Ship welding management and control system and method based on communication network

A technology of communication network and management and control system, applied in the field of ship welding management and control system based on communication network, can solve problems such as easy loss of welding data, and achieve the effects of strong data processing capability, accurate evaluation model and increased data volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

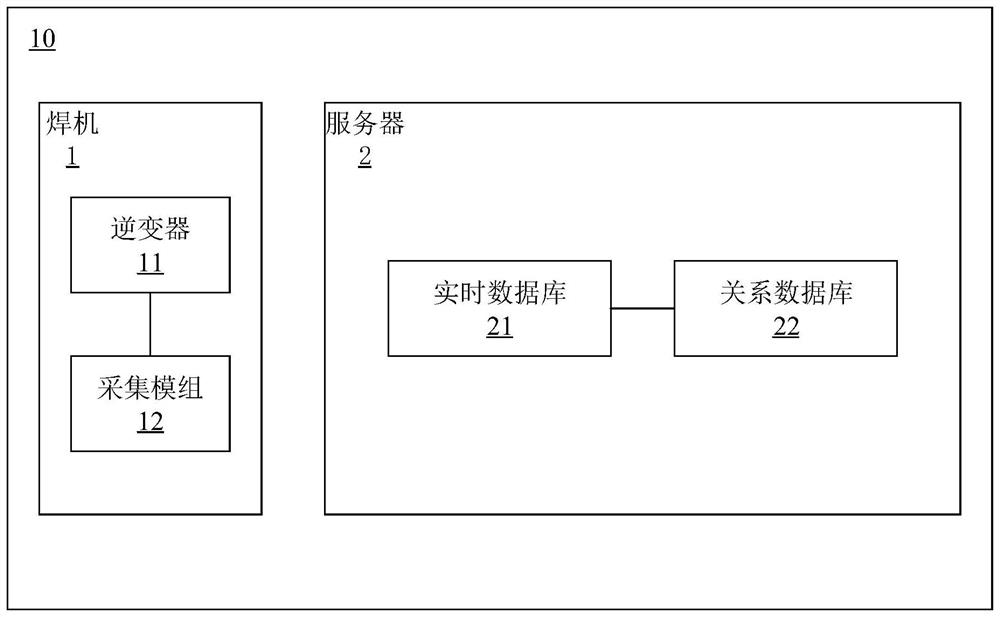

[0044] This embodiment provides a communication network-based ship welding management and control system, including:

[0045] At least two welding machines and a server communicating with the welding machines; a real-time database is set in the servers;

[0046] Each of said welders includes:

[0047] The inverter is used to send the real-time working parameters of the welding machine according to the sending frequency;

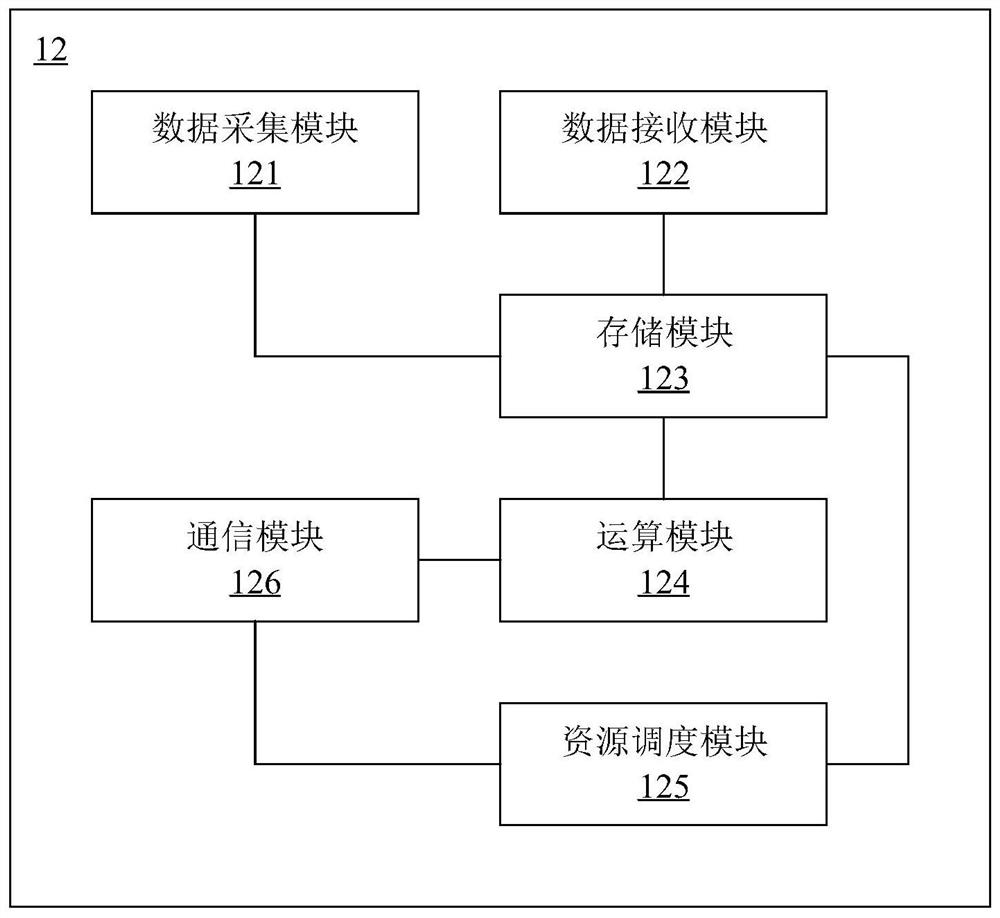

[0048] A collection module, connected with the inverter; wherein, the collection module includes:

[0049] a data acquisition module for acquiring real-time working parameters of the welding machine from the inverter;

[0050] a data receiving module, used for receiving the welding posture of the welder, the width of the weld gap, the surface flatness of the weld, and the timing of the droplet falling off from the welder sent from the real-time database;

[0051] The arithmetic module is used to use the real-time working parameters of the welding machine col...

Embodiment 2

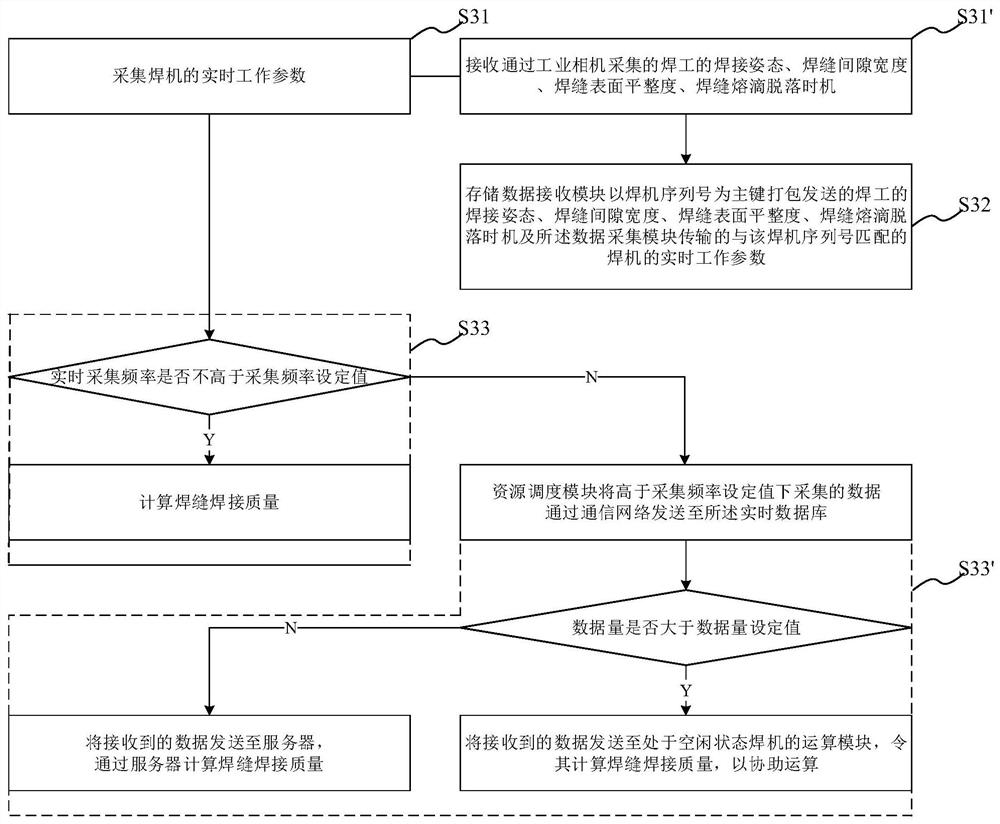

[0093] This embodiment provides a communication network-based ship welding management and control method, which is applied to a communication network-based ship welding management and control system; the communication network-based ship welding management and control system includes at least two welding machines and a communication connection with the welding machines. The server, the server sets a real-time relationship database; the communication network-based ship welding management and control method includes:

[0094] Collect real-time working parameters of the welding machine;

[0095] Receive the welding posture of the welder, the width of the weld gap, the flatness of the weld surface, and the timing of the droplet falling off;

[0096] When the real-time acquisition frequency is not higher than the set value of the acquisition frequency, use the acquired real-time working parameters of the welding machine and the welding posture of the welder, the width of the weld ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com