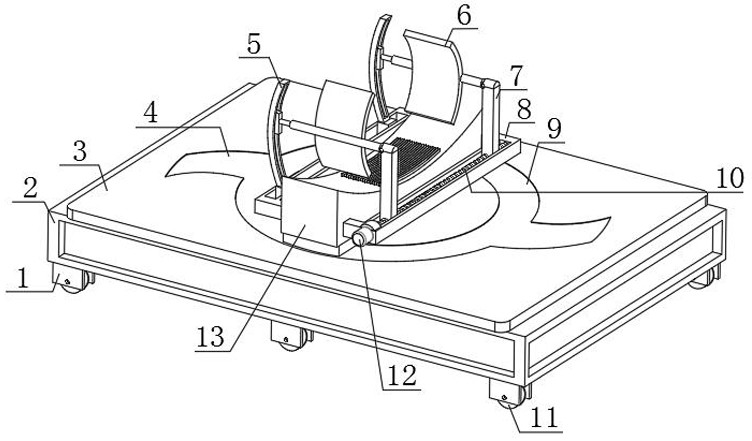

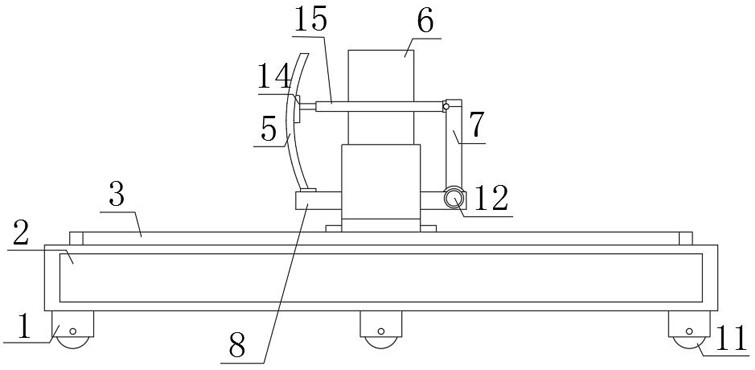

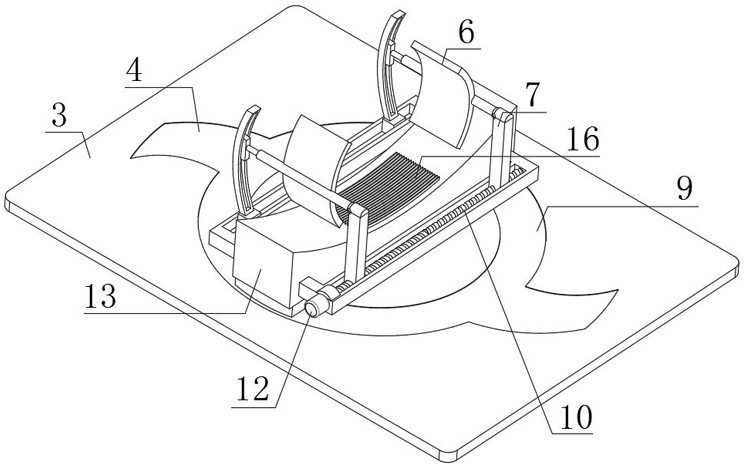

[0029] refer to Figure 1-5 , a special steering device for wind power towers, comprising a main body frame 2, a steering platform 3 is fixedly connected to the top outer wall of the main body frame 2, a mounting pad 17 is fixedly connected to the central position of the top outer wall of the steering platform 3, and the top outer wall of the mounting pad 17 A rotating shaft is provided at the central position, and a lower anti-wear copper sheet 18 and an upper anti-wear copper sheet 19 are sleeved on the outer wall of the rotating shaft. A sleeve 20 is sleeved on the outer wall of the rotating shaft, and plugs are provided on the outer walls of both sides of the sleeve 20. 23. The top of the casing 20 is fixedly connected to the saddle support 13, the lower anti-wear copper sheet 18 is fixedly connected to the mounting pad 17, and the upper anti-wear copper sheet 19 is fixedly connected to the top outer wall of the saddle support 13, and the saddle support Both sides outer wa...

Embodiment 2

[0040] refer to Figure 6 , a special steering device for wind power towers, comprising a main body frame 2, a steering platform 3 is fixedly connected to the top outer wall of the main body frame 2, a mounting pad 17 is fixedly connected to the central position of the top outer wall of the steering platform 3, and the top outer wall of the mounting pad 17 A rotating shaft is provided at the central position, and a lower anti-wear copper sheet 18 and an upper anti-wear copper sheet 19 are sleeved on the outer wall of the rotating shaft. A sleeve 20 is sleeved on the outer wall of the rotating shaft, and plugs are provided on the outer walls of both sides of the sleeve 20. 23. The top of the casing 20 is fixedly connected to the saddle support 13, the lower anti-wear copper sheet 18 is fixedly connected to the mounting pad 17, and the upper anti-wear copper sheet 19 is fixedly connected to the top outer wall of the saddle support 13, and the saddle support Both sides outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com