Starch preparation system for papermaking

A preparation system and technology for starch, applied in the field of papermaking, can solve problems such as unavailability, uncontrollable pH value, lower starch utilization efficiency, etc., and achieve the effects of improving product quality, reducing the generation of peculiar smell of paper, and reducing acidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

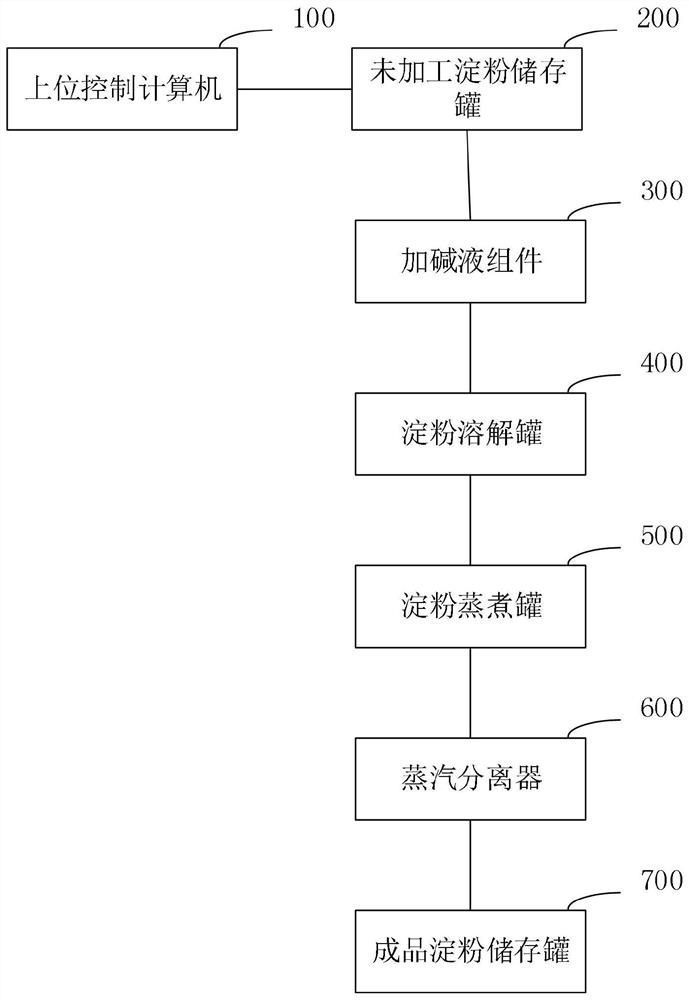

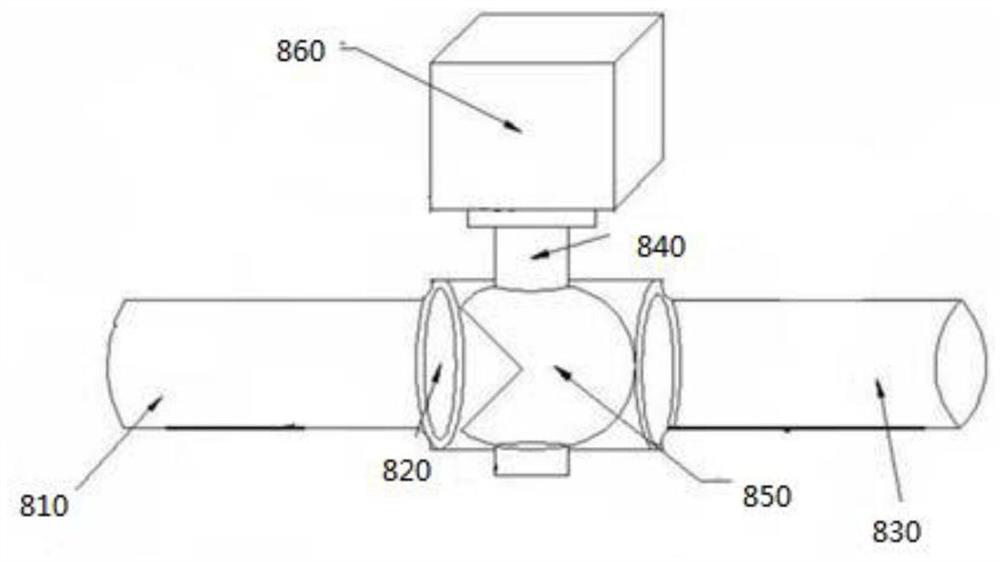

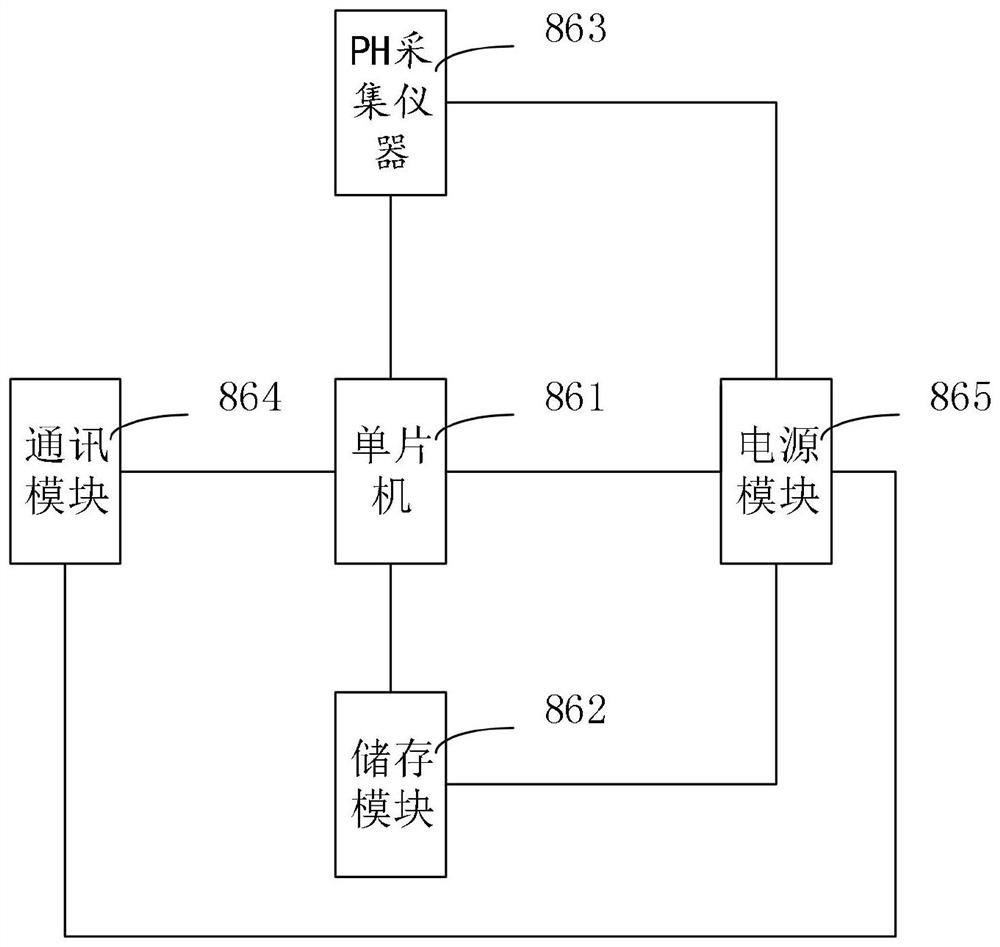

[0023] refer to Figure 1 to Figure 4 , a starch preparation system for papermaking, comprising: a host control computer 100, an unprocessed starch storage tank 200, an lye adding assembly 300, a starch dissolving tank 400 and a starch cooking tank 500; the unprocessed starch storage tank 200 and the The starch dissolving tank 400 is connected by the first starch delivery pipe 110, and the first starch delivery pipe is provided with a first control valve 111; the starch dissolving tank 400 and the starch cooking tank 500 are connected by the second starch delivery pipe 120 , the second starch delivery pipe 120 is provided with a second control valve 800, and the second control val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com