Lithium battery producing and processing device

A processing device and lithium battery technology, applied in transportation and packaging, dissolving, mixing machines, etc., can solve the problem of single stirring method, and achieve the effect of increasing and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

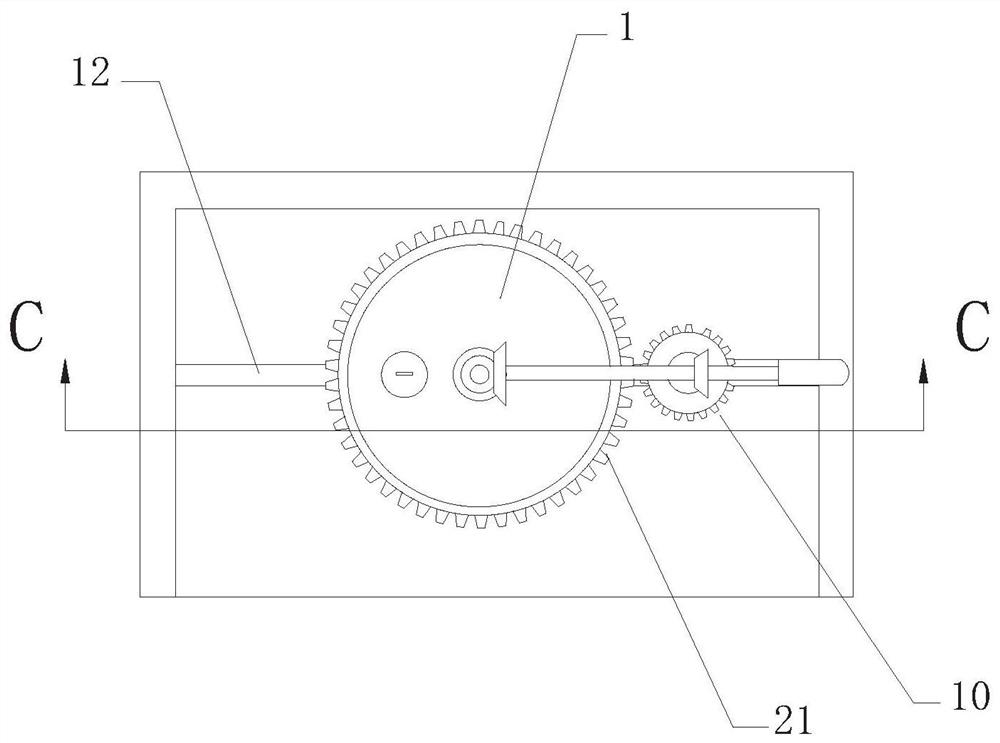

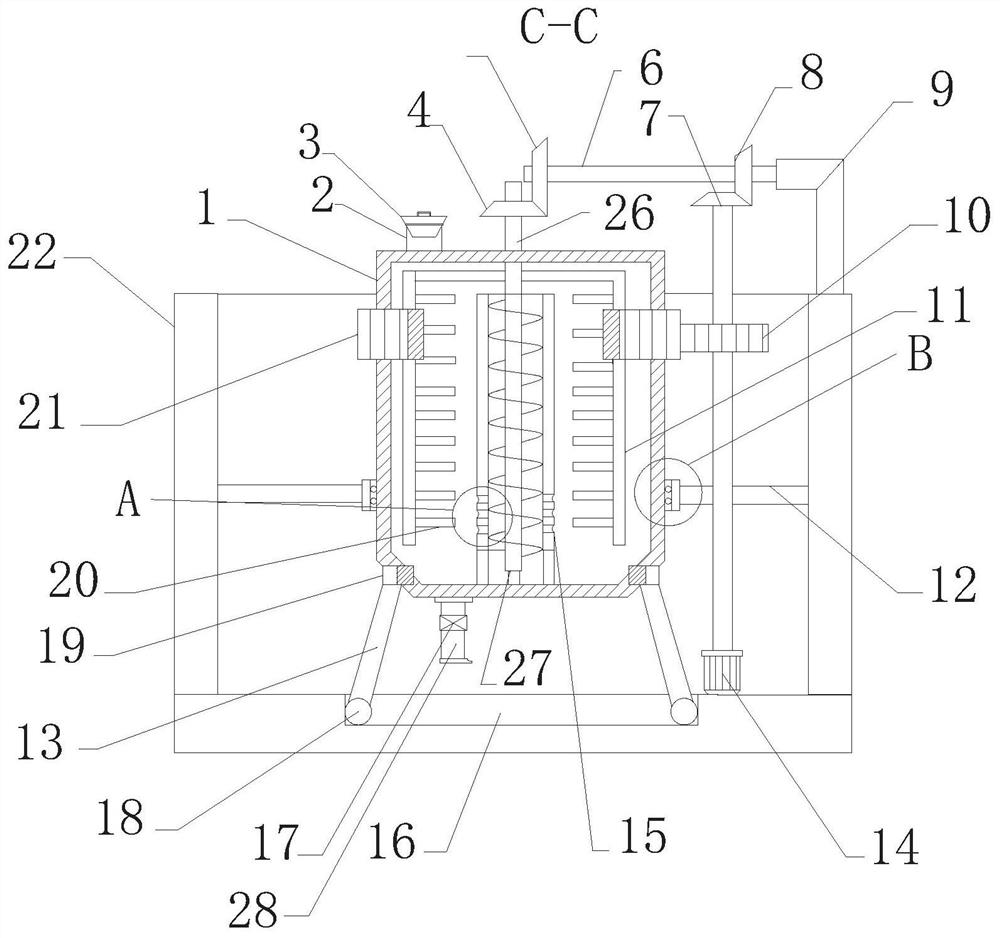

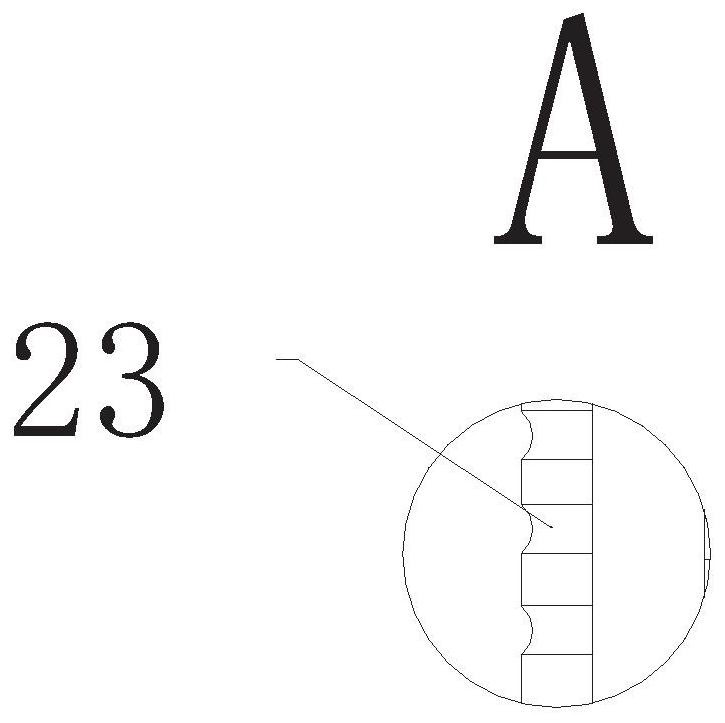

[0024] see Figure 1-4 , which is a schematic structural diagram of a lithium battery production and processing device in a preferred embodiment of the present invention. A lithium battery production and processing device in this embodiment includes a cylinder 1 and a lifting screw 26, and the outer wall of the cylinder 1 is provided with The gear ring 21, the gear ring 21 is meshed with a gear one 10, the gear one 10 is connected with the transmission shaft of the motor 14, the lifting screw 26 extends to the inside of the cylinder 1, and two sets of gears are arranged on the lifting screw 26 Stirring rods 11 The stirring rods 11 of the two groups are L-shaped, and several groups of secondary stirring rods 20 are arranged on the stirring rods 11 of the two groups. Located inside the built-in tube 15, the built-in tube 15 is connected to the bottom of the cylinder 1 through several sets of support columns, and several sets of through holes 23 are provided on the side wall of t...

Embodiment 2

[0028] see Figure 1-4 , a lithium battery production and processing device, on the basis of Example 1, the top of the cylinder 1 is provided with a feed port 2, the feed port 2 is provided with a closing plug 3, and the bottom of the cylinder 1 is provided with There is a group of supporting frames 19, and the supporting frames 19 are provided with several sets of supporting legs 13, and a group of rolling balls 18 are arranged on the bottom of the supporting legs 13, and the rolling balls 18 are rollingly connected to the circular ring provided on the floor of the outer box body 22. Inside the groove 16, there is also a group of fixed rings 25 on the outer side wall of the cylinder body 1. The inside of the fixed ring 25 is hollow, and two groups of balls 24 are connected in rotation in the inside, and the balls 24 are connected to the outer side wall of the cylinder body 1. Rolling contact, the fixed ring 25 is fixed on the inner side wall of the outer box 22 through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com