Top coal caving control method, system and device and electronic equipment

A technology of top coal caving and controller, applied in general control system, control/regulation system, program control and other directions, can solve the problems of low production efficiency and high cost, improve production efficiency, alleviate high cost and reduce labor cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

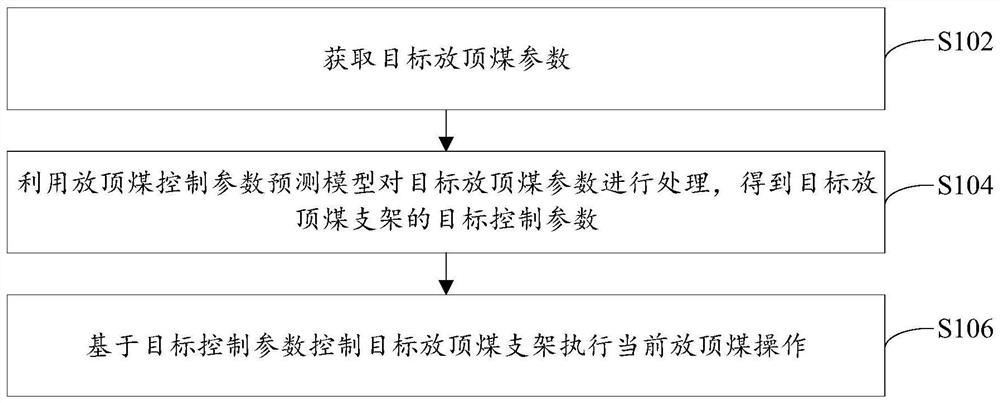

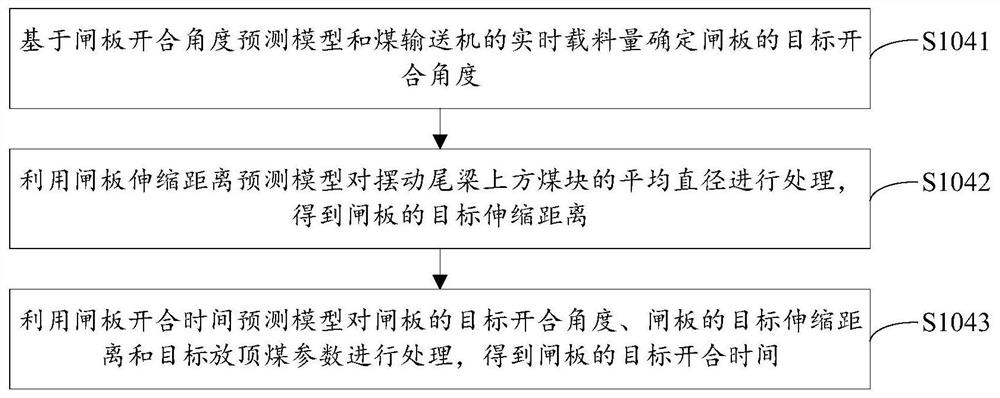

[0029] figure 1 A flow chart of a top coal caving control method provided by the embodiment of the present invention, such as figure 1 As shown, the method specifically includes the following steps:

[0030] Step S102, acquiring target top-coal caving parameters.

[0031] The top-coal caving control method provided by the embodiment of the present invention adopts the inventive idea of pre-prediction in order to save labor costs and avoid multiple starts and stops of equipment, and tries to complete the top-coal caving operation by accurately controlling the one-time start and stop of the gate. Specifically, in order to control the top-coal caving process, at the beginning of the implementation of the method, the target top-coal caving parameters must first be obtained, wherein the target top-coal caving parameters include: the thickness of the coal seam above the top beam of the target top-coal caving support, the target top-coal caving The average diameter of the coal bloc...

Embodiment 2

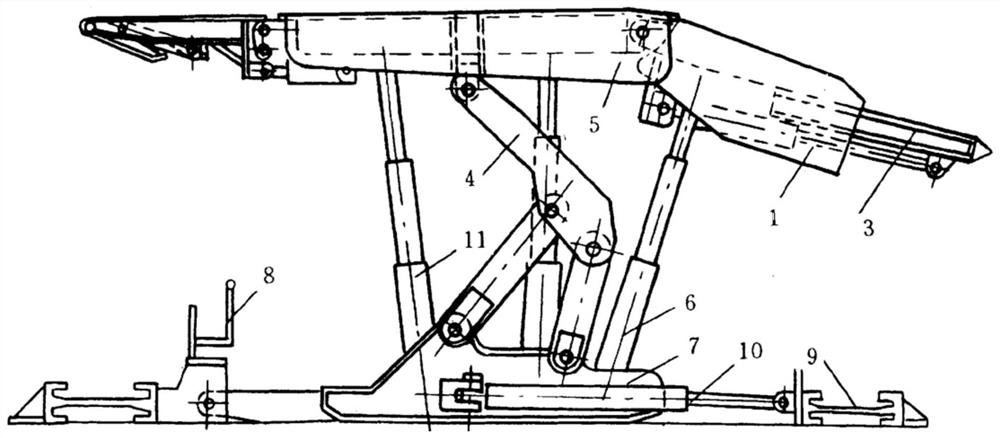

[0075] The embodiment of the present invention also provides a top coal caving control system, such as Figure 4 As shown, the top-coal caving control system includes: top-coal caving support, radar 12, structured light three-dimensional scanner 14, rangefinder 15, angle sensor 13, load measuring device 16 and top-coal caving controller (not shown in the figure). shown); the top-coal caving controller is mainly used to implement the top-coal caving control method provided in the first embodiment above, and the top-coal caving control system provided by the embodiment of the present invention will be specifically introduced below.

[0076] The radar is installed above the top beam of the top-coal caving support; the structured light 3D scanner is installed above the swing tail beam of the top-coal caving support; the rangefinder is installed at the first preset position of the swing tail beam; the angle sensor is installed on the top Junction of beam and swing tail boom.

[00...

Embodiment 3

[0085] The embodiment of the present invention also provides a top-coal caving control device, which is mainly used to implement the top-coal caving control method provided in the first embodiment above. Make a specific introduction.

[0086] Figure 5 It is a functional block diagram of a top coal caving control device provided by an embodiment of the present invention, as shown in Figure 5 As shown, the device mainly includes: a first acquisition module 100, a processing module 200, and a control module 300, wherein:

[0087] The first acquisition module 100 is used to obtain the target top-coal caving parameters; wherein, the target top-coal caving parameters include: the thickness of the coal seam above the top beam of the target top-coal caving support, the thickness of the coal block above the swing tail beam of the target top-coal caving support Average diameter and real-time loading capacity of coal conveyors.

[0088] The processing module 200 is used to use the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com