Classification and separation method for potassium feldspar ore

A kind of potassium feldspar and sorting technology, applied in the field of potassium feldspar mineralization and recovery, can solve the problems of weakening the source properties of potassium feldspar, insufficient dissociation, energy waste of flotation recovery efficiency, etc., and achieve high The value of industrial promotion and application, the maximization of economic benefits, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

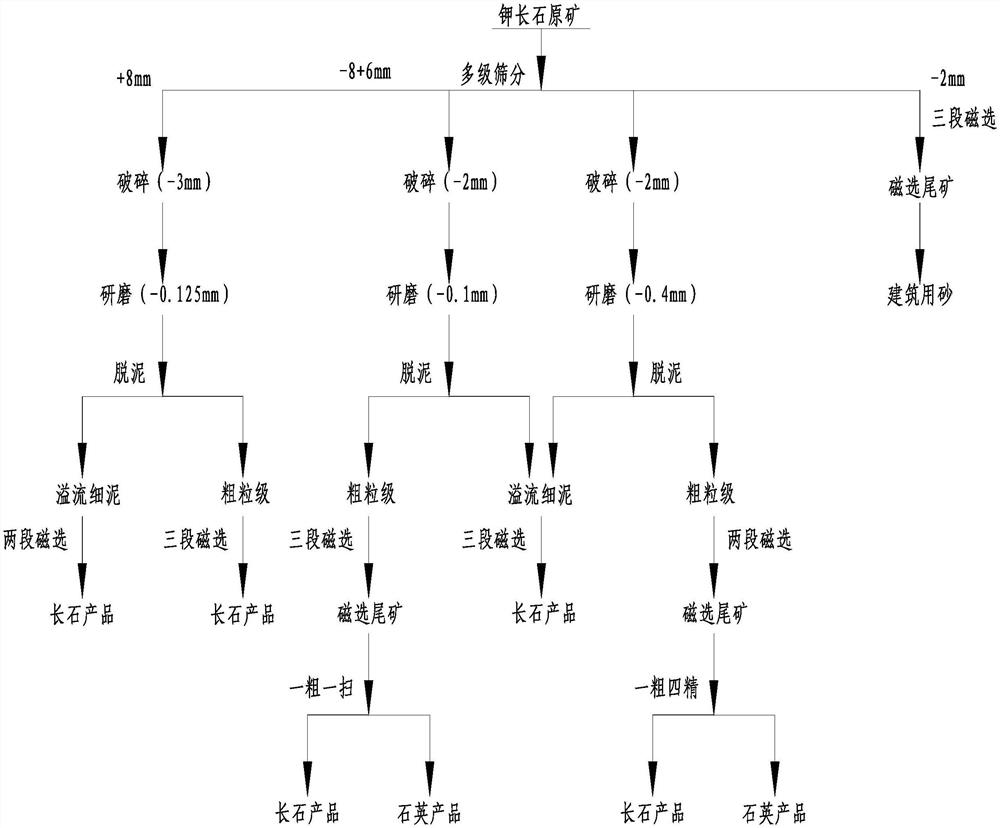

[0026] A kind of technological method of classification and separation of potassium feldspar ore, the main technological process is as follows figure 1 As shown, it specifically includes the following steps:

[0027] (1) Raw ore screening and material grade analysis of each particle size: use 12mm, 8mm, 6mm, 4mm, 2mm, 1mm, 0.5m and 0.1mm sieves to screen potassium feldspar raw ore, and then obtain +12mm, - 12+8mm, -8+6mm, -6+4mm, -4+2mm, -2+1mm, -1+0.5mm, -0.5+0.1mm and -0.1mm grade potassium feldspar ore; After the particle size materials are respectively ground to less than 200 microns, the element composition and content are tested respectively by X-ray fluorescence;

[0028] (2) Sorting particle size merger: according to the potassium oxide (K 2 (0) grade, the adjacent grade potassium feldspar mines with close grades are combined, and combined with the yield of each grade to finally determine the K between each grade from coarse to fine. 2 The segmentation granularity o...

Embodiment 2

[0036] A classification and separation method for potassium feldspar ore, comprising the following steps:

[0037] (1) Sieve the potassium feldspar ore, and the sieving particle size is 12mm, 8mm, 6mm, 4mm, 2mm, 1mm, 0.5mm and 0.1mm, and then grind the samples to a certain size, and use X-ray fluorescence Spectrum and MLA mineral automatic detection system to test the elemental composition and mineral content of samples of each particle size;

[0038] (2) According to K in each particle size 2 O grade and content of impurity mineral feldspar (the main occurrence mineral of calcium element) determine the suitable grading particle size, and the separation point of the sorting particle size determined accordingly is 8mm, 6mm and 2mm; after calculation, +8mm, -8+6mm , -6+2mm and -2mm potassium feldspar ore K 2 O grades are 8.51%, 7.52%, 4.10% and 3.47% in turn.

[0039](3) The +8mm potassium feldspar ore goes through the process of "crushing - grinding - desliming - magnetic se...

Embodiment 3

[0046] A kind of classification separation method of potassium feldspar ore, it is characterized in that, comprises the following steps:

[0047] (1) Sieve the potassium feldspar ore, and the sieving particle size is 12mm, 8mm, 6mm, 4mm, 2mm, 1mm, 0.5mm and 0.1mm, and then grind the samples to a certain size, and use X-ray fluorescence Spectrum and MLA mineral automatic detection system to test the elemental composition and mineral content of samples of each particle size;

[0048] (2) According to K in each particle size 2 O grade and content of impurity mineral feldspar (the main occurrence mineral of calcium element) determine the suitable grading particle size, and the separation point of the sorting particle size determined accordingly is 8mm, 6mm and 2mm; after calculation, +8mm, -8+6mm , -6+2mm and -2mm potassium feldspar ore K 2 O grades are 8.40%, 7.41%, 4.00% and 3.41% in turn.

[0049] (3) The +8mm potassium feldspar ore goes through the process of "crushing - gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com