Fatigue fracture test device for hydraulic concrete

A hydraulic concrete, fatigue fracture technology, applied in measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve problems such as low efficiency, achieve stable pressure position, eliminate the influence of self-weight, ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

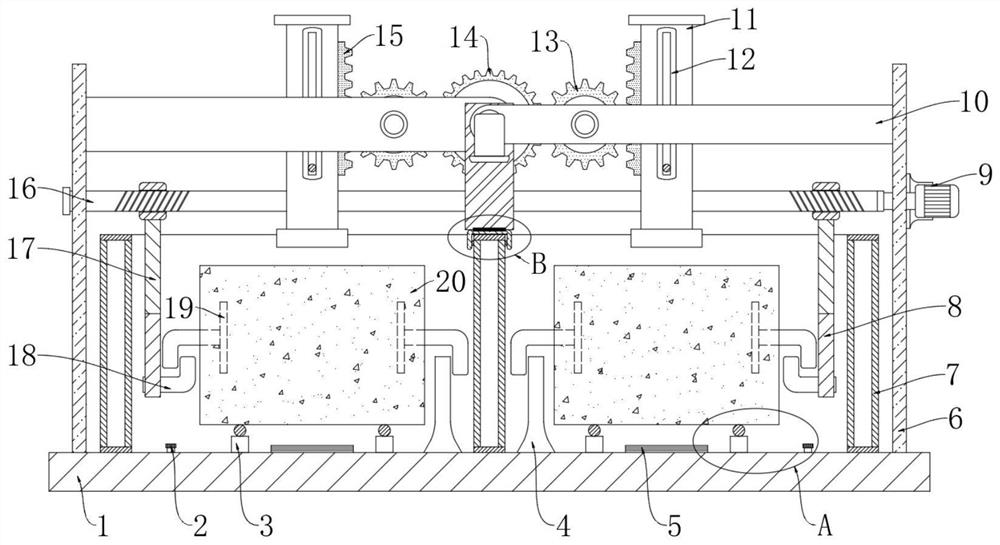

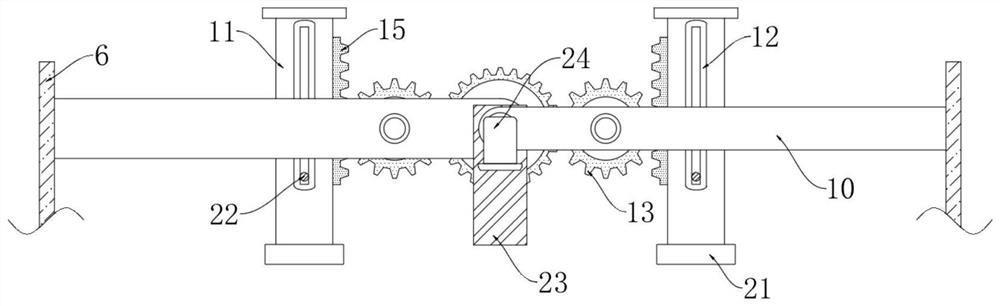

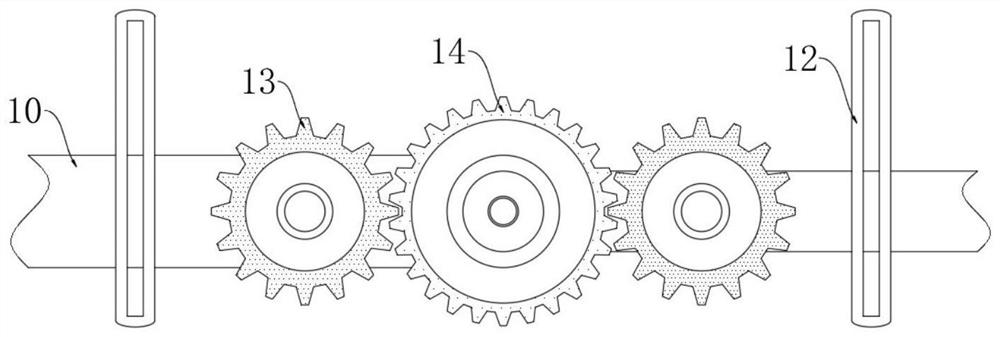

[0030] refer to Figure 1-7 , a hydraulic concrete fatigue fracture test device, comprising a test bench 1 and a plurality of concrete specimens 20, a plurality of hollow partitions 7 are fixedly installed on the test bench 1 through a sealing member 30, and a plurality of hollow partitions 7 jointly form a The test area and the control area, and the test area and the control area are symmetrical to each other, and the fatigue fracture test of the concrete is carried out in the test area and the control area at the same time, and the influence of various factors on the test results can be observed by using the control variable method. There are two support plates 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com