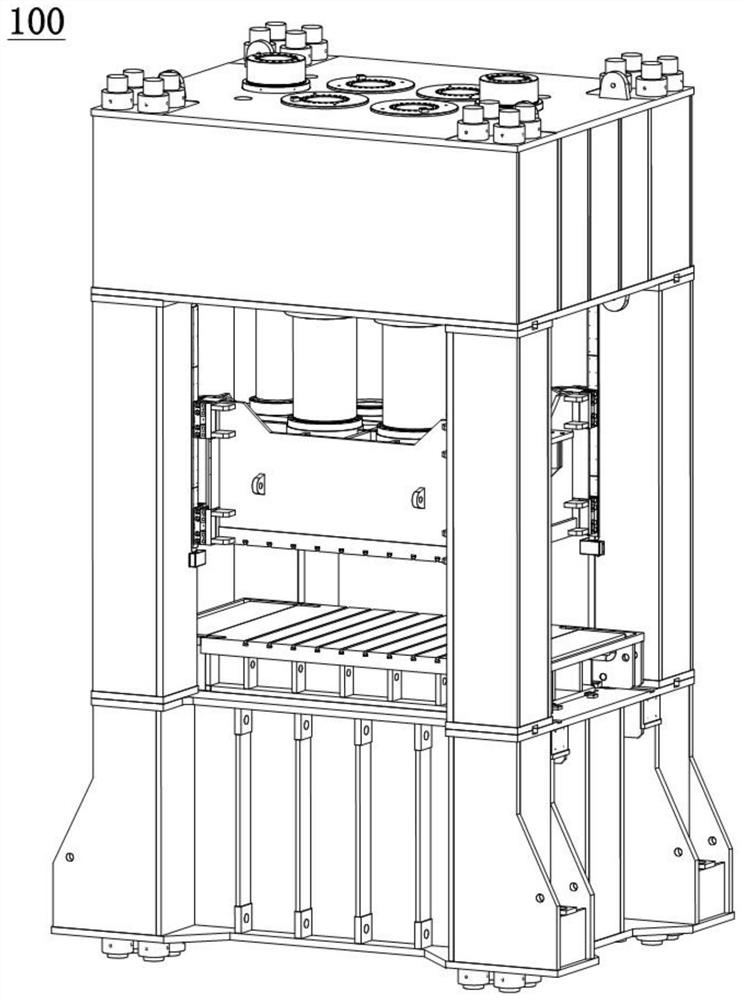

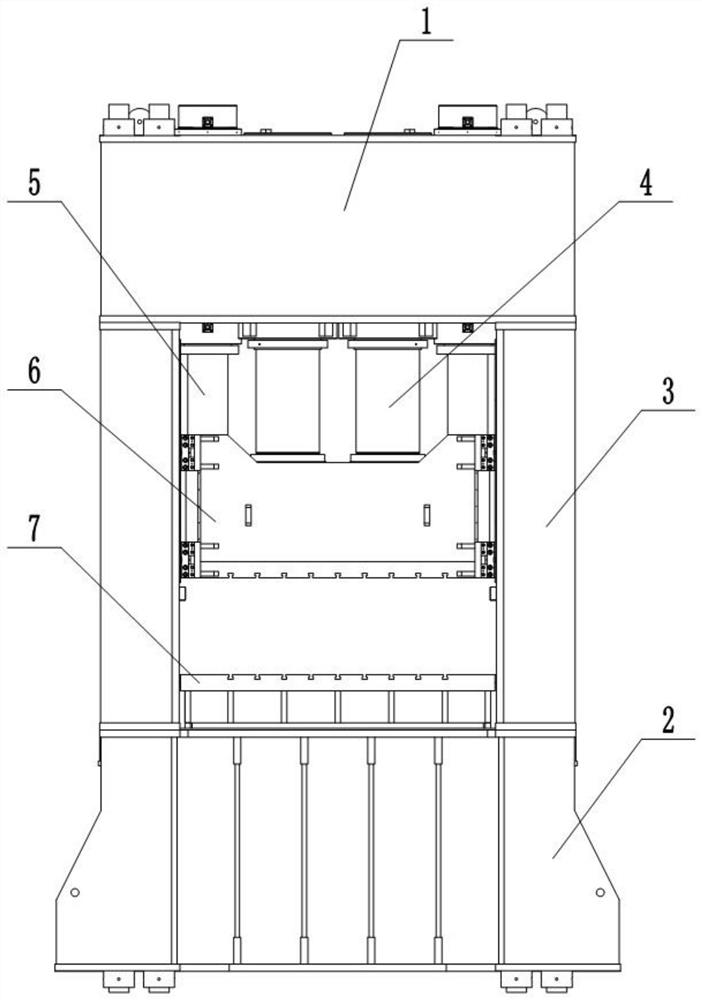

Die closing press applied to forming and production of internal high pressure and internal high pressure forming process

A technology of internal high pressure forming and molding press, which is applied in the field of pipe forming and manufacturing. It can solve the problems that the clamping press cannot meet the requirements, and achieve the effect of solving the problem of unbalanced loading, reducing mold deformation, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

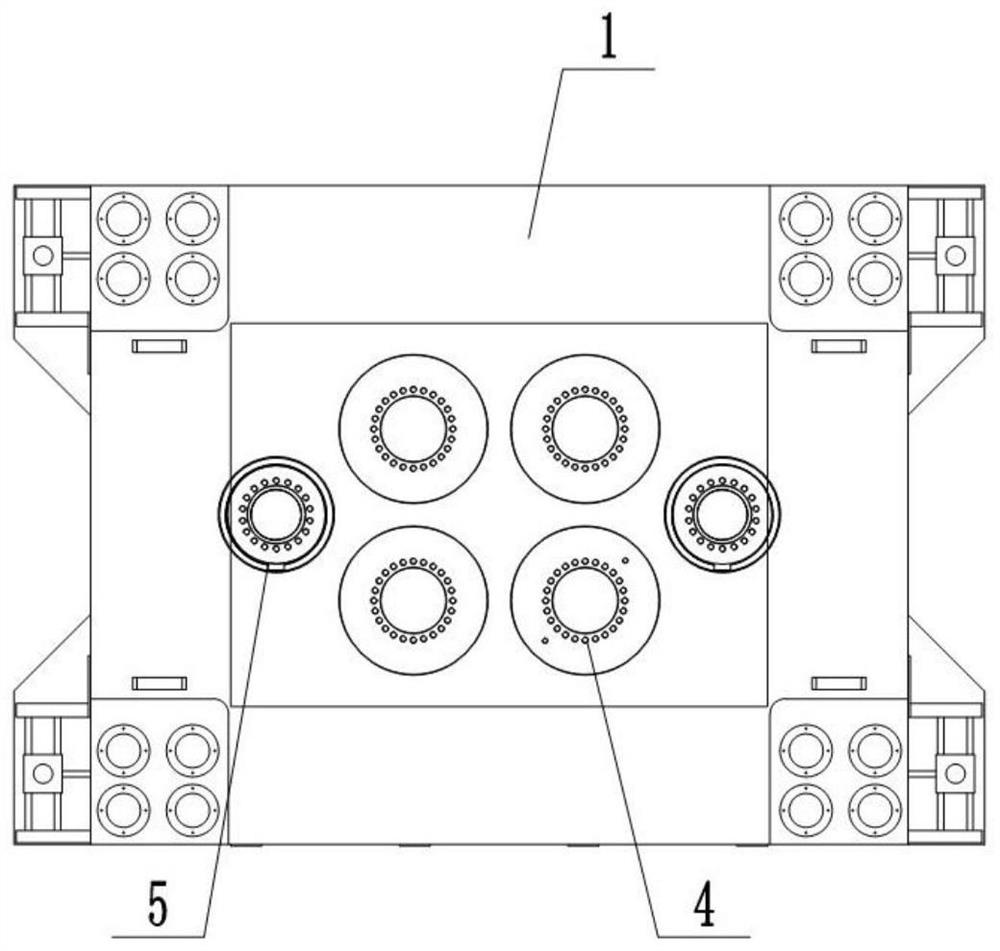

[0099] This embodiment takes the production of double U-shaped pipe parts as an example to illustrate the clamping force control strategy of the embodiment:

[0100] Such as Figure 11 As shown, one tube blank corresponds to the first area 10 and the second area 11, and the other tube blank corresponds to the third area 12 and the fourth area 13, and the center line of the projection of each cavity group is Figure 11 The boundary line between the first area 10 and the second area 11 in the center.

[0101] In this embodiment, the projected area of a tube blank in the first area 10 is S 1 , the projected area of a tube blank in the second area 11 is S 2 , the internal pressure of a tube blank is P Z1 ; The projected area of another tube blank in the third area 12 is S 3 , the projected area of another tube blank in the fourth area 13 is S 4 , another tube blank forming internal pressure is P Z2 ,

[0102] Mold opening force T generated by tube blank forming in e...

Embodiment 3

[0118] The present invention also provides an internal high pressure forming process of the clamping press 100 suitable for internal high pressure forming production using the first embodiment or the second embodiment, including the following steps:

[0119] S1: Mold closing stage: The side cylinder 5 is controlled by the second control valve 22, so that the slider 6 drives the mold 8 to close the mold. When the mold 8 is closed, the initial mold clamping force is applied through the side cylinder 5. The control valve 14 controls each master cylinder 4 to be in an unloading state;

[0120] S2: Filling stage: Fill fluid into the tube blank, the side cylinder 5 keeps loading the initial mold clamping force, and each main cylinder 4 keeps unloading state;

[0121] S3: Forming stage: the side cylinder 5 keeps loading the initial mold clamping force, and performs closed-loop control loading on each master cylinder 4 according to the mold clamping force set value through the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com