Manufacturing process of multi-core fiber composite material internal orthogonal structural member, gel foaming material and special molding device thereof

A fiber composite material and foam material technology, applied in the field of fiber composite material processing and manufacturing, can solve problems such as no solution, and achieve the effects of reducing vibration and noise, high strength, excellent stability and shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0047] Preferred Embodiment 1: Application of Wind Power Generator Blades

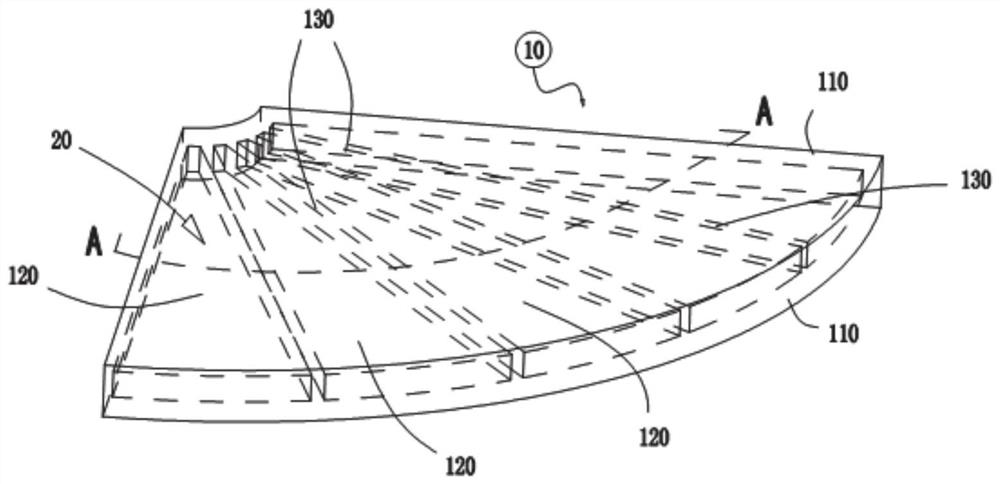

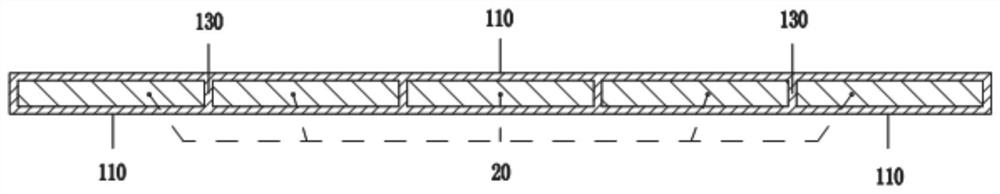

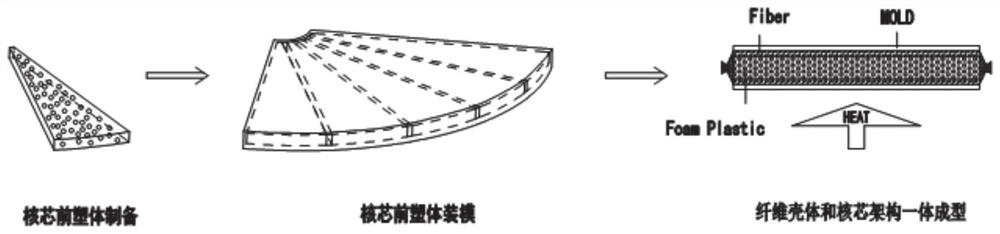

[0048] see figure 1 and figure 2 , the preferred embodiment of the present application discloses a fan-shaped multi-core fiber composite blade, which includes a closed shell 10, and the shell 10 includes two structural panels 110 (that is, blade panels), and the assembled wind generator When the rotor is used, the two structural panels 110 respectively form the front panel of the fan blade and the rear panel of the fan blade; the overall shape of the housing 10 is fan-shaped, and the surface area of the fan-shaped housing 10 is 6 times that of the existing strip-shaped fan blades of the same length. -10 times, the effective wind-catching area has been doubled.

[0049] Five cone-shaped core chambers 120 are arranged in the casing 10 , and the core chambers 120 extend along the radial direction of the casing 10 and are evenly distributed along the circumferential direction of the casing 10 . A cor...

Embodiment approach 2

[0061] Preferred Embodiment 2: Another Application of Wind Power Generator Blades

[0062] Figure 4 Shown is another embodiment of the multi-core fiber composite inner orthogonal structure and its manufacturing process of the present application. In this preferred embodiment, the core chamber 120 in the shell 10 and the core 20 filled in the core chamber 120 are in an annular structure as a whole, the core chamber 120 extends along the circumferential direction of the shell 10, and along the The radial direction of the casing 10 is evenly distributed. To adapt to the structural changes of the blades, the pre-core plastic body made of gel foam material in the core pre-core plastic body preparation step is also a ring structure; in the core pre-core plastic body molding step, the core The preplastic body also needs to be placed in a spatial layout that is evenly distributed along the radial direction and extends along the circumferential direction. Other aspects are the same...

Embodiment 3

[0063] Preferred Embodiment Three: Application of workshops, living rooms or other boards

[0064] In another preferred embodiment of the present invention, a high-strength, light-weight inner orthogonal plate-shaped structural member is disclosed. The plate-shaped inner orthogonal structural member can be a flat plate or an arc-shaped plate or a curved plate, and can be widely used It is used to make various boards, such as floors, wall panels, ceilings of living rooms or workshops, or shell structures of ships, vehicles, and equipment. see Figure 5 , the multiple core chambers in the housing are honeycomb structures. In other embodiments, of course, other multi-core space structures can also be developed, such as orthogonal or oblique grid structures, etc., multiple cores The chambers are evenly distributed within the shell, and the core chamber walls are normal to the faceplate of the shell. To adapt to the structural change, in the preparation step of the pre-core plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com