Condenser acoustic shield

A technology of sound insulation cover and condenser, which is applied in the direction of instruments, sounding equipment, chemical instruments and methods, etc., can solve the problem of condenser noise easily exceeding the standard, so as to improve the overall sound insulation and impact resistance performance, prevent easy damage, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

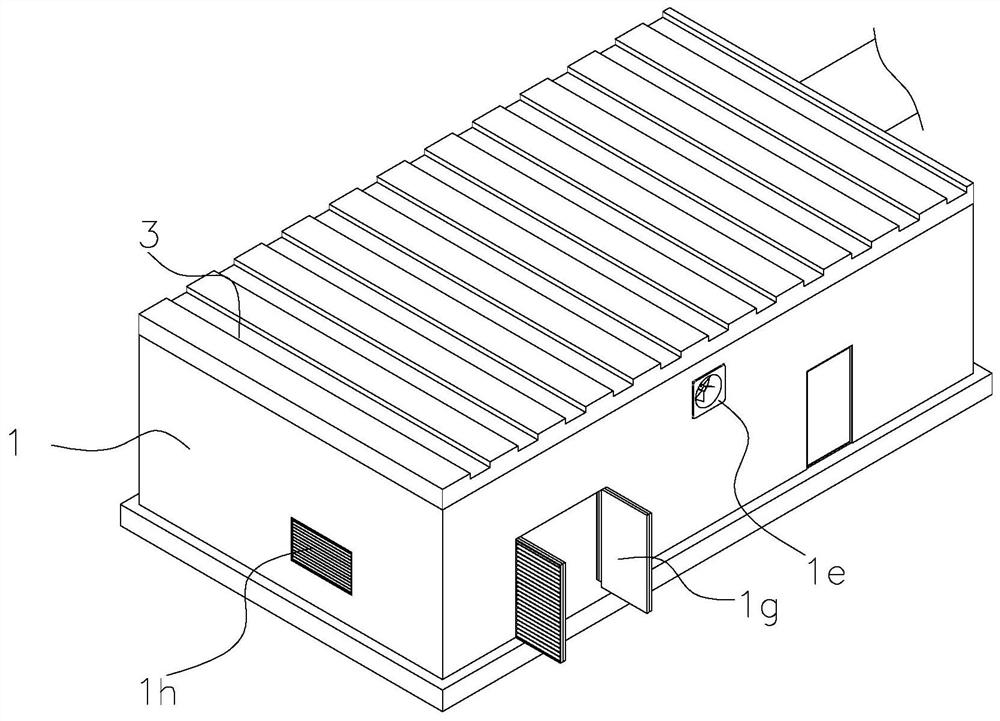

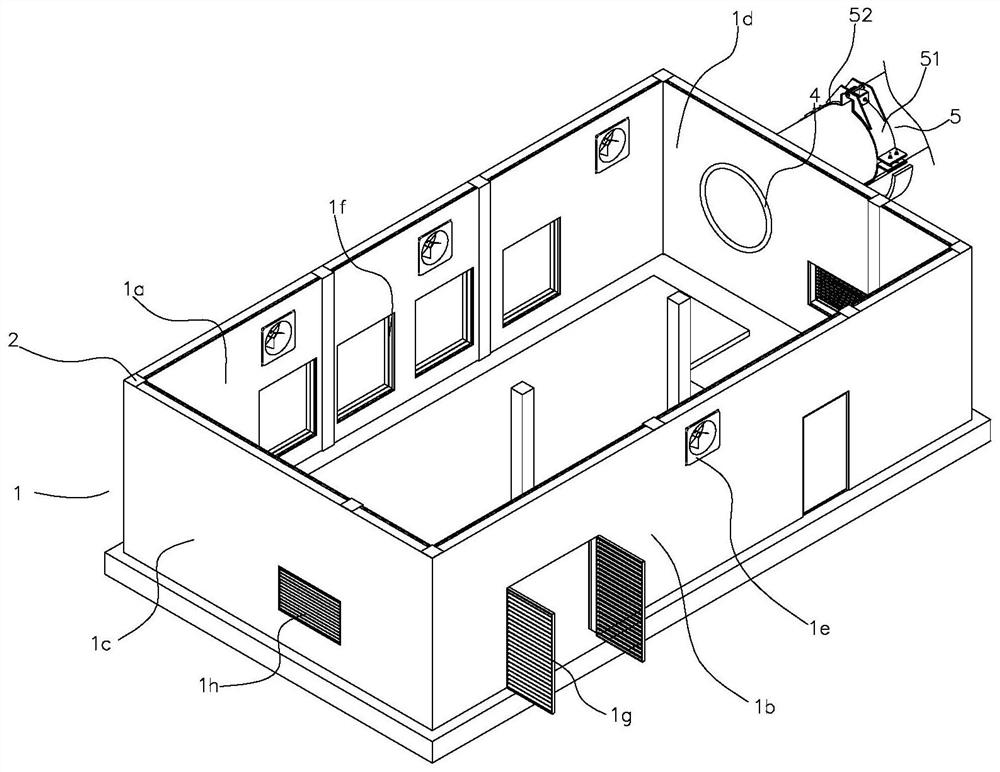

[0039] refer to Figure 1 to Figure 14 , the present embodiment provides a condenser sound insulation cover, including a plurality of peripheral panels 1 distributed in a rectangular shape, support columns 2 fixed between the peripheral panels 1 and a top plate 3 fixed on the top of the peripheral panels 1,

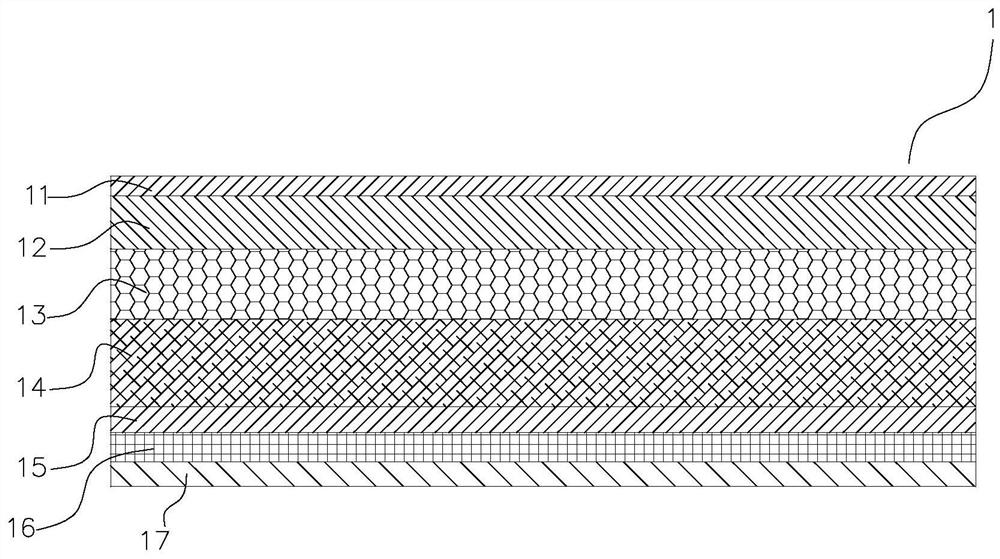

[0040] The peripheral panel 1 includes first galvanized plate 11, centrifugal glass wool 12, honeycomb aluminum plate 13, damping sound insulation felt 14, cement fiber board 15 and second galvanized plate 16 from top to bottom. It includes a solid plate 131, a pentagonal edge 132 formed by a plurality of edges fixed on one side of the solid plate 131, and a hexagonal edge formed by a plurality of edges fixed on one side of the pentagonal edge 132 133, a plurality of pentagonal edges 132 and a plurality of hexagonal edges 133 form two horizontal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com