A method for precise control of real-time aeration in sewage treatment process based on activated sludge

A technology of activated sludge and sewage, applied in water treatment parameter control, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as high energy consumption, extensive control, and imperfect biological mechanism, etc. Achieve the effect of stabilizing the biochemical treatment system, overcoming the large hysteresis, and overcoming the roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

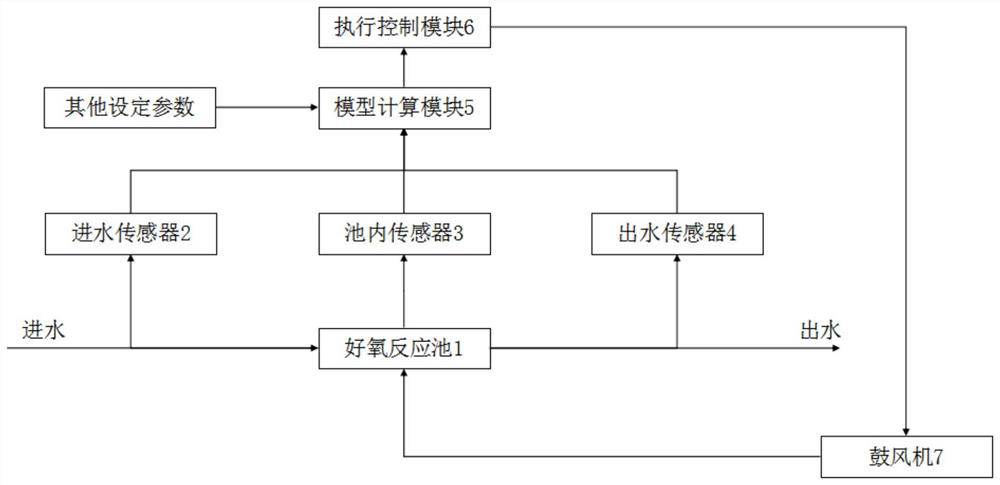

[0041] 1. Schematic diagram of the control process

[0042] figure 1 It is a schematic diagram of the control process of the real-time aeration precise control method in the sewage treatment process based on activated sludge in the present invention. The sewage treatment device includes an aerobic reaction tank 1 and a blower 7 for aerating the aerobic reaction tank 1. The water sensor 2, the sensor in the pool 3, the water outlet sensor 4, the model calculation module 5, and the execution control module 6; the water inlet sensor 2, the inside sensor 3 and the water outlet sensor 4 are all connected to the model calculation module 5 circuit; the model calculation module 5 is connected to the execution control module The module 6 is connected to the circuit; the executive control module 6 is connected to the blower 7.

[0043] The influent sensor 2 is set at the inlet end of the aerobic reaction tank 1, including the influent water quantity Q sensor, the influent dissolved oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com