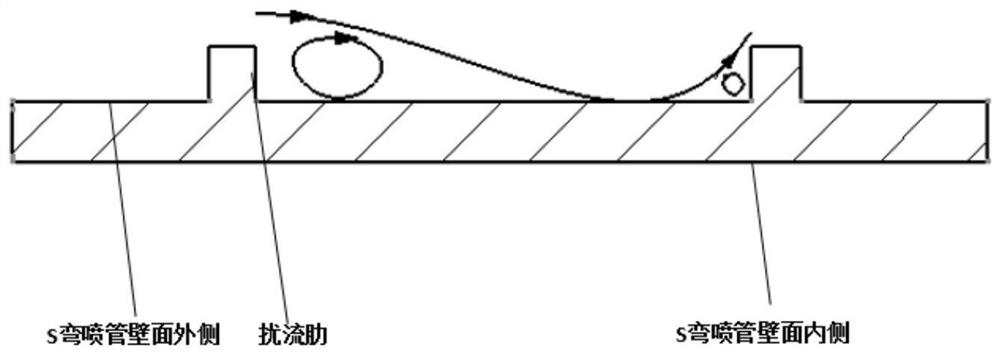

Three-duct S-shaped spray pipe with turbulent flow rib-air film cooling structure

A film cooling and spoiler rib technology, applied in jet propulsion devices, machines/engines, etc., can solve the problem of damage, deformation, flow control of three-channel S-bend nozzles, large thermal stress of three-channel S-bend nozzles, etc. problem, to prevent deformation and strengthen the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

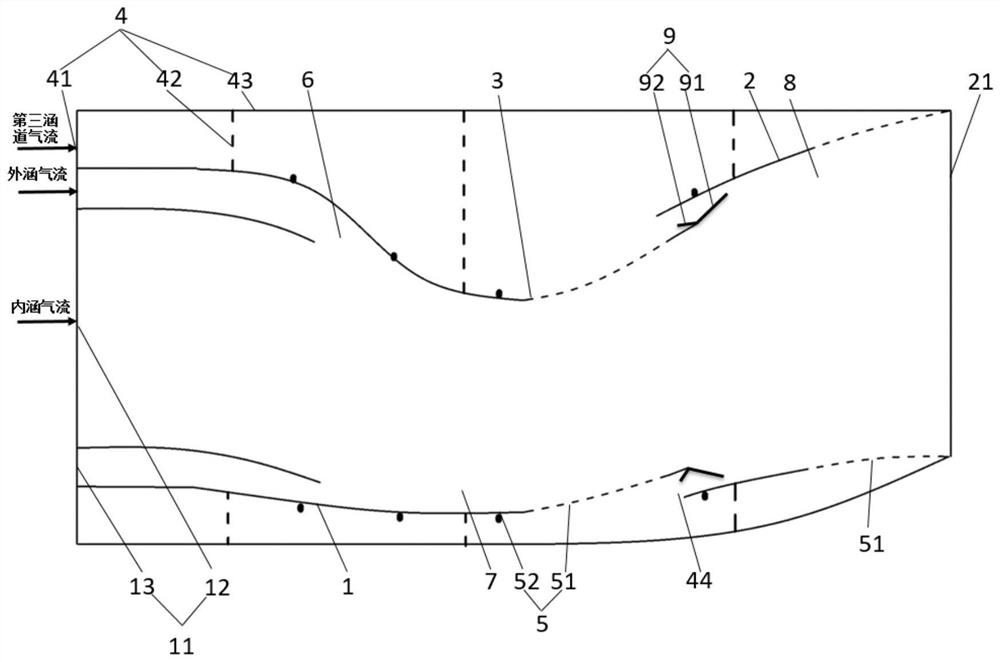

[0027] The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0028] refer to figure 2 As shown, a three-duct S-curved nozzle with a spoiler rib-film cooling structure of the present invention includes a convergent section 1, an expansion section 2, a third duct structure 4, and a spoiler rib-film cooling structure 5 And flow path adjusting device 9, the entrance of converging section 1 is the air inlet 11 of nozzle, and this air inlet 11 is made up of engine connotation air inlet 12 and outer culvert air inlet 13, and the outlet of expansion section 2 is nozzle The exhaust port 21. The outlet of the converging section 1 is connected to the inlet of the diverging section 2, where a nozzle throat 3 is formed.

[0029] The third duct structure 4 includes a third duct inlet 41 , a third duct support plate 42 , a third duct outer wall 43 and a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com