Quality detection device for LED production

A detection device and quality technology, applied in the field of quality detection devices for LED production, can solve problems such as low detection rate and complicated operation, and achieve the effect of preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

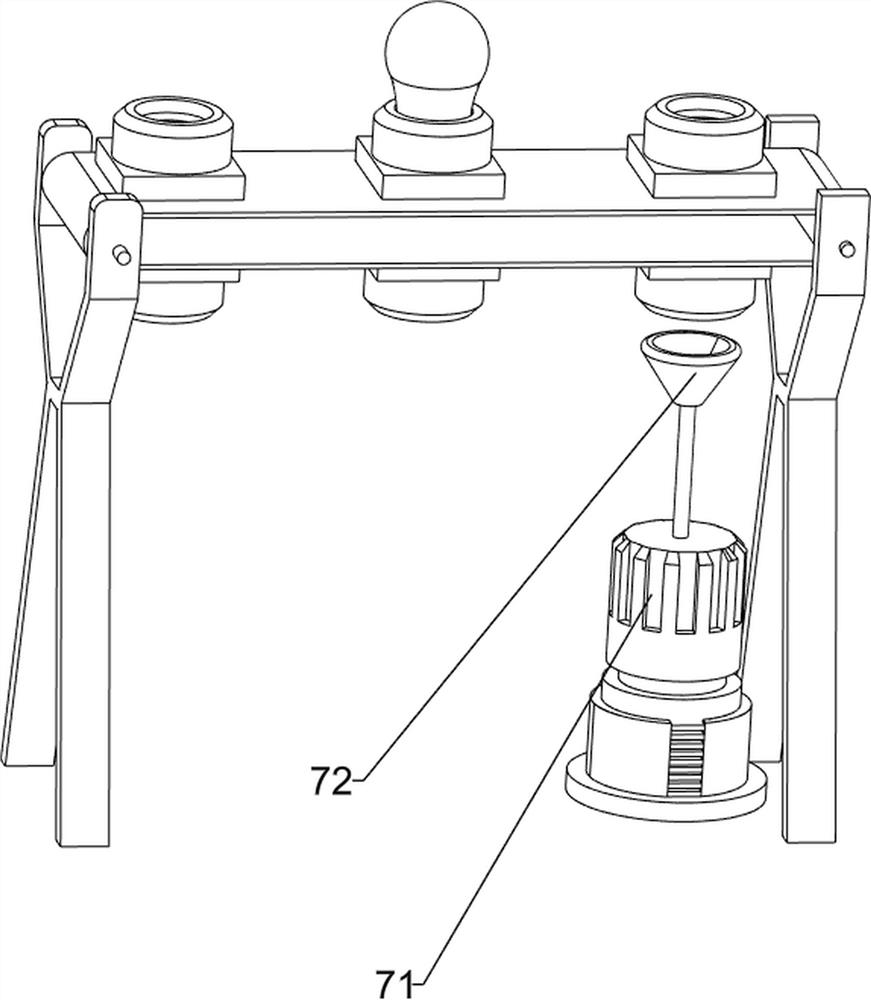

[0065] A quality inspection device for LED production, such as figure 1 As shown, it includes a base 1, a lifting mechanism 2 and a detection mechanism 3. The lifting mechanism 2 is connected to the front and rear sides of the upper part of the base 1, and the detection mechanism 3 is connected to the front and rear sides of the upper part of the base 1.

[0066] When the device needs to be used, the user can lift the light bulb between the lifting mechanism 2, start the lifting mechanism 2, the telescopic rod of the lifting mechanism 2 is extended, and drives the lifting mechanism 2 to move inward and upward, so as to provide The driving force is to facilitate the follow-up operation. When the lifting mechanism 2 moves up to contact with the detection mechanism 3, it pushes the detection mechanism 3 to move to the left. At this time, the detection mechanism 3 is compressed to detect the bulb, so as to achieve automatic detection of the bulb For the purpose of good or bad qual...

Embodiment 2

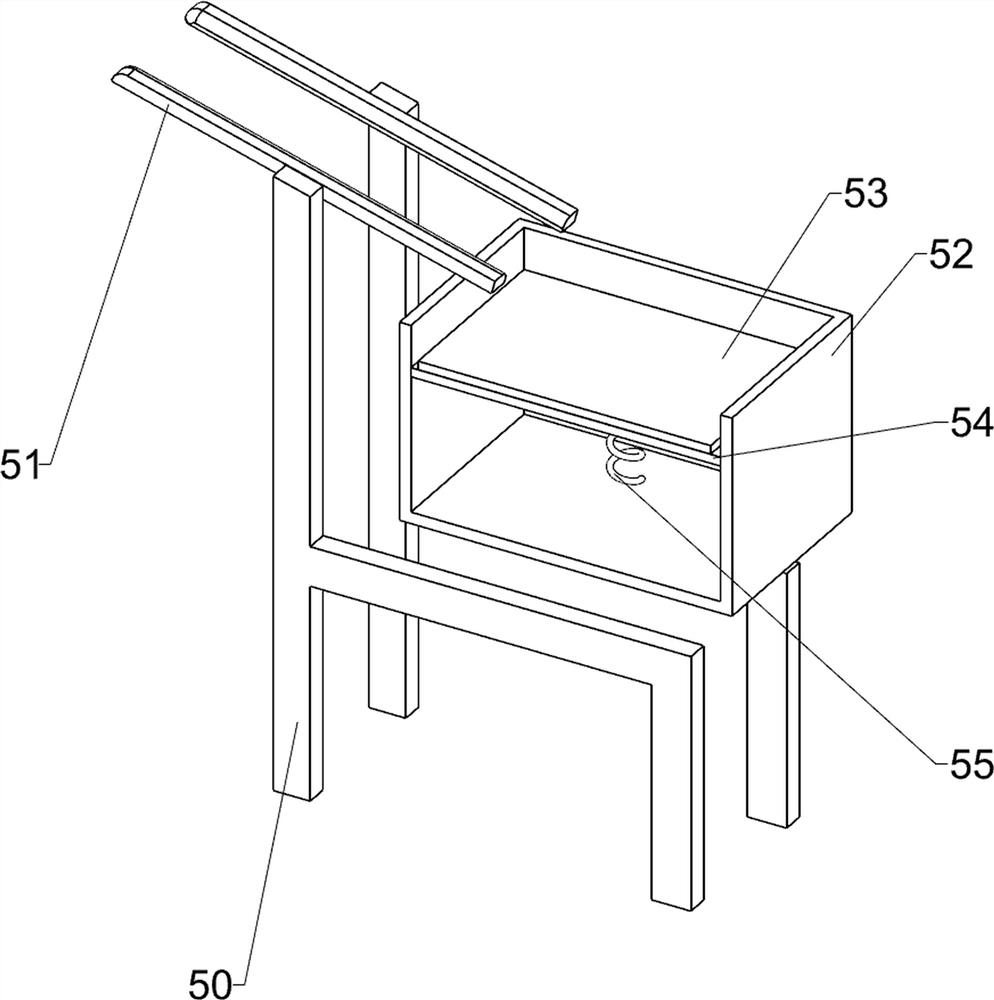

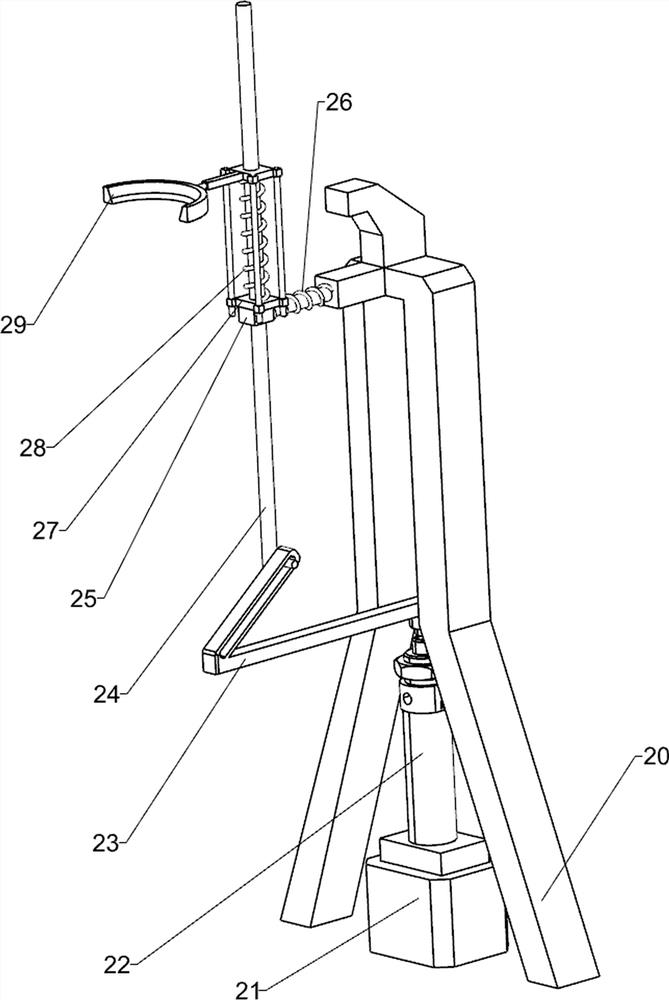

[0068] On the basis of Example 1, such as figure 2As shown, the lifting mechanism 2 includes a first support frame 20, a fixed seat 21, a cylinder 22, a push rod 23, a first spring 26, a sliding rod 24, a block 27, a sliding shaft 25, a second spring 28 and a block 29 , both sides of the upper part of the base 1 are connected with a first support frame 20, both sides of the upper part of the base 1 are connected with a fixed seat 21, the fixed seat 21 is connected with a cylinder 22, and the top of the output shaft of the cylinder 22 is connected with a Push rod 23, on the first support frame 20, all slide shafts 25 are slidably connected, and slide rods 24 are all slidably connected in the slide shafts 25, and slide rods 24 are slidably connected with push rods 23. A first spring 26 is wound around, and a block 27 is connected to the sliding rod 24, and a block 29 is slidably connected in the block 27, and the block 29 is slidably connected to the sliding rod 24, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com