A microchannel cold plate structure with reverse dredging function

A micro-channel and reverse technology, which is applied in the construction of electrical equipment components, cooling/ventilation/heating transformation, separation methods, etc., can solve problems such as restricting the development of airborne phased array radar cooling systems, micro-channel cold plate blockage, etc. , to achieve significant filtering effect, simple processing, and ensure the effect of working stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, the modes of the present invention include but are not limited to the following embodiments:

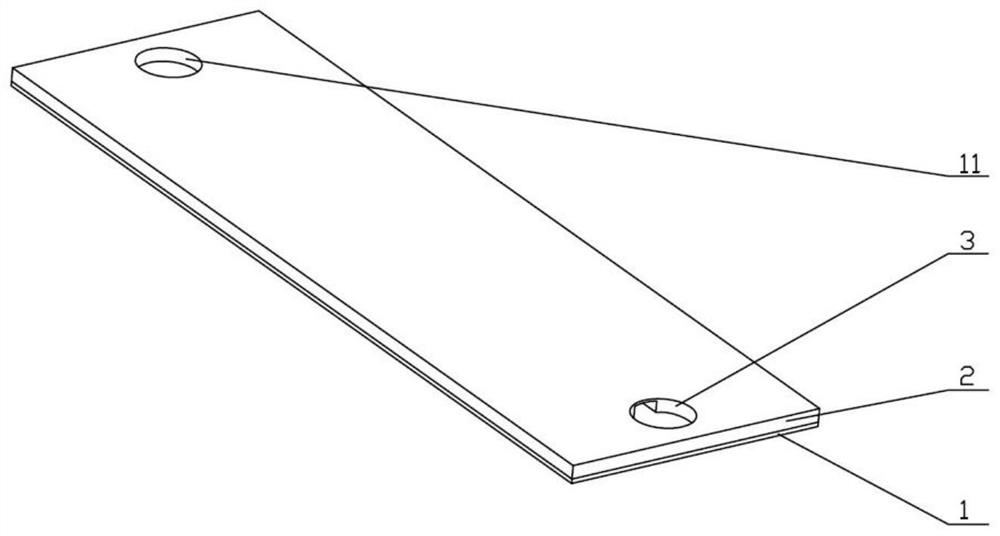

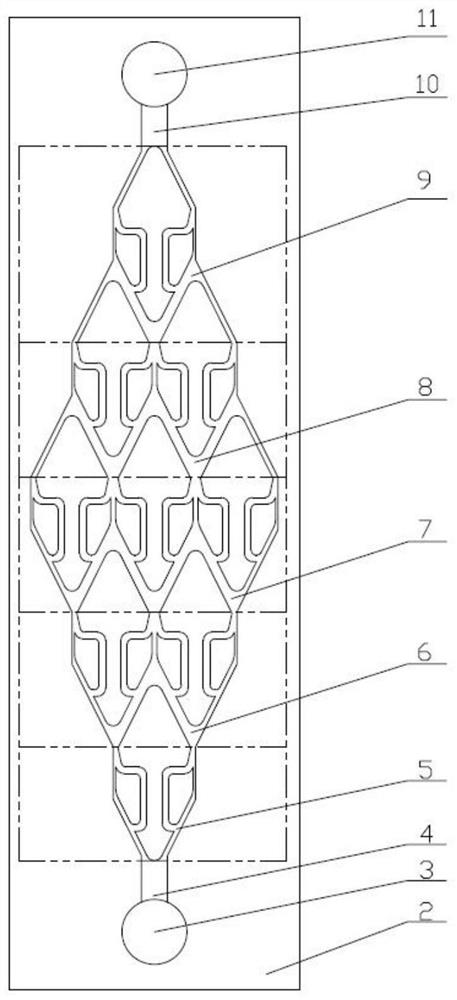

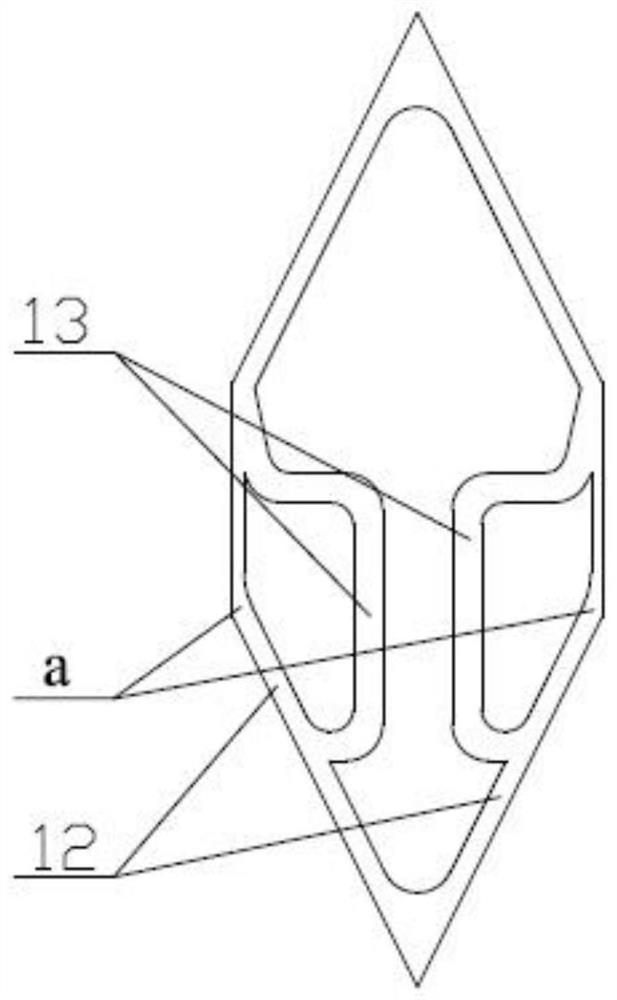

[0025] like Figure 1-Figure 7 As shown, a microchannel cold plate structure with reverse dredging function includes an upper cover plate 1 and a lower layer filter plate 2, the upper surface of the upper layer cover plate 1 is connected with a heat source, and the lower surface of the upper layer cover plate 1 is connected with the lower layer filter plate The upper surface of 2 is connected; the lower filter plate 2 is provided with a flow channel inlet 3 and a flow channel outlet 11, and the flow channel inlet 3 is connected with the inlet of the first-stage filter flow channel 5 through the filter plate main channel 4, and the first-stage filter flow channel 5 The outlet is connected to the inlet of the second-stage filter flow channel 6, the outlet of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com