Automatic riveting machine for packaging box production

A rivet machine and packing box technology, applied in the field of rivet machines, can solve problems such as easy tilting and offset of rivets, increased wear of rivets and conveying channels, etc., and achieve the effect of reducing wear and reducing movable space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

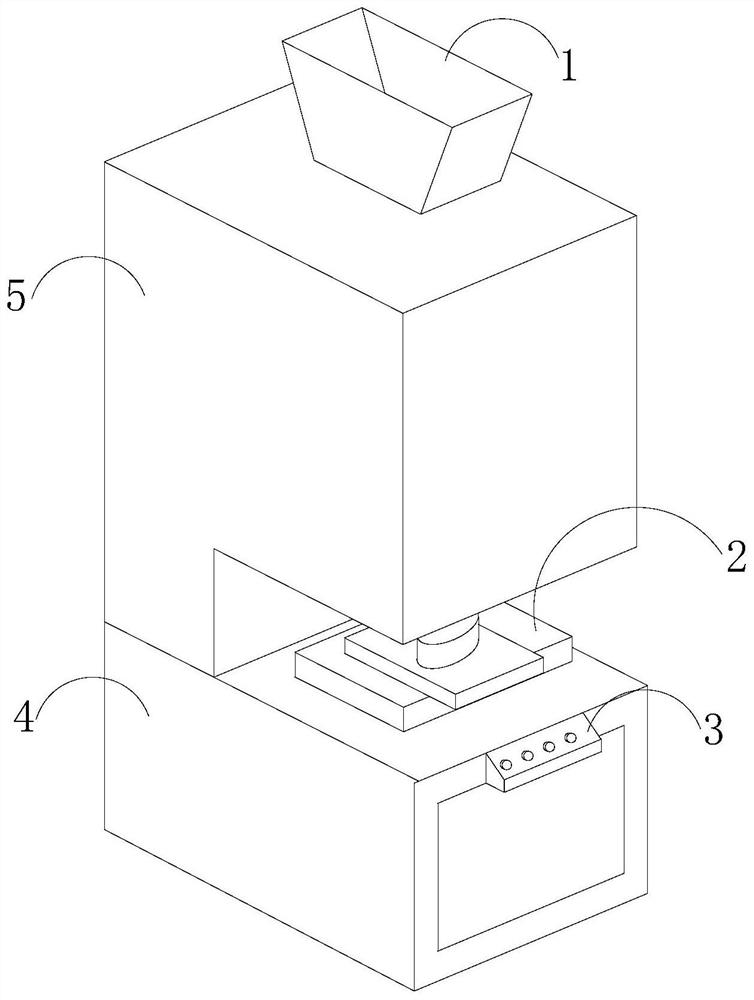

[0027] see Figure 1-Figure 5 , an automatic riveting machine for packaging box production, its structure includes a feeding box 1, a placement body 2, a control box 3, a base 4, and a processor 5, and the feeding box 1 is installed on the processor 5, and the The processor 5 is fixedly connected with the feeding box 1, the control box 3 is located on the base 4, the base 4 is flexibly connected with the control box 3, the base 4 is provided with a placement body 2, and the placement body 2 is connected with the control box 3. Base 4 clearance fit;

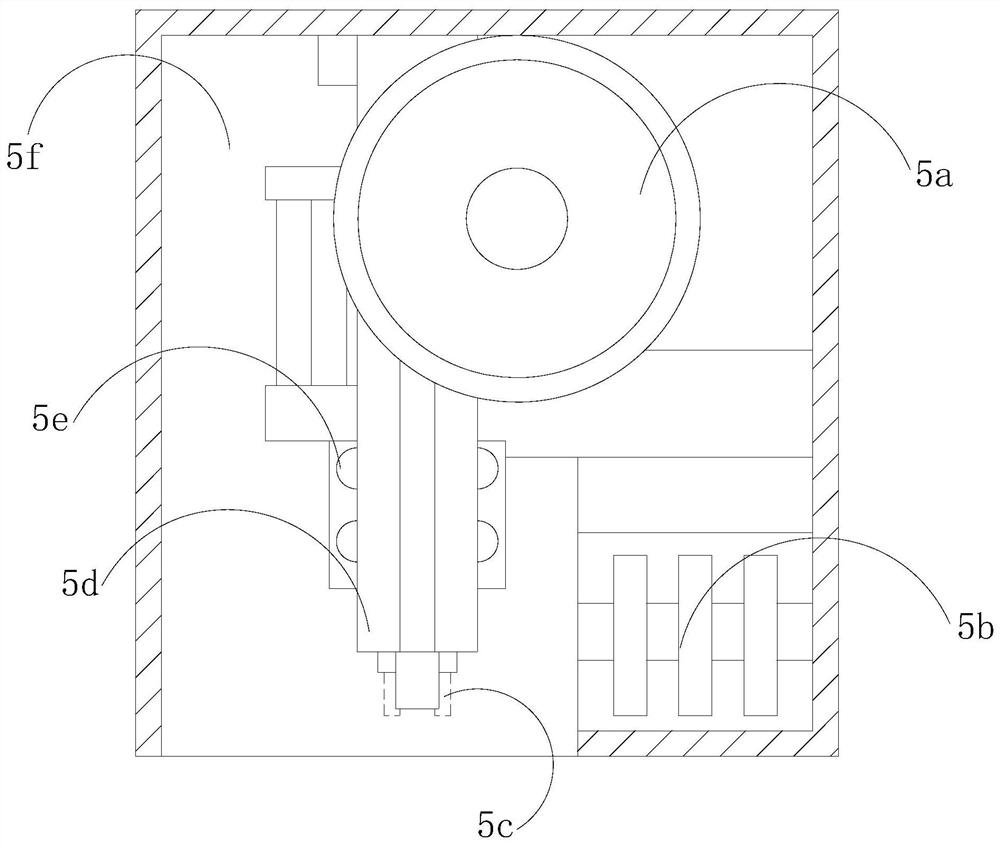

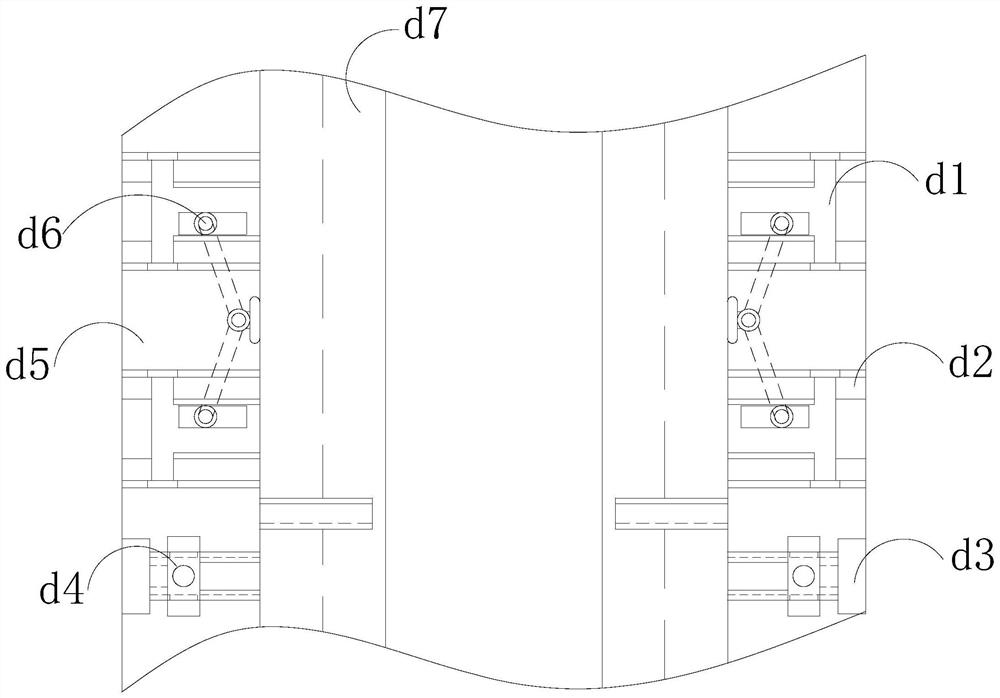

[0028] The processor 5 is provided with a dial 5a, a cooling box 5b, a feed shaft 5c, a conveyor 5d, a riveting body 5e, and a casing 5f, and the inside of the casing 5f is provided with a dial 5a, and the dial The material tray 5a is fitted with the box body 5f, and a conveyor 5d is installed on the dial 5a, and the transmitter 5d is movably connected with the dial 5a, and a riveting body 5e is provided inside the box body 5f. ...

Embodiment 2

[0036] see Figure 1-Figure 6 , an automatic riveting machine for packaging box production, its structure includes a feeding box 1, a placement body 2, a control box 3, a base 4, and a processor 5, and the feeding box 1 is installed on the processor 5, and the The processor 5 is fixedly connected with the feeding box 1, the control box 3 is located on the base 4, the base 4 is flexibly connected with the control box 3, the base 4 is provided with a placement body 2, and the placement body 2 is connected with the control box 3. Base 4 clearance fit;

[0037] The processor 5 is provided with a dial 5a, a cooling box 5b, a feed shaft 5c, a conveyor 5d, a riveting body 5e, and a casing 5f, and the inside of the casing 5f is provided with a dial 5a, and the dial The material tray 5a is fitted with the box body 5f, and a conveyor 5d is installed on the dial 5a, and the transmitter 5d is movably connected with the dial 5a, and a riveting body 5e is provided inside the box body 5f. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com