Conduction oil circulation fault diagnosis system

A fault diagnosis system and fault diagnosis technology, which are applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of the steam-conducting oil dual-medium boiler system adaptability to be verified, and the inability to monitor the boiler system. , to reduce the risk of overfitting, improve monitoring efficiency, prediction accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

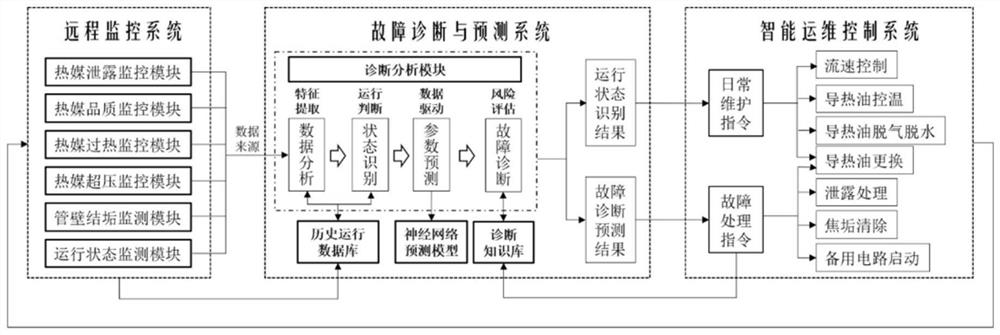

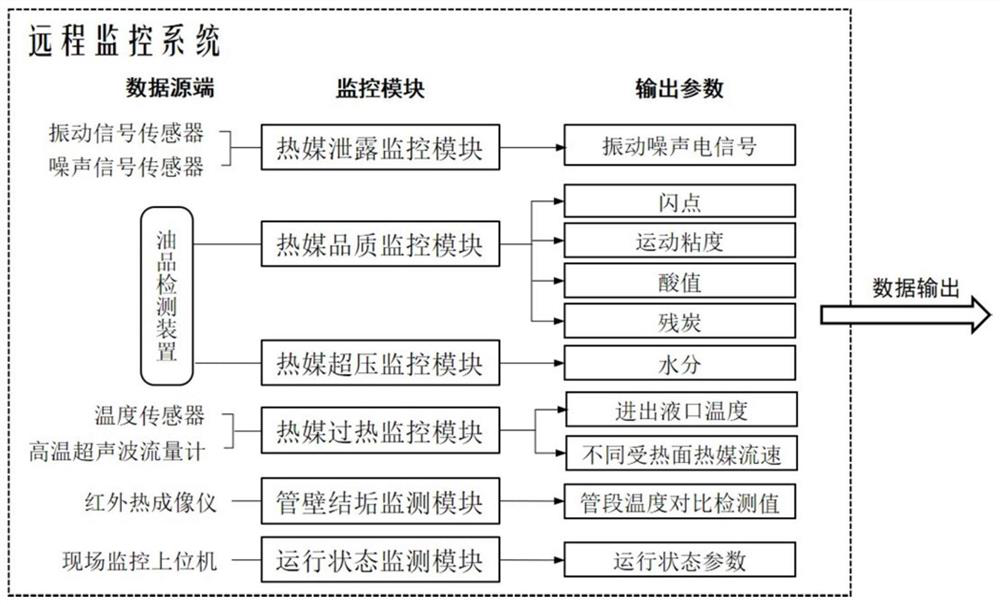

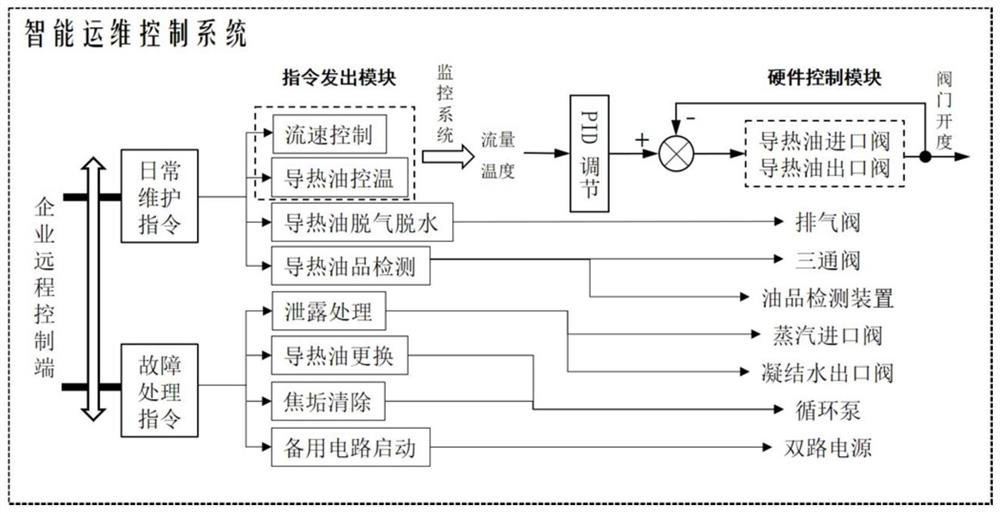

[0033] In a preferred embodiment of the present invention, a heat transfer oil circulation fault diagnosis system is provided, which is used for diagnosing the heat transfer oil cycle fault of a steam-heat transfer oil dual-medium boiler. The steam-heat transfer oil dual-media boiler is A boiler type that adds a heat transfer oil heat exchange circuit to a traditional steam cycle system. The diagnostic system sets up monitoring modules including multiple failure modes including heat transfer oil leakage, heat transfer oil deterioration, heat transfer oil overtemperature and overpressure, pipe wall fouling, etc. Carry out identification and division, realize fault prediction according to different states, and realize daily maintenance and fault handling of the system. Specifically, as figure 1 As shown, the functional modules of the diagnostic system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com