Plastic microsphere surface ozone treatment device

A technology of ozone treatment and microspheres, which is applied in the field of polymer microsphere preparation, can solve the problems of uneven surface modification and mutual adhesion of microspheres, and achieve the effects of avoiding mutual adhesion, simple and convenient operation, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

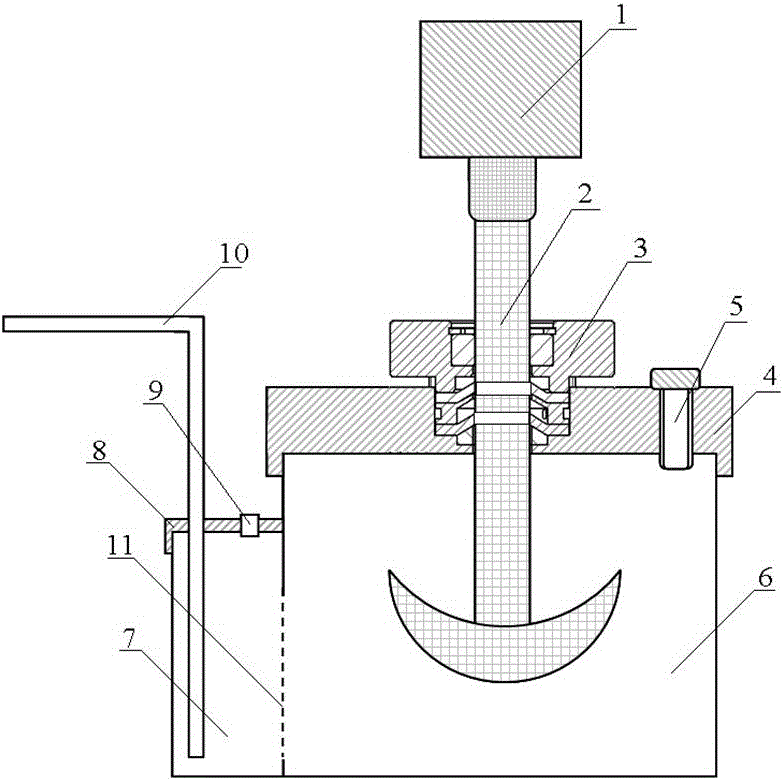

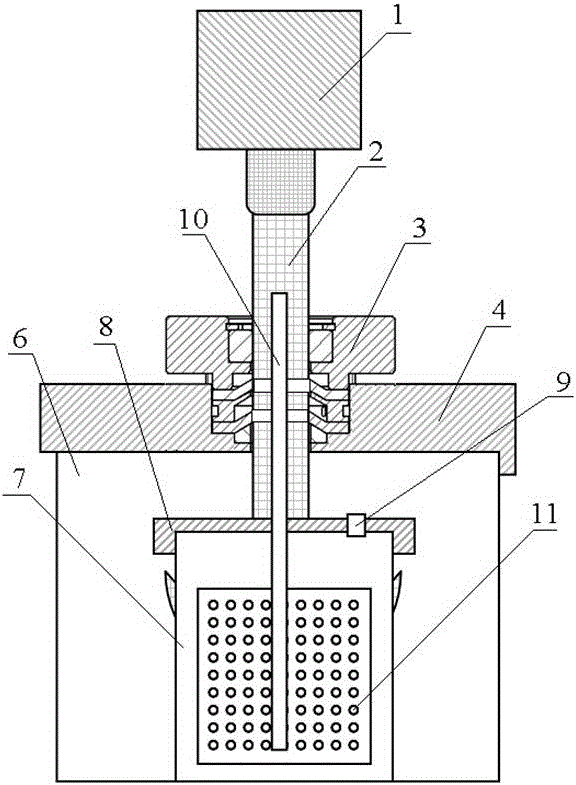

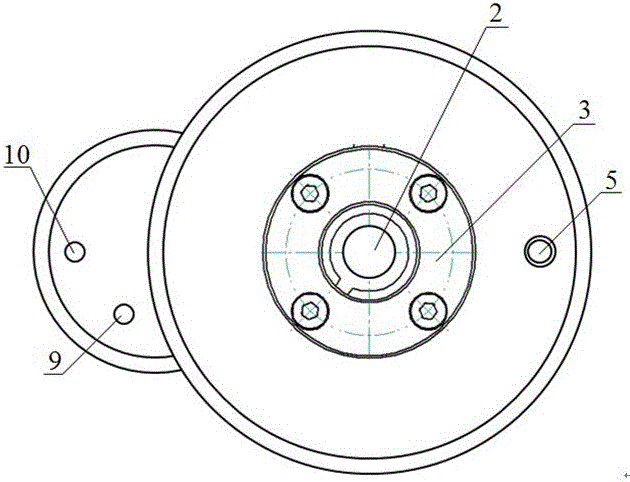

[0020] figure 1 It is the front view of the plastic microsphere surface ozone treatment device of the present invention, figure 2 It is a side view of the plastic microsphere surface ozone treatment device of the present invention, image 3 It is a top view of the device for ozone treatment on the surface of plastic microspheres of the present invention.

[0021] exist Figure 1~Figure 3 Among them, the plastic microsphere surface ozone treatment device of the present invention includes an electronic stirrer 1, a stirring rod 2, an anti-volatility component, a microsphere surface ozone treatment component and an ozone input pipe 10, and the anti-volatility component contains a dynamic sealing adapter 3 , sealing cover 4 and microsphere injection port 5, described microsphere surface ozone treatment assembly contains microsphere dispersion container 6, ozone dissolving tank 7, wall hole 11, cover 8 and liquid inlet 9, wherein, stirring bar 2 is provided with Stirring blade....

Embodiment 2

[0031] The structure of this embodiment is the same as that of Embodiment 1, except that the diameter of the wall hole 11 is one-fifth of the diameter of the plastic microsphere to be treated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com