A method for controlling the elongation of hot-dip galvanizing four-roll skin pass mill

A control method and elongation rate technology, applied in the direction of elongation rate control, etc., can solve the problems of uncertain and frequent fluctuations in the control method, and achieve the effects of reducing length, optimizing PID parameters, and improving control speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

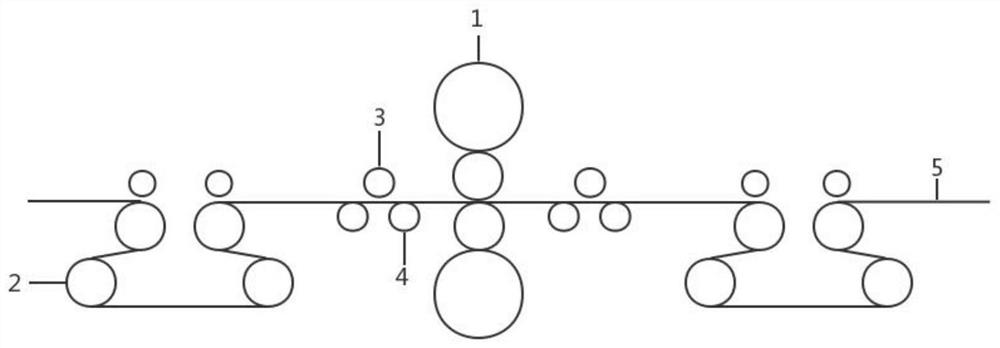

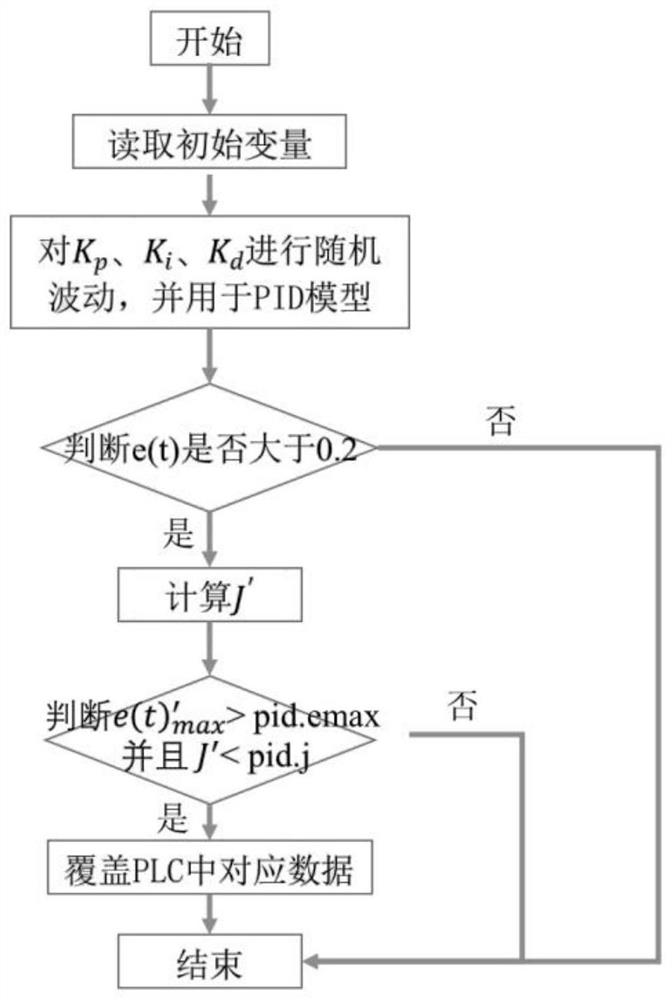

[0022] The method for controlling the elongation of a hot-dip galvanized four-roll temper mill according to the present invention will be further described below based on the specific embodiments and the accompanying drawings, but the specific embodiments and related descriptions do not constitute improper limitations to the technical solution of the present invention. The hot-dip galvanizing four-roller skin passer that the present invention relates to is as figure 1 Shown; The implementation logic diagram of the elongation control method of the hot-dip galvanized four-roll tempering machine is as follows figure 2 As shown, the method includes the following steps.

[0023] (1) start;

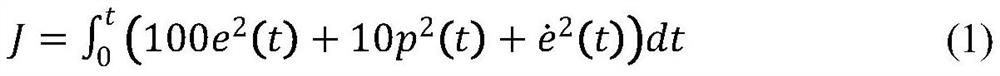

[0024] (2) The control system hardware selects the Logix5000 series PLC of AB Company, and adds five variables pid.kp, pid.ki, pid.kd, pid.emax, and pid.j to the global variables. The storage information of these five variables is respectively is the PID model parameter factor K p 、K i 、K ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com