Lithium battery module integrated with liquid cooling function

A lithium battery, integrated liquid technology, used in secondary batteries, circuits, electrical components, etc., can solve the problems of high efficiency reaching target requirements, poor cooling effect, etc., to improve cooling efficiency, reduce thermal resistance, and reduce temperature differences sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

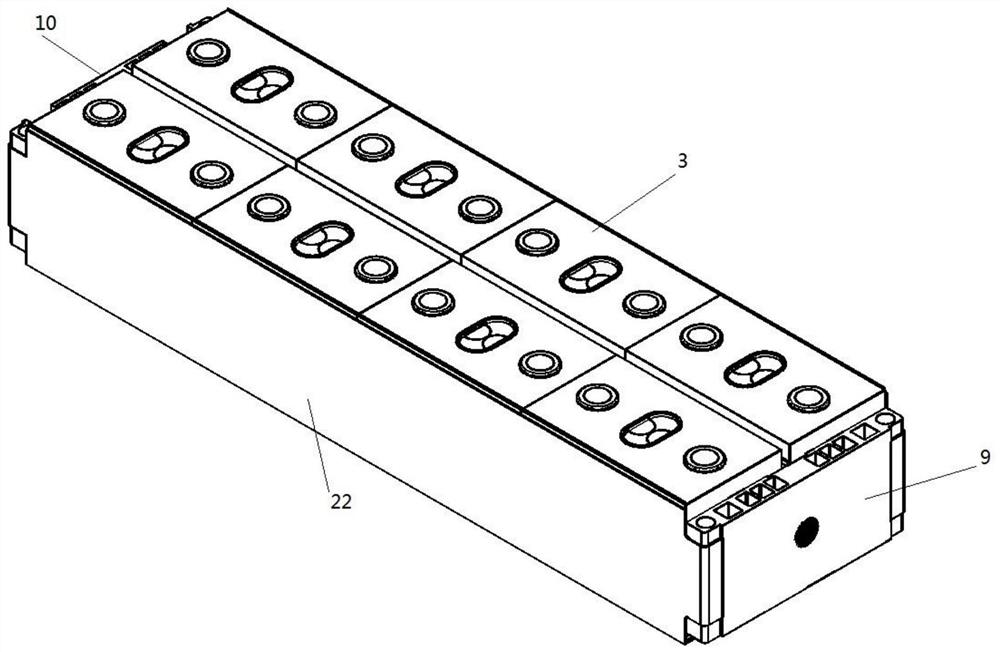

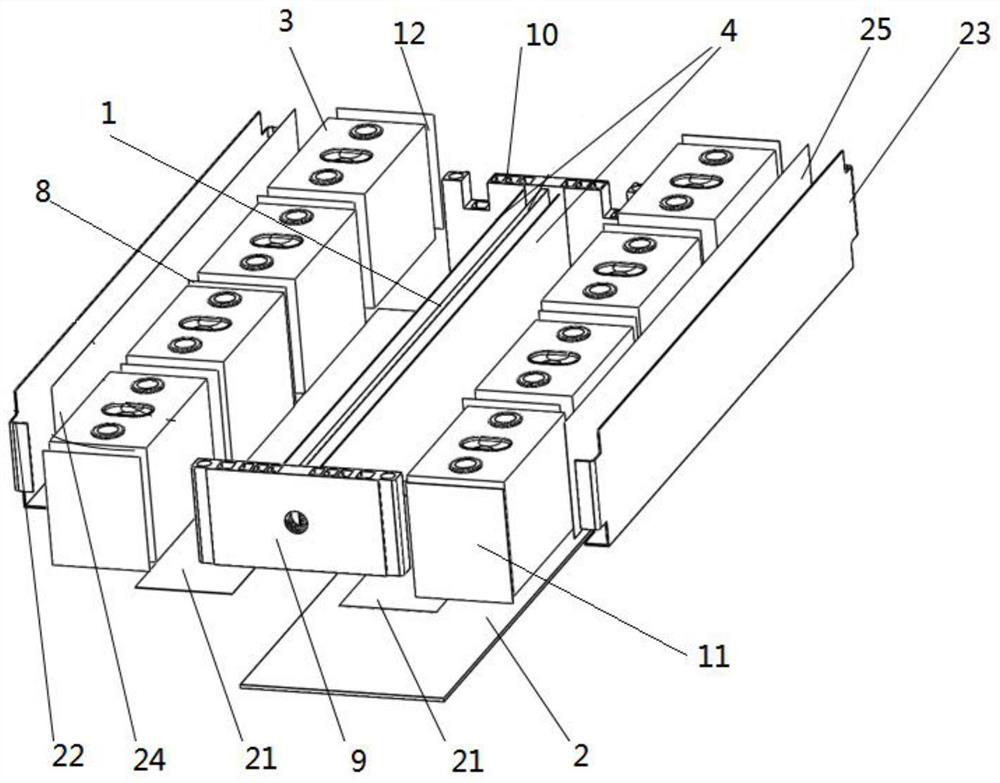

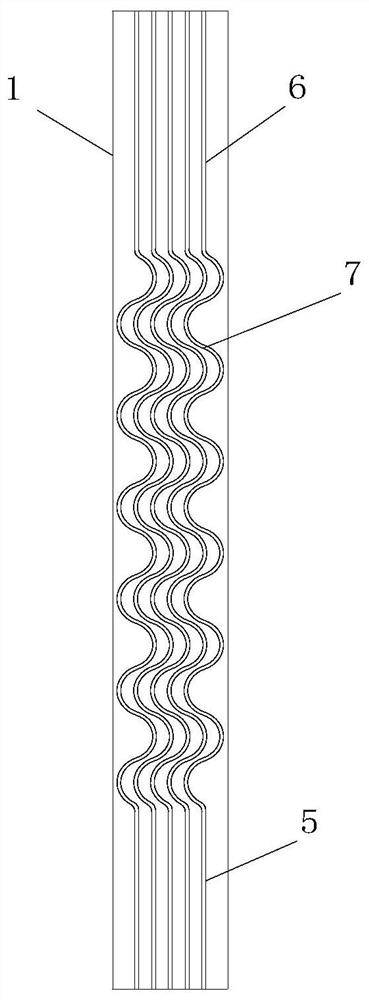

[0021] refer to Figure 1-Figure 5 , the present invention proposes a lithium battery module with integrated liquid cooling function, including a liquid cooling plate 1 and a bottom plate 2, the bottom plate 2 is arranged horizontally, the liquid cooling plate 1 is vertically arranged and the liquid cooling plate 1 and the bottom plate 2 are vertically connected, and the liquid cooling The plate 1 is provided with a plurality of cooling liquid flow channels arranged along its length direction and passing through at intervals. The cooling liquid flow channels include a first straight flow channel 5, a wave-shaped flow channel 7, and a second straight flow channel 6 arranged in sequence. The wall thickness of the cold plate 1 is ≥2mm. A plurality of lithium battery cells 3 arranged side by side are arranged on both sides of the liquid cooling plate 1 in the longitudinal direction on the bottom plate 2 , and thermal conductive glue 4 is applied between both sides of the liquid co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com