Double-temperature refrigerating system and refrigerating device

A refrigeration system and refrigeration device technology, which is applied to household refrigeration devices, refrigerators, refrigeration components, etc., and can solve the problems that the double evaporators cannot independently control the refrigeration cycle, cannot effectively control temperature fluctuations, and have complex structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

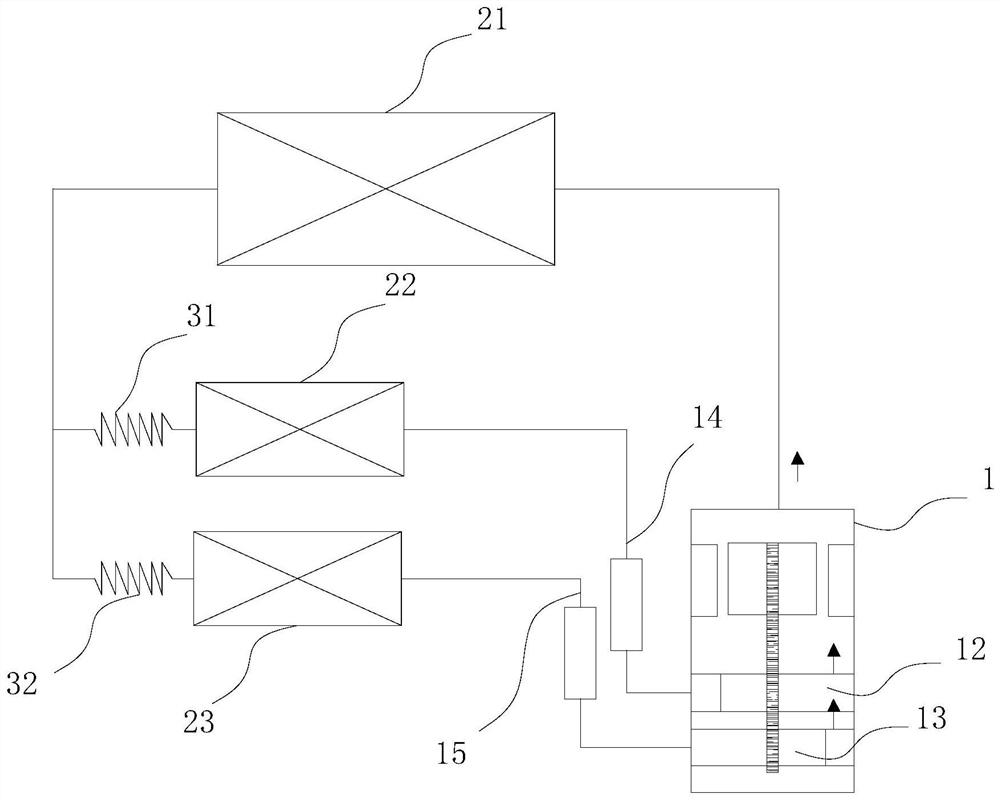

[0042] Such as figure 1As shown, the dual-temperature refrigeration system includes: a compressor 1 , a condenser 21 , a first evaporator 22 , a second evaporator 23 , a first throttling device 31 and a second throttling device 32 .

[0043] The compressor 1 is used for compressing refrigerant. The compressor 1 includes a first compression chamber 12 on the upper part and a second compression chamber 13 on the lower part. Both the first compression chamber 12 and the second compression chamber 13 are variable volume compression chambers. A discharge port is provided on the top of the compressor 1 , a first suction port 14 is provided on the first compression chamber 12 , and a second suction port 15 is provided on the second compression chamber 13 .

[0044] One end of the condenser 21 is connected to the exhaust port of the compressor 1, and the other end is respectively connected to the first evaporator 22 and the second evaporator 23, and the first evaporator 22 and the sec...

Embodiment 2

[0050] Such as figure 2 As shown, the difference between the dual-temperature refrigeration system in this embodiment and the dual-temperature refrigeration system in Embodiment 1 is that the dual-temperature refrigeration system also includes a first on-off valve 41 and an intermediate on-off valve 43, and the first on-off valve 41 Set between the first evaporator 22 and the first suction port 14, one end of the intermediate on-off valve 43 is connected between the first on-off valve 41 and the first suction port 14, and the other end of the intermediate on-off valve 43 It is connected between the second evaporator 23 and the second suction port 15 . The remaining parts are the same as the dual-temperature refrigeration system in Embodiment 1, and will not be repeated here.

[0051] In this embodiment, the dual-temperature refrigeration system has two working modes:

[0052] First, when both the first evaporator 22 and the second evaporator 23 need refrigeration, the first...

Embodiment 3

[0056] Such as image 3 As shown, the difference between the dual-temperature refrigeration system in this embodiment and the dual-temperature refrigeration system in Embodiment 1 is that the dual-temperature refrigeration system also includes a second on-off valve 42 and an intermediate on-off valve 43, and the second on-off valve 42 Located between the second evaporator 23 and the second suction port 15, one end of the intermediate on-off valve 43 is connected between the second on-off valve 42 and the second suction port 15, and the other end of the intermediate on-off valve 43 It is connected between the first evaporator 22 and the first suction port 14 . The remaining parts are the same as the dual-temperature refrigeration system in Embodiment 1, and will not be repeated here.

[0057] In this embodiment, the dual-temperature refrigeration system has two working modes:

[0058] First, when both the first evaporator 22 and the second evaporator 23 need refrigeration, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com