Cylindrical lithium ion battery transferring and clamping device and battery transferring and clamping method

A lithium-ion battery, transfer clip technology, applied in secondary batteries, transportation and packaging, non-aqueous electrolyte batteries, etc. The effect of improving the transfer efficiency, realizing the tightening effect, and improving the gripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples are intended to be illustrative, not to limit the scope of the invention.

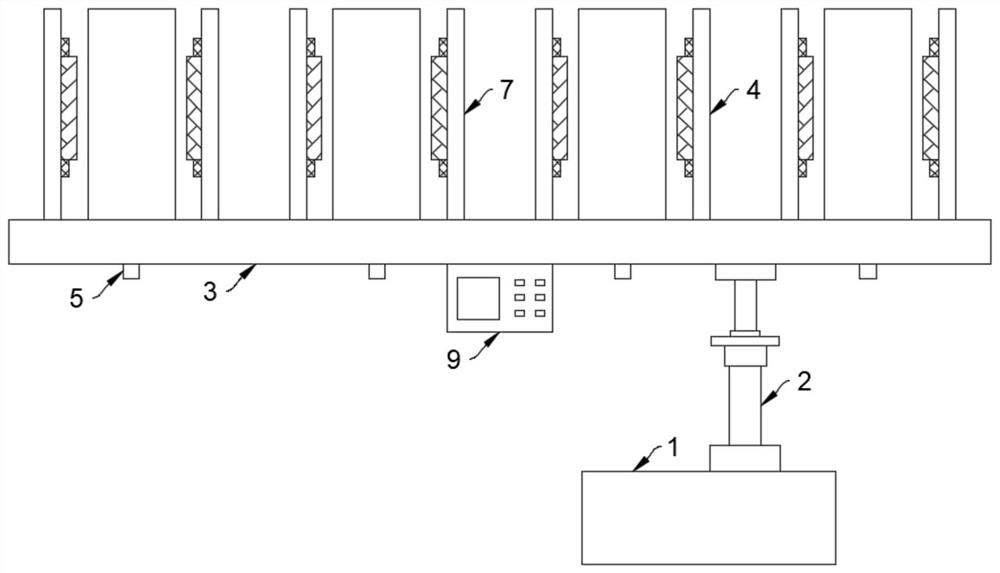

[0032] Such as Figure 1-6 As shown, a cylindrical lithium ion battery transport clamping device includes a support 1, a support 1 rotates a cylinder 2, and the cylinder 2 is fixed from one end of the support 1 fixed to the transfer plate 3, which needs to be explained. The seat 1 is symmetrically provided with a row-in wheel, and the mobile operation of the device is used, and the cylinder 2 is a single-axis cylinder of SDA75 * 240, and the cylinder 2 facilitates the lifting operation during the devices.

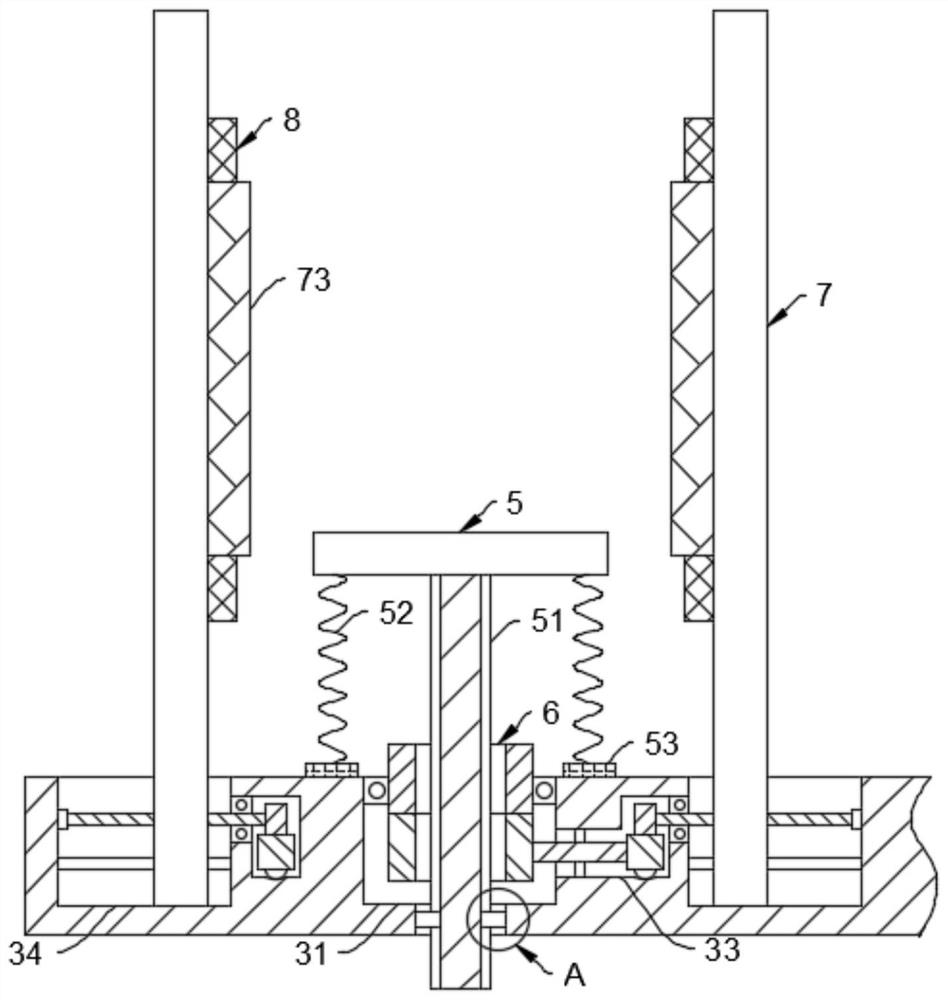

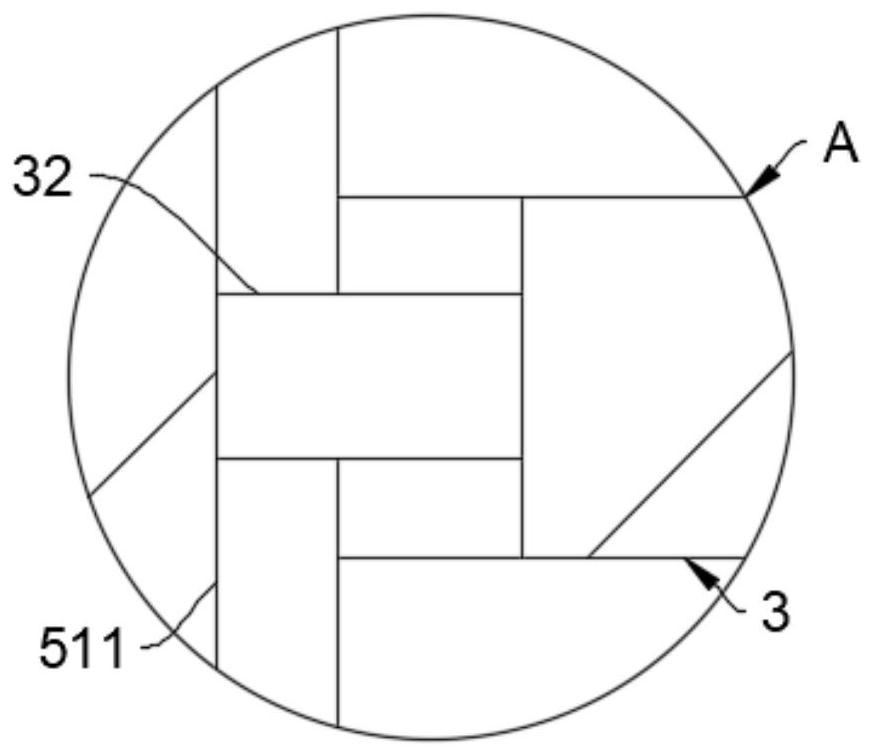

[0033] The transfer plate 3 is connected to a multi-set clamp assembly 4, and the clamp assembly 4 includes a pressure plate 5, the transmission mechanism 6, and the splint 7, the pressure plate 5 and the transfer plate 3 slide. It should be noted that the transfer plate 3 is provided with multiple sets of rotation. The groove 31, the transmission mechanism 6 rotates through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com