Integrally-formed composite cabin capable of conducting electromagnetic shielding and forming process of integrally-formed composite cabin

A composite material and electromagnetic shielding technology, which is applied in the field of composite material cabins, can solve the problems of long cycle, inability to electromagnetic shielding of cabins, and difficult metal processing of thin-walled structures, so as to reduce weight, solve difficult processing, and improve rigidity. and strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

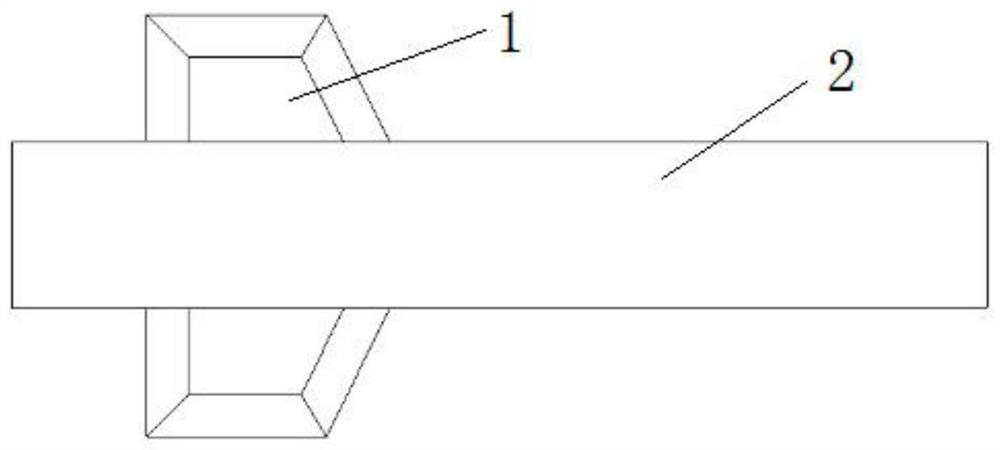

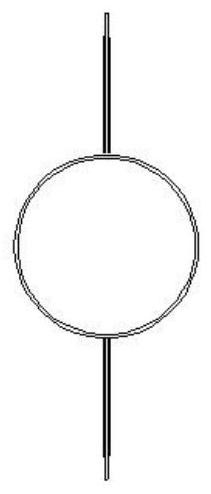

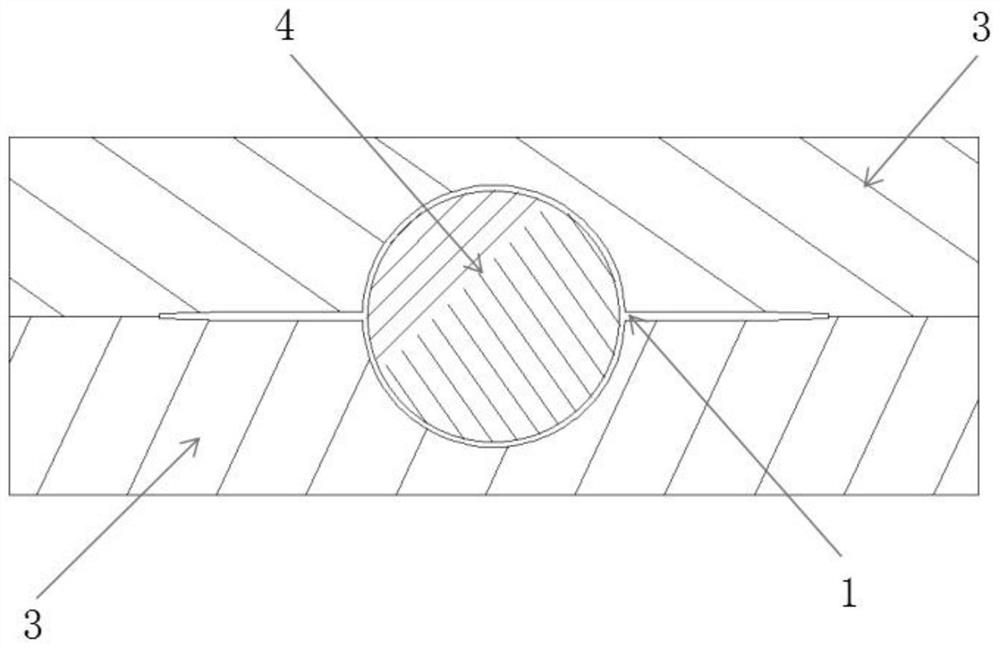

[0036] Specific implementation mode one: see Figure 1-4 This embodiment will be described. The integrally formed composite material cabin body capable of electromagnetic shielding described in this embodiment includes several fins 1 and a cylinder body 2, and several fins 1 and cylinder body 2 are integrally formed, and the cylinder body 2 includes a composite material structure layer 5. The electromagnetic shielding functional layer 6 and the inner layer 7 of the composite material structural layer, the composite material structural layer 5 encloses the electromagnetic shielding functional layer 6 , and the electromagnetic shielding functional layer 6 encloses the inner layer 7 of the composite material structural layer.

[0037] The composite material structure layer 5 has a thickness of 1mm-4mm. The thickness of the electromagnetic shielding functional layer 6 is 0.2mm-1mm. The thickness of the fins is 2mm-6mm, which is a plate structure.

[0038] The invention creates ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com