Two-stage operation optimization method for distributed system

A distributed system and operation optimization technology, which is applied in the field of two-stage operation optimization for distributed systems, can solve the problems of reduced operating efficiency of main equipment, difficulty in ensuring equipment scheduling feasibility, and difficulty in achieving energy utilization in the system. Profit maximization, good equipment scheduling feasibility, economical and operational feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

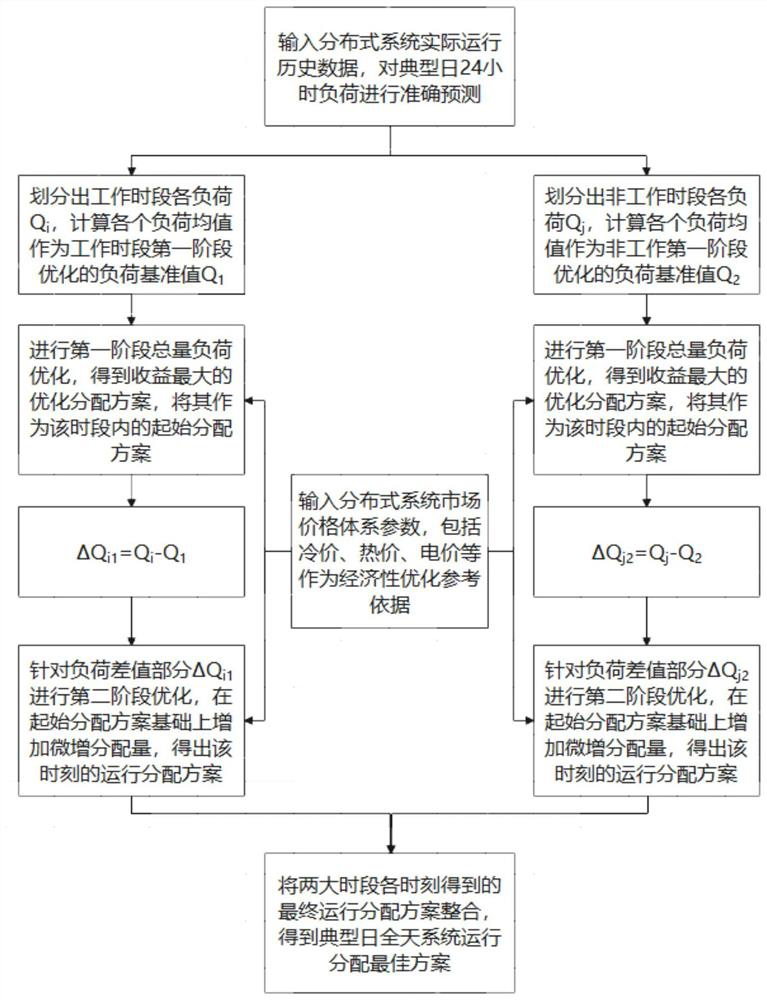

[0034] refer to figure 1 , which is the first embodiment of the present invention, provides a two-stage operation optimization method for distributed systems, including:

[0035] S1: Predict hourly cooling and heating load changes in typical days based on historical operating data, and divide typical days into working hours and non-working hours. It should be noted that the forecast includes:

[0036] By inputting the hourly operating data of the distributed system in the actual park in the past years, the hourly change curve of the cooling and heating load is obtained;

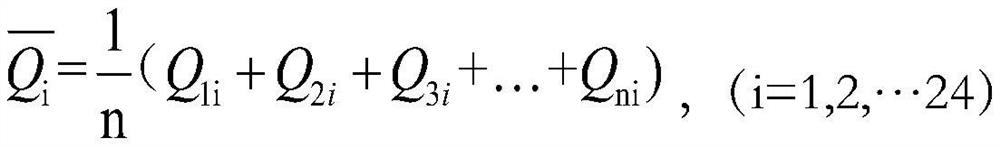

[0037] According to the demand in a single season, define the load change data at 24 times in n days, and average the load at the same time in each day as the predicted load at each time in a typical day of the season, as follows,

[0038]

[0039] in, is the predicted load of the system at time i, n is the number of days when the system operation data in the actual project has a typical and representa...

Embodiment 2

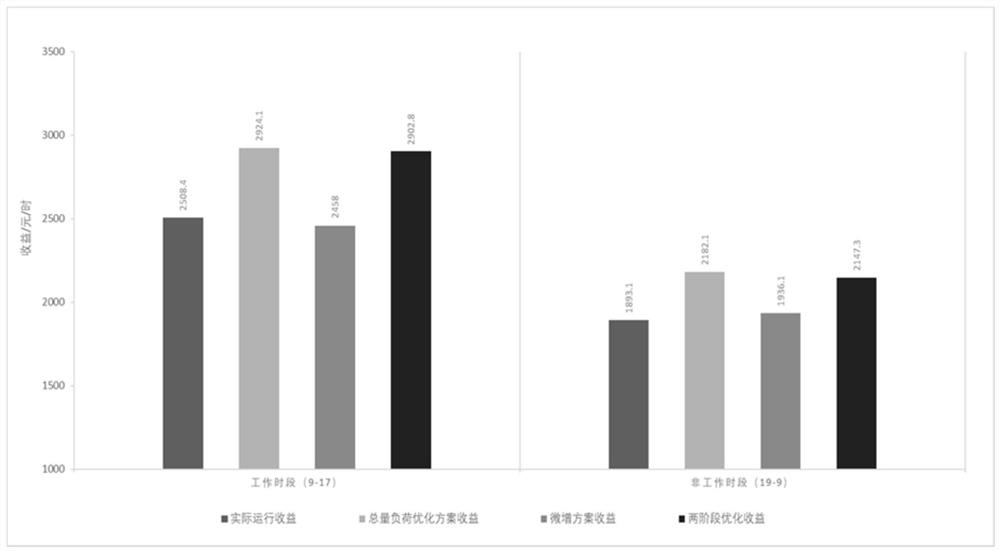

[0069] refer to figure 2 , is the second embodiment of the present invention. This embodiment is different from the first embodiment in that it provides an experimental verification of a two-stage operation optimization method for a distributed energy supply system, specifically including:

[0070] This embodiment applies the above-mentioned optimization scheme (i.e. the technical scheme of Embodiment 1) to optimize the operation of the distributed system in an amusement park area in Shanghai on a typical day in summer. The demand determines the unit capacity configuration, and the power generation is determined according to the unit capacity. Therefore, the distribution of cooling, heating, and electricity loads in the park is actually a distribution between cooling and heating loads.

[0071] By investigating the specific data of the distributed system operation in the park in previous years, the hourly change curve of the typical daily cooling and heating load in summer is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com