Preparation method of biomass charcoal material

A technology of biochar and microwave absorbing materials, which is applied in the field of preparation of biochar materials, can solve the problems of uneven particle size, low efficiency, and tar generation of biochar materials, and achieve the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

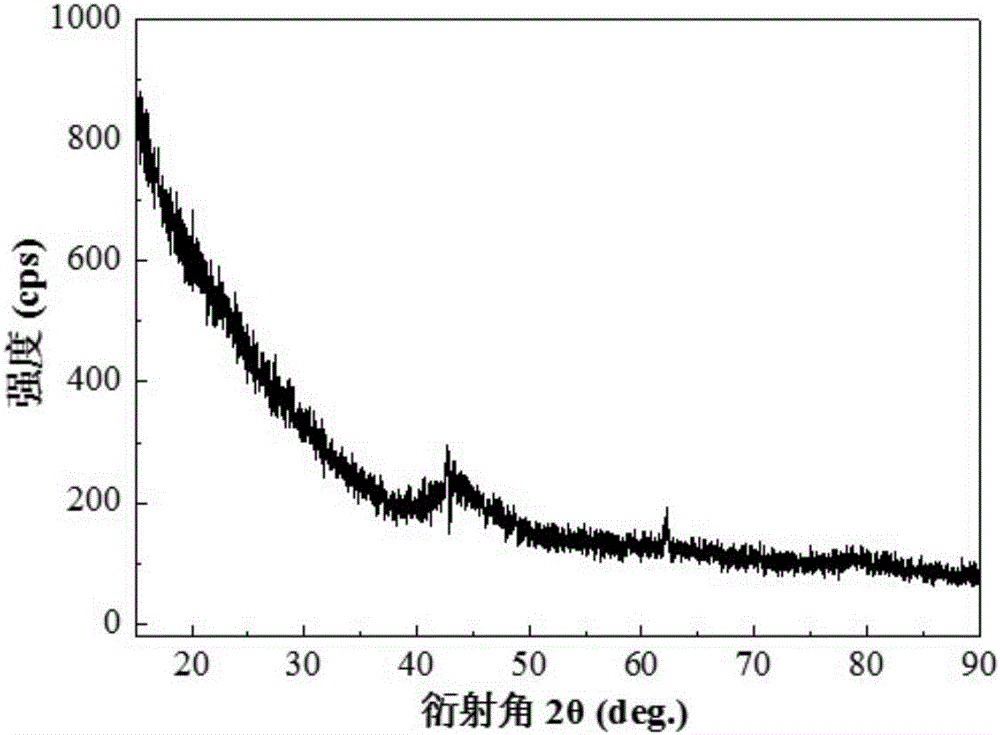

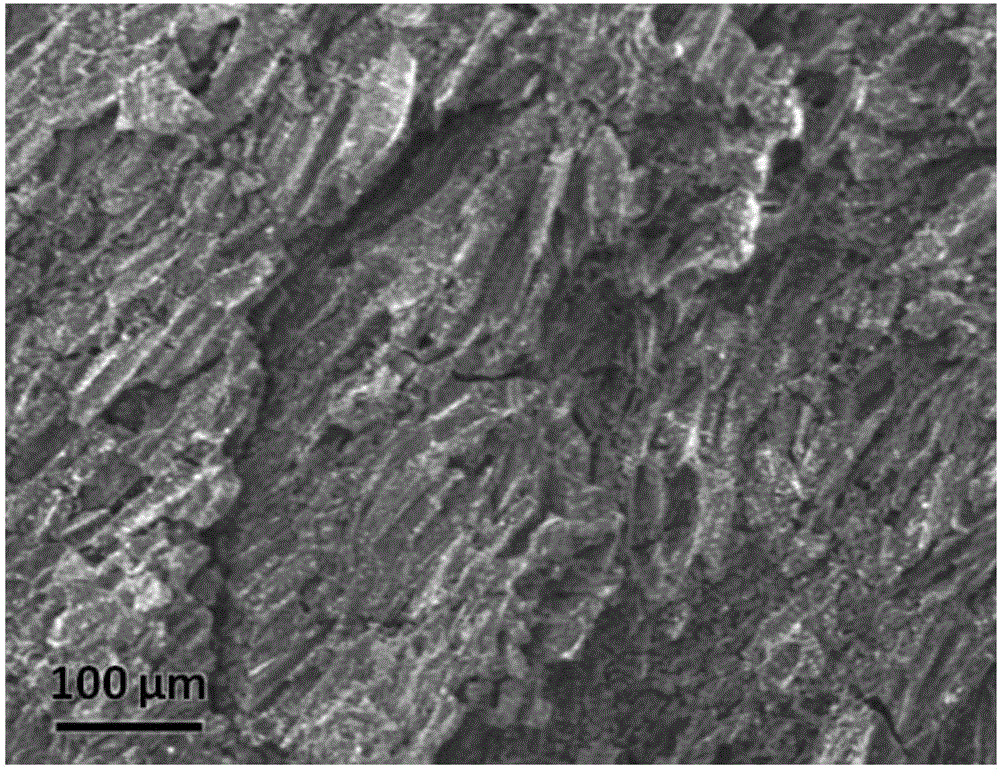

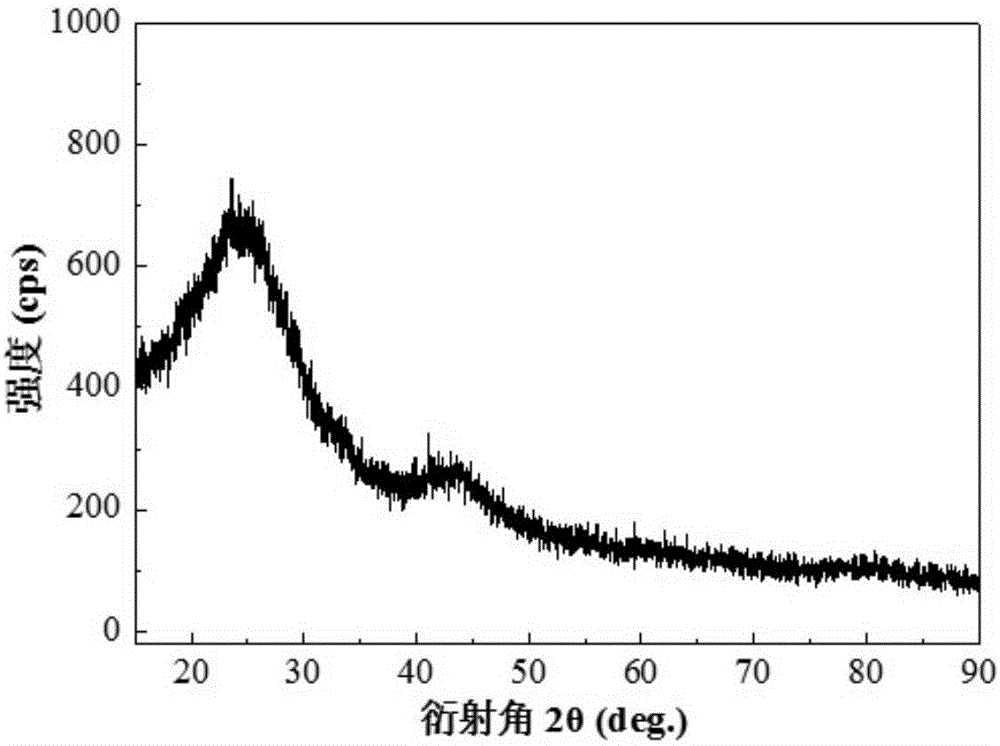

Image

Examples

Embodiment 1

[0034] The agricultural waste is dried, crushed, and sieved to obtain a precursor; the precursor is sealed in a crucible, and the crucible is placed in a microwave absorbing material, and the microwave absorbing material is heated by microwave to obtain a biomass charcoal material. In this embodiment, the microwave charcoal bath technology is used to place the substance to be heated in a thermally conductive container, that is, a crucible, and a microwave absorbing material is provided on the outside to absorb microwaves to rapidly increase the temperature, transfer the heat to the thermally conductive container, and then quickly heat The material in the crucible completes the preparation of the biomass charcoal material. The preparation method heats quickly, has a short reaction time, does not produce tar, and facilitates subsequent processing; it also does not require a protective atmosphere, making the operation process more convenient.

Embodiment 2

[0036] Compared with Example 1, the agricultural waste in this example is straw, the skin of agricultural products, the core of agricultural products, or processed agricultural wastes.

Embodiment 3

[0038] Compared with Example 1, the drying in this example is mechanical drying, and the moisture content of the agricultural waste after drying is less than or equal to 5% in terms of mass percentage.

[0039] Because the microwave heating method is used in the present invention, and no protective atmosphere is used to protect the heated precursor, the moisture in the raw materials must be strictly controlled to avoid oxidation reactions and reduce the quality of the products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com