A method for generating red pigment by using mustard knots as raw materials

A mustard pimple and red pigment technology, which is applied in the field of red pigment generation, can solve the problems of industrialization development constraints, lack of deep-processing products, and high labor intensity, so as to improve utilization rate and economic value, broaden the range of raw material selection, and solve problems that cannot be solved. The effect of long-term storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

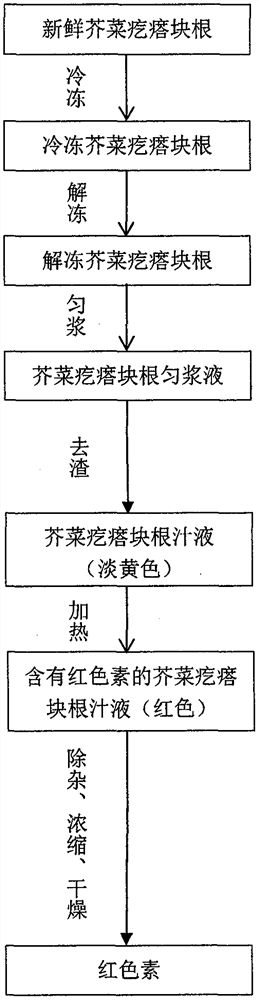

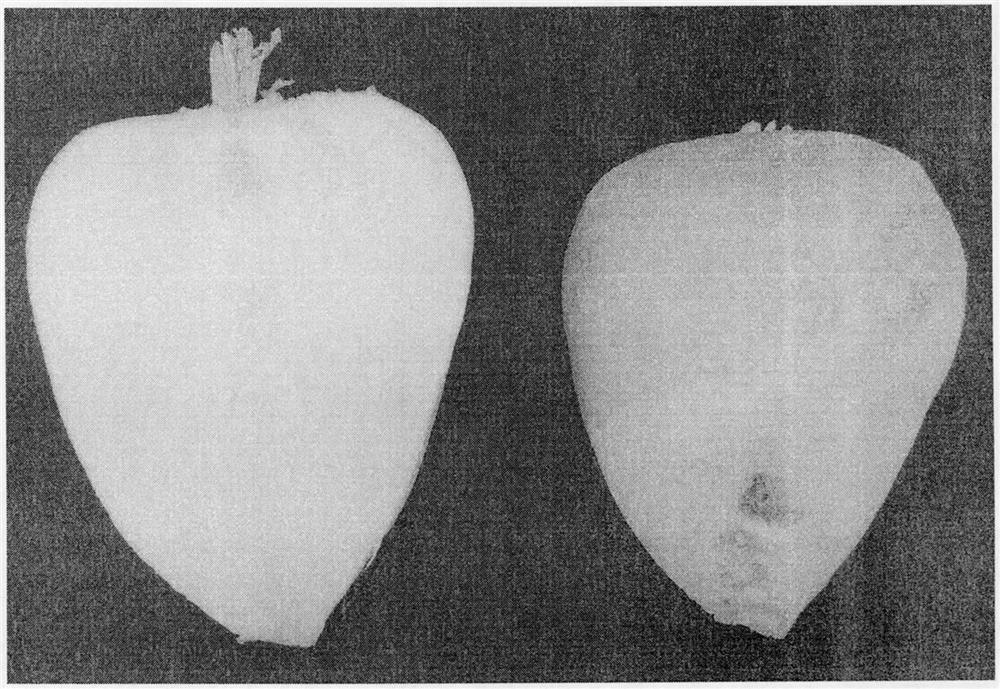

[0023] (1) Take 1000g of cleaned fresh mustard root tubers and freeze them for more than 24 hours at a low temperature of -20°C to -30°C.

[0024] (2) Completely thaw the frozen mustard nodules under normal temperature conditions.

[0025] (3) Homogenize the completely thawed mustard nodules under the condition of a rotating speed of 8000 r / min, and filter the homogenate to remove slag to obtain mustard nodules juice.

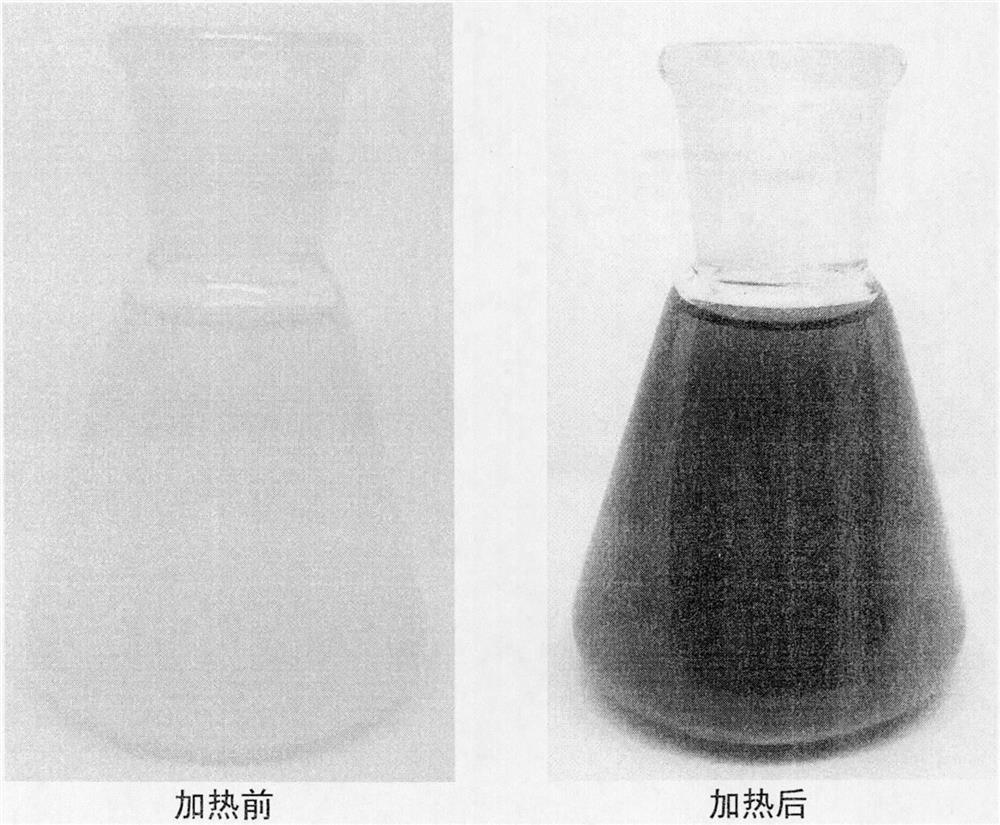

[0026] (4) Stir and heat the mustard tuber root juice at a high temperature of 80°C to 90°C until the juice changes from light yellow to red, and continue to stir and heat for no less than 1 hour.

[0027] (5) The red juice is centrifuged to remove impurities, concentrated and dried to obtain red pigment.

[0028] Through the above process steps, 19.92 g of red pigment can be prepared from 1000 g of mustard nodules, and the yield of red pigment is 1.99%. After structural identification, the main component of red pigment is peony anthocyanin.

Embodiment 2

[0030] (1) Take 1000g of cleaned fresh mustard root tubers and freeze them for more than 24 hours at a low temperature of -20°C to -30°C.

[0031] (2) Completely thaw the frozen mustard nodules under normal temperature conditions.

[0032] (3) Homogenizing the completely thawed mustard tuber roots under the condition of a rotating speed of 10000 r / min, and filtering the homogenate to remove slag to obtain mustard tuber root juice.

[0033] (4) Stir and heat the mustard root tuber juice at a high temperature of 90°C to 100°C until the juice changes from pale yellow to red, and continue to stir and heat for no less than 1 hour.

[0034] (5) The red juice is centrifuged to remove impurities, concentrated and dried to obtain red pigment.

[0035] Through the above process steps, 20.06 g of red pigment can be prepared from 1000 g of mustard nodules, and the yield of red pigment is 2.00%. After structural identification, the main component of red pigment is peony anthocyanin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com