Cylindrical battery

A cylindrical battery and cell technology, applied in the direction of cylindrical shell batteries/batteries, secondary batteries, battery pack components, etc., can solve the problems of limiting the use of cylindrical batteries, battery capacity and current limitations, and occupying internal space. To achieve the effect of ensuring quality, improving safety, and increasing battery capacity and current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

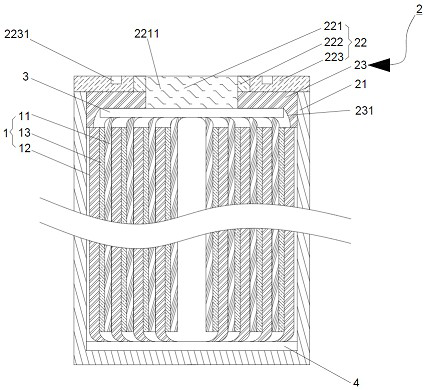

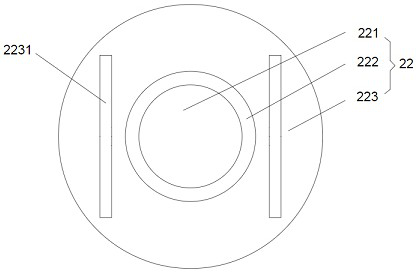

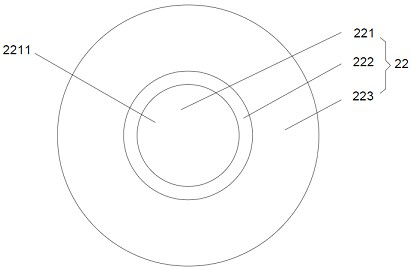

[0033] Figure 1 to Figure 4 It is the first embodiment of the present invention. A cylindrical battery includes a battery cell 1 , a casing assembly 2 wrapped outside the battery cell 1 , a first current collector 3 arranged on the top of the battery 1 , and a second current collector 4 arranged at the bottom of the battery 1 . The housing assembly 2 includes a bottom case 21 , a top cover 22 mounted on the bottom case 21 , and an insulating ring 23 disposed between the bottom case 21 and the top cover 22 , and the battery cell 1 is disposed in the bottom case 21 . The top cover 22 and the bottom case 21 are connected by welding. The first current collecting sheet 3 is in contact with the top cover 22 and separated from the bottom case 21 . The cell 1 includes a positive electrode sheet 11 , a negative electrode sheet 12 , and a separator 13 disposed between adjacent positive electrode sheets 11 and negative electrode sheets 12 . The positive electrode sheet 11 is electric...

Embodiment 2

[0043] Such as Figure 5 As shown, in this embodiment, the radial section of the protruding portion 2211 is a square, of course, other shapes such as polygons, circles, ellipses, irregular shapes, etc. can also be used in specific implementation. In this embodiment, the rest of the structures are the same as those in Embodiment 1, and redundant descriptions are omitted here.

[0044] First, in the present invention, since the positive electrode sheet is in direct contact with the first current collector, and the negative electrode sheet is in direct contact with the second current collector sheet, there is no need to set up an electrode sheet, which increases the volume of the positive electrode sheet and the negative electrode sheet, thereby increasing the battery capacity with current.

[0045] Second, the top cover is provided with an inner concave part, which can reduce the thickness of the top cover at the inner concave part, and when an explosion occurs, the impact forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com