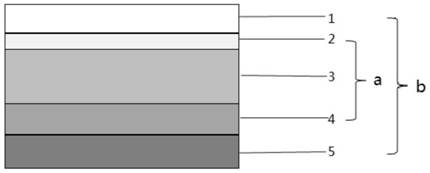

Infinitely hot-bendable polyester protective film as well as preparation method and application thereof

A technology of protective film and polyester base film, which is applied in the direction of film/sheet-shaped adhesives and adhesives, which can solve the problems that the PET protective film cannot fully fit the edge of the 3D curved surface and is easy to warp, and achieve coating The cloth process is easy to control, good resistance to nail embossing, and the effect of less process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

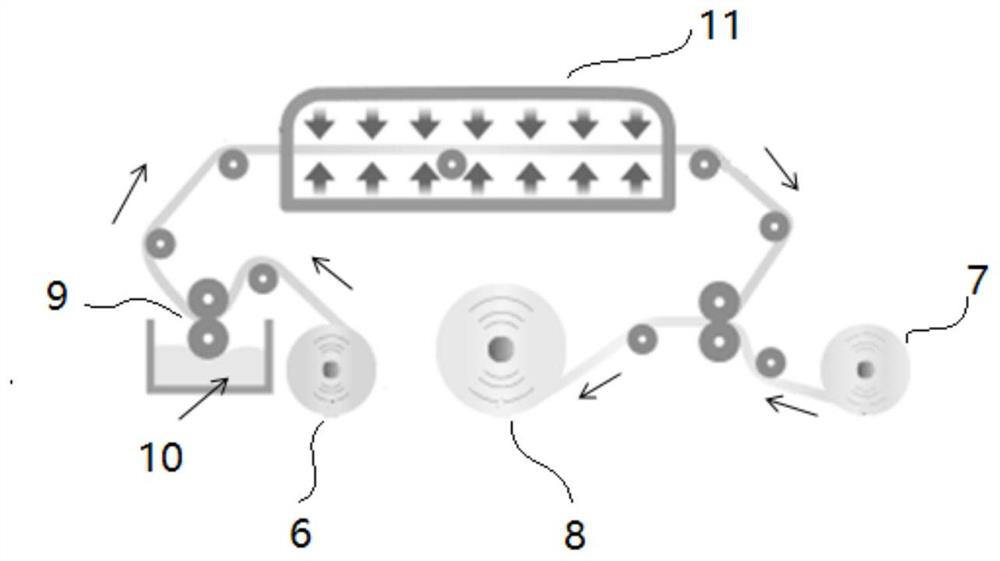

Method used

Image

Examples

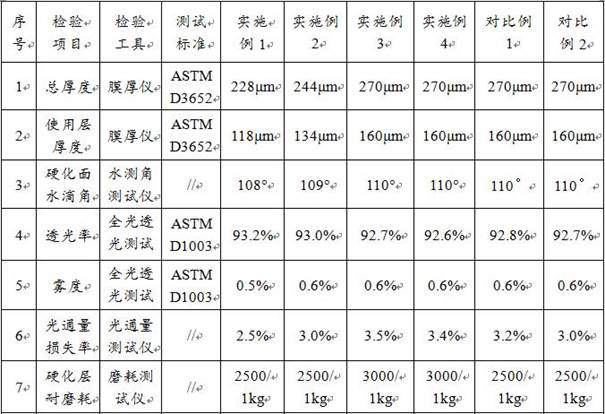

Embodiment 1

[0073] First of all, the first step is to prepare the semi-finished polyester base film. The specific operation is: place the silicone oil release film on the first roll, and the release surface is sent to the coating head as the coating surface, with a thickness of 50 μm and a release force of 3gf; the second roll is placed in the low-viscosity silicone process. The film is used as process protection, with a thickness of 60 μm, and the viscosity of the silica gel is preferably 4 gf. The polyester solution formulation includes 25 parts of high Tg saturated polyester resin particles, 10 parts of medium Tg saturated polyester resin particles, 5 parts of low Tg saturated polyester resin particles, 8 parts of curing agent, 0.5 parts of leveling aid, 0.3 parts of UV absorber agent, 80 parts of ethyl acetate, 5 parts of cyclohexanone; the solid content of the solution is 33.7%, and the viscosity is 350cps / 25℃. The prepared polyester solution is pumped into the cavity of the slit coa...

Embodiment 2

[0077] Manufactured as in Example 1 in a three-step process. The difference between formula and process parameters is: in step one, the polyester solution formula includes 30 parts of high Tg saturated polyester resin particles, 5 parts of medium Tg saturated polyester resin particles, 10 parts of low Tg saturated polyester resin particles, 10 parts of curing agent , 0.6 parts of leveling aids, 0.3 parts of UV absorbers, 80 parts of ethyl acetate, 8 parts of cyclohexanone; the solid content of the solution is 35.6%, the viscosity is 400cps / 25°C; the pump speed is 30rpm, and the line speed is 5m / min to obtain polyester The base film thickness was 100 μm. In the second step, the mesh number of the gravure roll is 100 meshes, the line speed is 10 m / min, and the thickness of the hardened layer is 4 μm. In the third process, high-viscosity acrylic pressure-sensitive adhesive is selected, the glue supply pump speed is 18pm, the coating line speed is 9m / min, and the pressure-sensiti...

Embodiment 3

[0079] Manufactured as in Example 1 in a three-step process. The difference between formula and process parameters is: in step one, the polyester solution formula includes 30 parts of high Tg saturated polyester resin particles, 10 parts of medium Tg saturated polyester resin particles, 5 parts of low Tg saturated polyester resin particles, and 11 parts of curing agent , 0.6 parts of leveling aids, 0.3 parts of UV absorbers, 80 parts of ethyl acetate, 6 parts of cyclohexanone; the solid content of the solution is 33.9%, the viscosity is 490cps / 25°C; the pump speed is 28rpm, and the line speed is 3m / min to obtain polyester The base film thickness was 120 μm. In the second step, the mesh number of the gravure roll is 80 meshes, the line speed is 9 m / min, and the thickness of the hardened layer is 5 μm. In the third process, a high-viscosity silicone pressure-sensitive adhesive is selected, the glue supply pump speed is 21 pm, the coating line speed is 8 m / min, and the pressure-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tackiness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com