Dimension inspection method for automatically matching target value

A size inspection and automatic matching technology, applied in the direction of geometric CAD, special data processing applications, etc., can solve the problems of automation degree impact, enterprise economic loss, product scrapping, etc., to solve product misjudgment, improve work mode, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

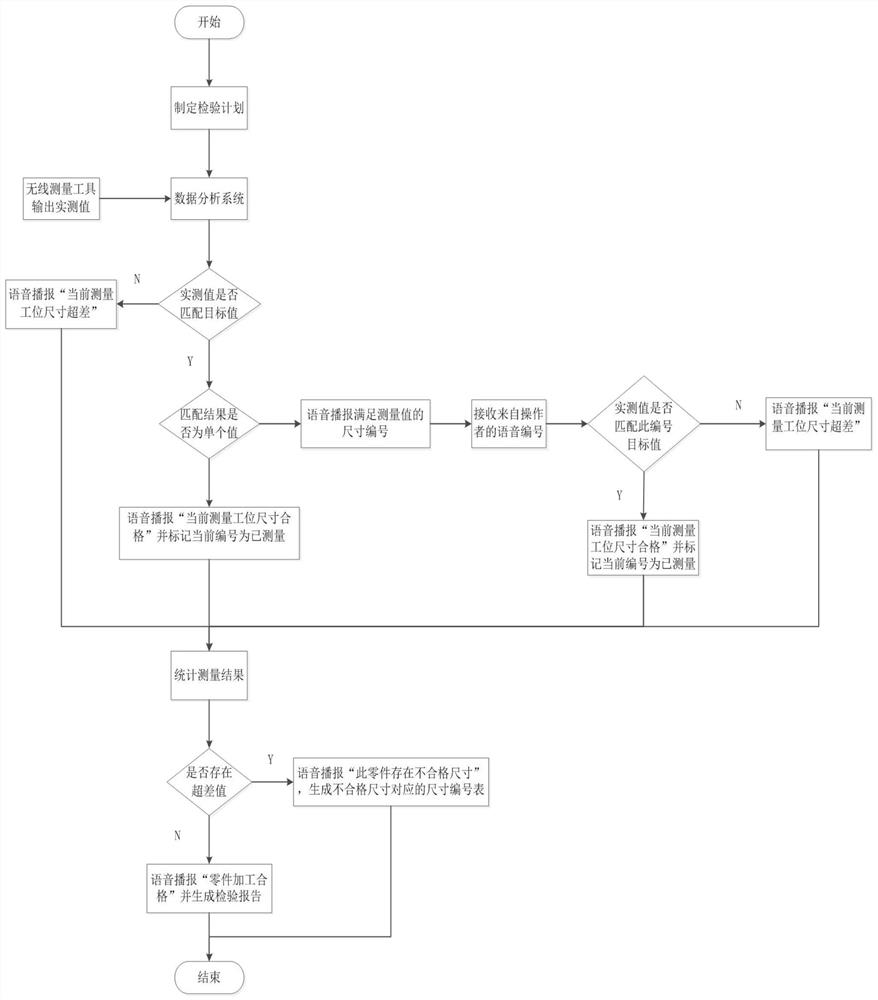

[0018] A dimension inspection method for automatically matching target values, comprising the following steps:

[0019] Step 1: Make a list of inspection plans and upload them to the database;

[0020] Step 2: According to the drawing number and version of the part, the data analysis system can automatically load the corresponding inspection plan;

[0021] Step 3: Part inspection, use the inspection tool with data transmission function to automatically transmit the measured value to the data analysis system;

[0022] Step 4: According to the received measured value, the data analysis system triggers the data analysis system to compare the measured value with each item of the inspection plan; verify whether the measured value is within the theoretical tolerance range of the target value;

[0023] Step 5: The data analysis system can match the measured value to the measured value column of the inspection item specified in the inspection plan list, and broadcast the measurement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com