Electric heating mat

A surface heater and electrode technology, applied in ohmic resistance heating, heating method, electric heating system, etc., can solve the problems of residual current flow and energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

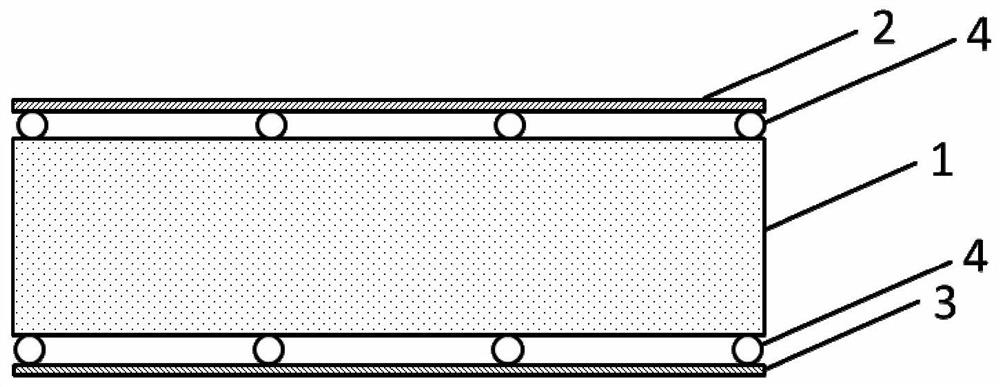

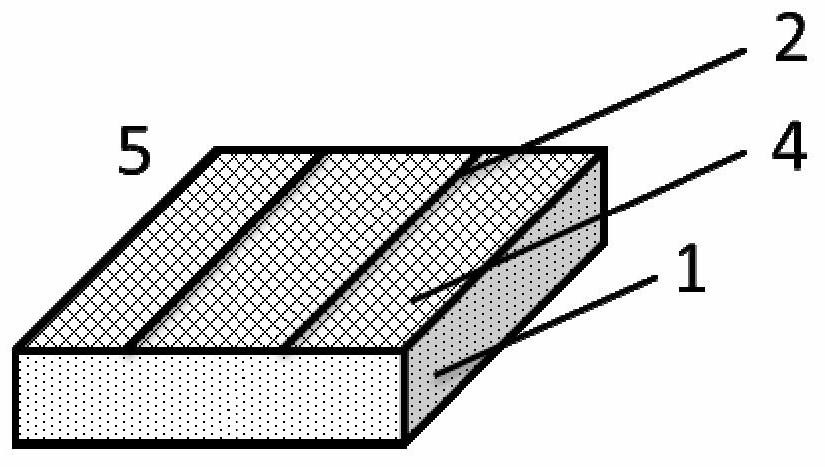

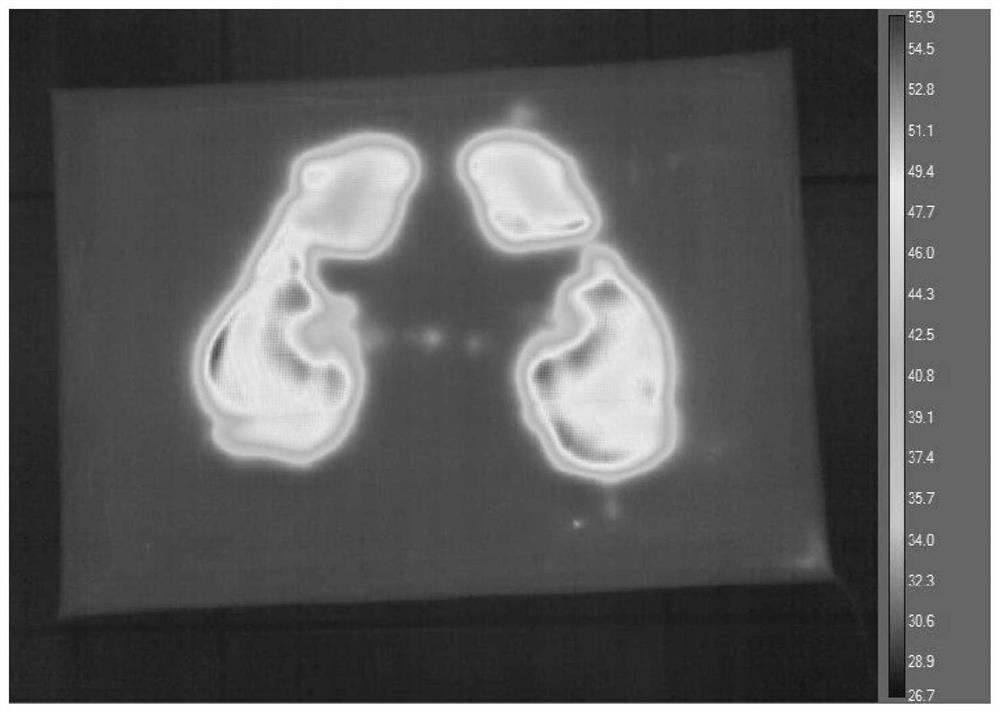

[0024] This example shows the working principle of the invention. Conductive PE foam (ELS-M) with dimensions 470x320 mm and thickness 6 mm is covered on both sides with mesh electrodes made of stainless steel. Mesh electrodes consisted of stainless steel wires with a mesh width of 1.4 mm and were loosely fixed to the foam at the edges. PET plastic filaments with a diameter of 0.5 mm and an interval of about 6 cm were woven into the wire mesh as a spacer between the lower mesh electrode and the conductive foam. 28 foam sheets (2 mm thick) were bonded approximately 8 cm apart from each other as spacers between the upper mesh electrode and the conductive foam. In principle, other materials and body shapes can also be used as spacers, as long as they do not prevent large-area contact between the electrodes and the conductive foam when loaded.

[0025] If a voltage of 60V is applied across the electrodes, no measurable current flows through the heating pad with no load (no load)....

example 2

[0029] This example shows the significance of spacers for reducing the no-load current in the no-load situation, whereby no spacers are used. Conductive foam with dimensions 21x21 cm and thickness 7 mm is covered with mesh electrodes made of stainless steel on both sides. Mesh electrodes consisted of stainless steel wires with a mesh width of 1.4 mm and were loosely fixed to the foam at the edges. There are no spacers. If a voltage of 60 V is applied to the electrodes, a small but easily measurable current (10 mA) flows through the heating pad without load, caused by random point contacts. If the pad is locally loaded, a higher current than in example 1 starts to flow at this location.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com