Construction method of platform wall and platform wall

A construction method and platform wall technology, which is applied in the field of platform walls, can solve the problems of unreasonable segmentation and low precision of formwork installation, and achieve the effect of preventing cracking and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

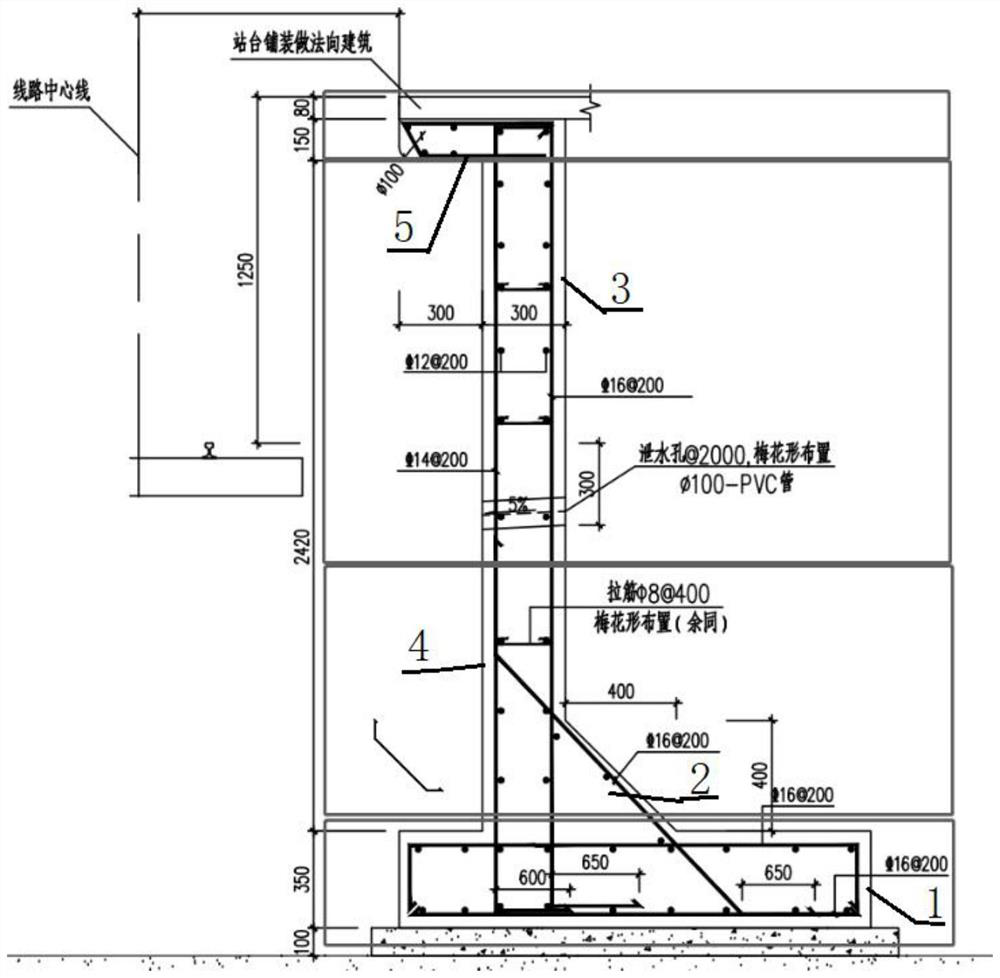

[0040] Such as Figure 1-7 As shown, the steel skeleton of the base plate 1 is bound first, and then the base plate 1 is poured with formwork. The width of the base plate 1 is 1700mm and the height is 350mm. When pouring along the length of the base plate 1, expansion joints should be preset. Plate, welding stopper 7 at the intersection of asphalt wood wool board and steel mold, there are two stoppers 7 at one end of the asphalt wood wool board, distributed on both sides of the end of the asphalt wood wool board close to the steel mold, and the stoppers 7 are far away from telescopic Putty and fillet one side of the seam. Block 7 is wide and is 20mm.

[0041] The exposed size of the asphalt wood wool board is too small. In order to improve the overall aesthetic effect, the two stoppers 7 can not only clamp the asphalt wood wool board, locate the position and width of the expansion joint, but also increase the exposed size of the expansion joint.

[0042] After the bottom pla...

Embodiment 2

[0048] Such as figure 1 As shown, Gu'an East Station has four platforms and eight lines, platforms 2 and 3 are 12.5m wide, and both sides are concrete platform walls; platforms 1 and 4 are 9.5m wide, with concrete platform walls on one side and the front of the station on the other Unit has finished vertical retaining wall. There are two types of Gu’an East platform walls. The walls near the main line of platforms 2 and 3 have been constructed on site. The total height of the platform wall structure is 3m, and it is composed of a bottom plate, an axil, a wall, and an overhanging eave. See details figure 1

[0049] The platform wall is one of the most important structures of the entire platform. Its completion quality and effect play an important role in the effect of the entire platform, so we carefully plan the entire process before starting construction:

[0050] The platform wall formwork is made of steel molds, which have the following advantages: multiple turnovers can...

Embodiment 3

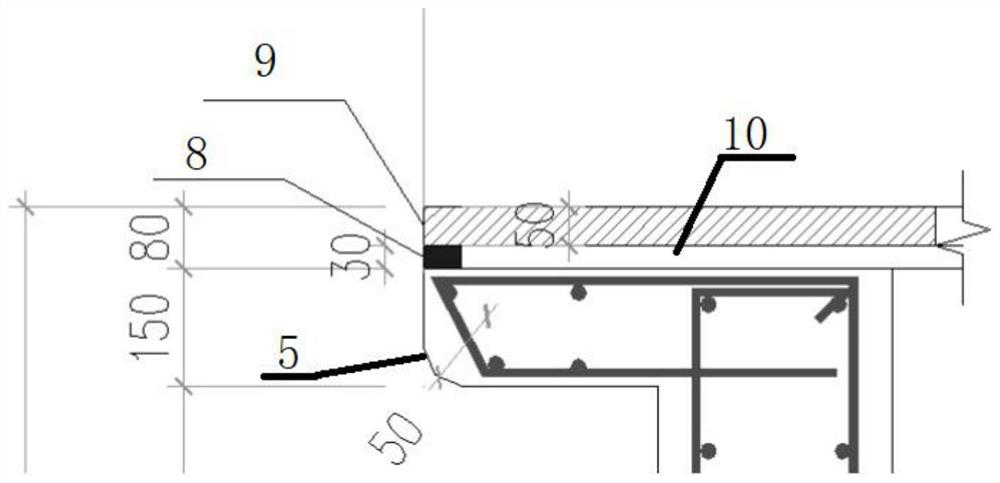

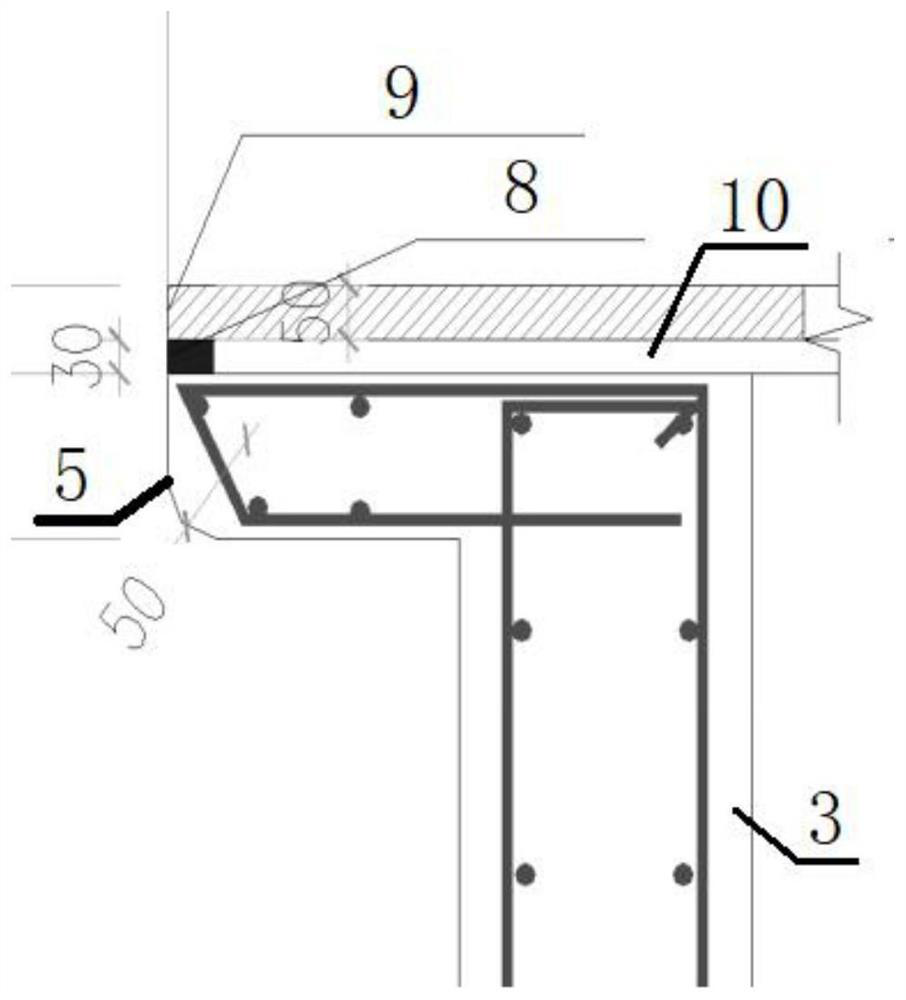

[0059] Between the concrete bar 8 and the mortar layer 10, an elastic pad 11, such as a rubber strip, is wrapped with a waterproof coiled material 12, and the elastic pad 11 is provided with vertical holes or voids along its axial direction. Cavity

[0060] The elastic pad 11 prevents the connection between the concrete bar and the mortar layer from being affected by thermal expansion and contraction, and they are squeezed to form cracks. The elastic pad 11 can play the role of a temperature joint. The elastic pad 11 is wrapped with a waterproof membrane 12. It can prevent the rainwater from soaking the elastic pad, making it aging and losing its elasticity. The holes or cavities of the elastic pad 11 can make it have greater deformation capacity and save more materials. The cavity is made of rubber spiral Ribs 13, rubber spiral ribs 13 and elastic pads can be integrally formed, and rubber spiral ribs 13 are horizontally arranged in holes or cavities, so that elastic pads 11 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com