Drill rod centralizing ring and drilling device for horizontal drilling

A drilling device and horizontal drilling technology, which is applied in the direction of drill pipes, drilling equipment and methods, and drill pipes, and can solve the problems that the drill pipe cannot be centered closely, the mud circulation effect in the hole is not good, and the drilling pressure loss, etc. problem, to achieve the effect of good circulation effect, good promotion significance, and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

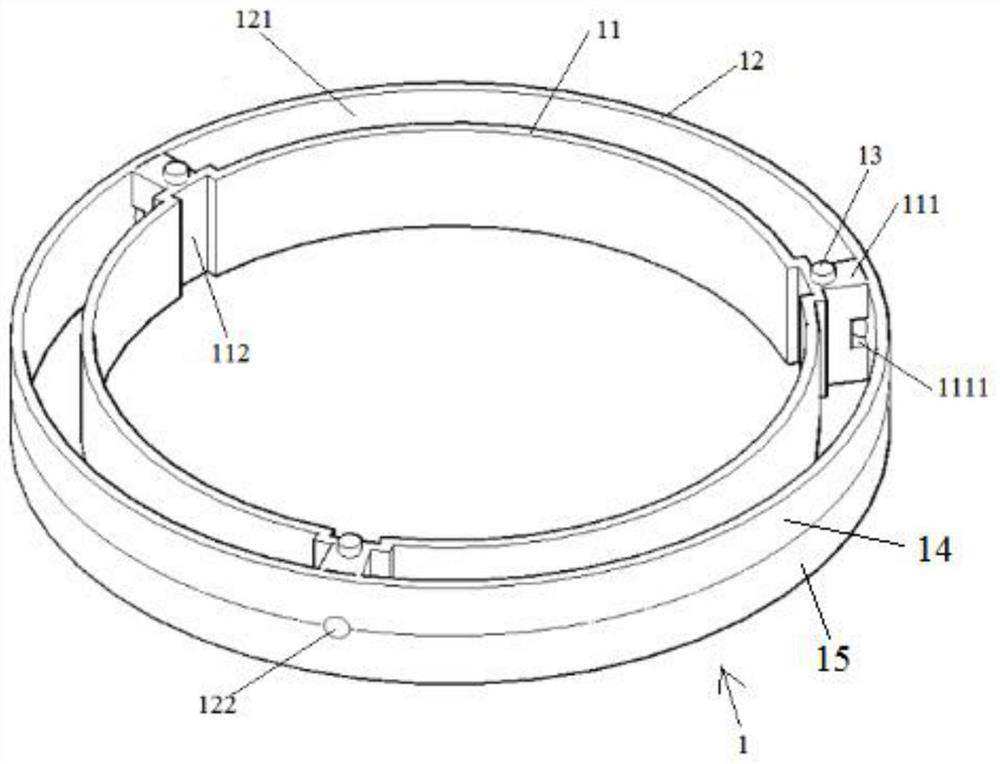

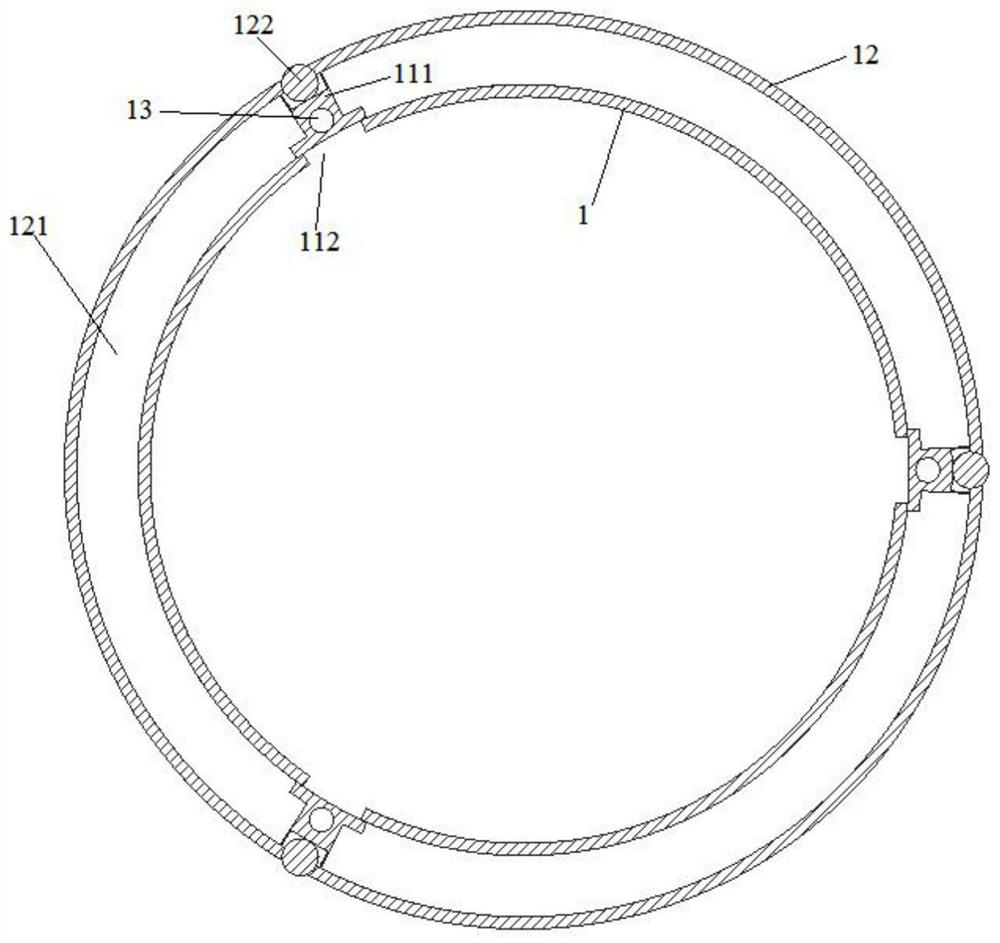

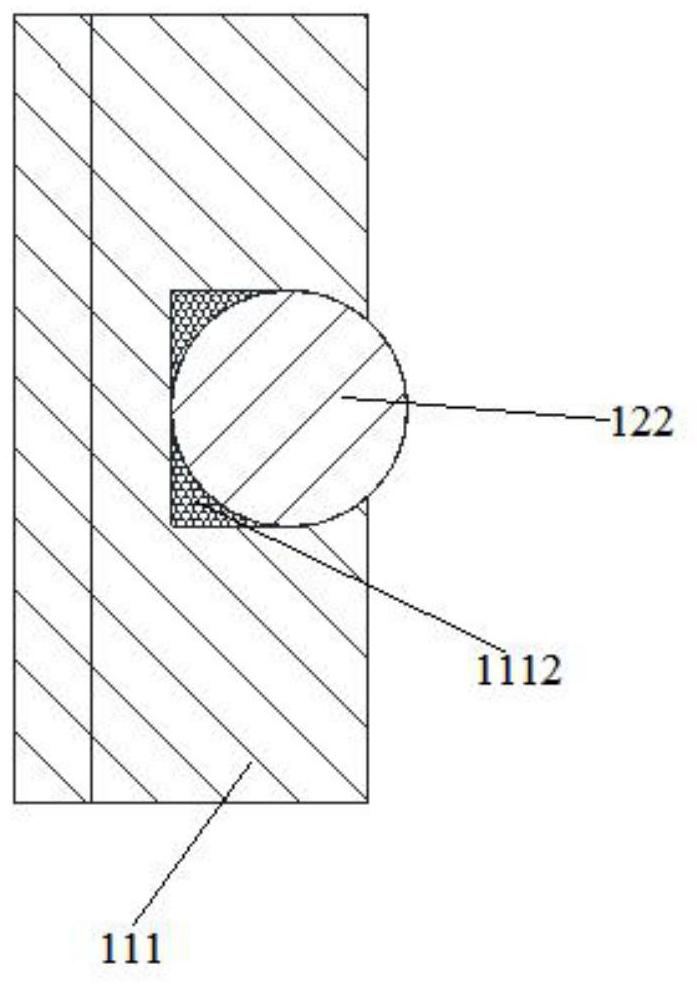

[0054] Such as figure 1 and figure 2 As shown, a drill pipe centering ring 1 includes an inner ring 11 and an outer ring 12 arranged concentrically. There are three connecting pedestals 111 connected therebetween, and the connecting pedestals 111 are evenly spaced along the circumferential direction of the inner ring 11 . The gap area formed between the inner ring 11 and the outer ring 12 is a mud circulation channel 121 . Such as figure 1 As shown, the drill pipe centralizing ring 1 includes a first centralizing body 14 and a second centralizing body 15 arranged symmetrically. The first centralizing body 14 and the second centralizing body 15 are two symmetrical rings, which are fixed by screws 13 after being combined. Drill pipe centralizing ring 1, the matching connecting surface of the first centralizing body 14 and the second centralizing body 15 is the cross section of the drill pipe centralizing ring 1, the first centralizing body 14 and the second centralizing body...

Embodiment 2

[0061] A drilling device for horizontal drilling, comprising a drill bit, a drill pipe 2 and two spaced drill pipe centering rings 1 shown in Embodiment 1 which are set and fixed on the drill pipe 2, the drill bit is installed on the drill pipe end of rod 2. Such as Figure 4 As shown in the schematic diagram of the structural relationship between the drill pipe 2 and the drill pipe centralizing ring 1, the drill pipe centralizing ring 1 is sleeved on the drill pipe 2 and is fixedly connected by a pin key 113. The drilling device provided by the present invention can be used for surveying small-diameter Long-distance directional horizontal drilling operations have good promotional significance.

Embodiment 3

[0063] This embodiment provides the installation steps of the drilling device of Embodiment 2, including the following steps:

[0064] Step A. Install the drill pipe centralizing ring 1: first place three movable steel balls 122 in sequence in the cavity connecting the pedestal 111 of the second centralizing body 15, and then place the first centralizing body 14 symmetrically on the second centralizing body 15 First, fix the first centralizer 14 and the second centralizer 15 with screws, and then install mud filter screens 1112 at the two ends of the cavity 1111 connected along the circumferential direction of the outer ring;

[0065] Step B, then the drill pipe 2 is passed through the inner ring 11 of the drill pipe centralizing ring 1; the pin key 113 is inserted into the pin key groove 112 of the inner ring 11, the two ends of the pin key groove 112 all leak out the pin key 113, Then the screw is inserted into the threaded hole provided on the outer leaking pin key at the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com