Current sampling null drift processing method and method

A current sampling and processing method technology, which is applied in the direction of only measuring current, measuring current/voltage, and measuring electrical variables, etc., can solve problems such as reduced accuracy, limited adaptability, and submerged effective signals, so as to achieve accurate data collection and prevent safety Influence and improve the effect of control reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

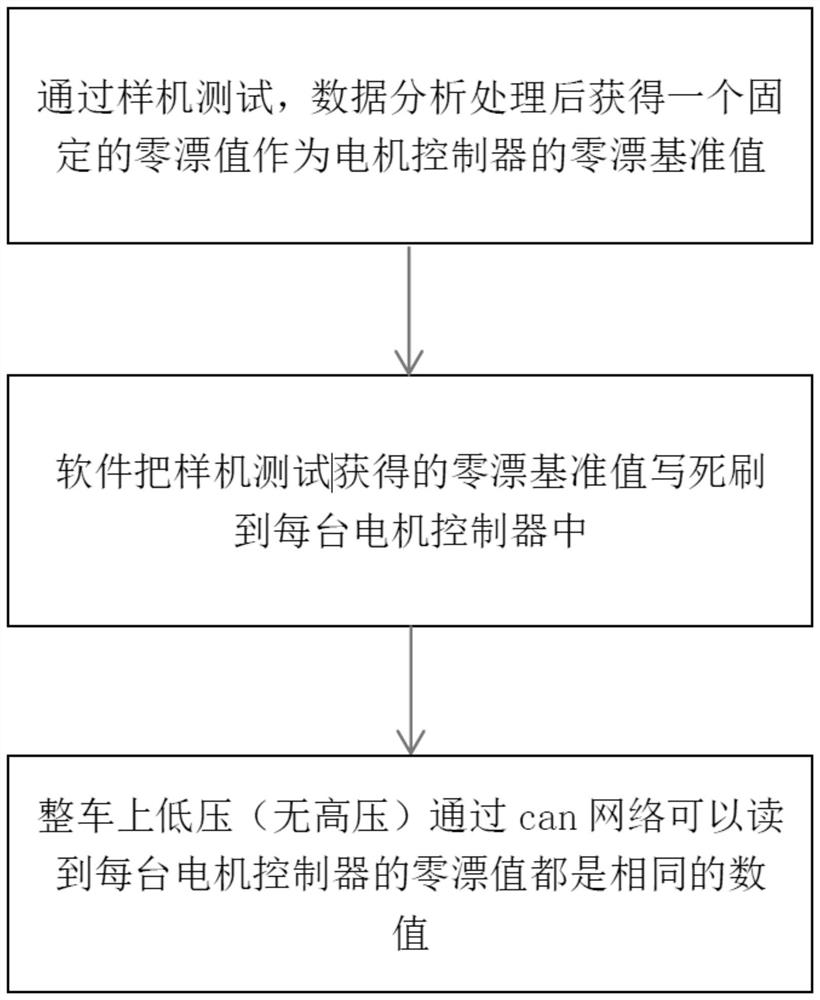

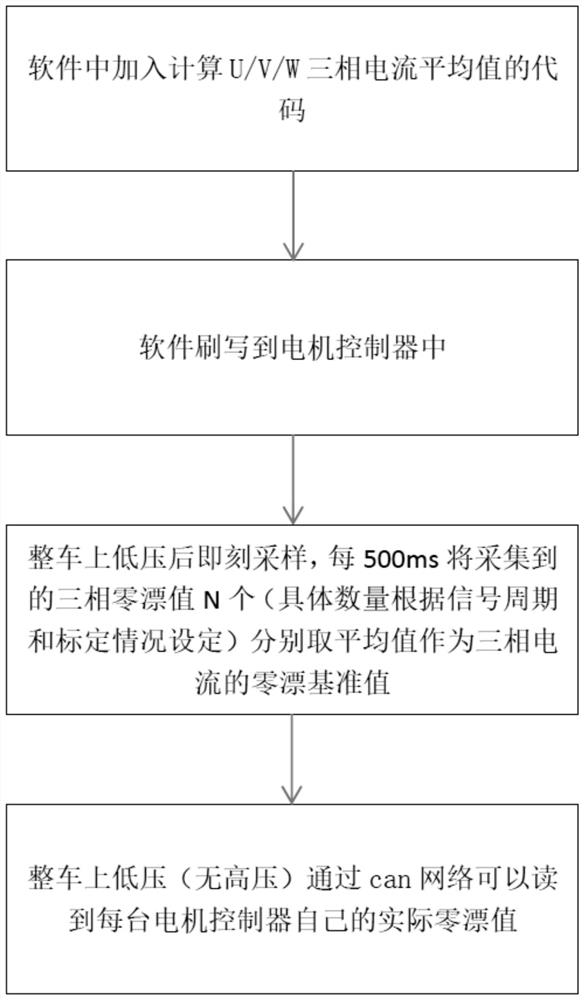

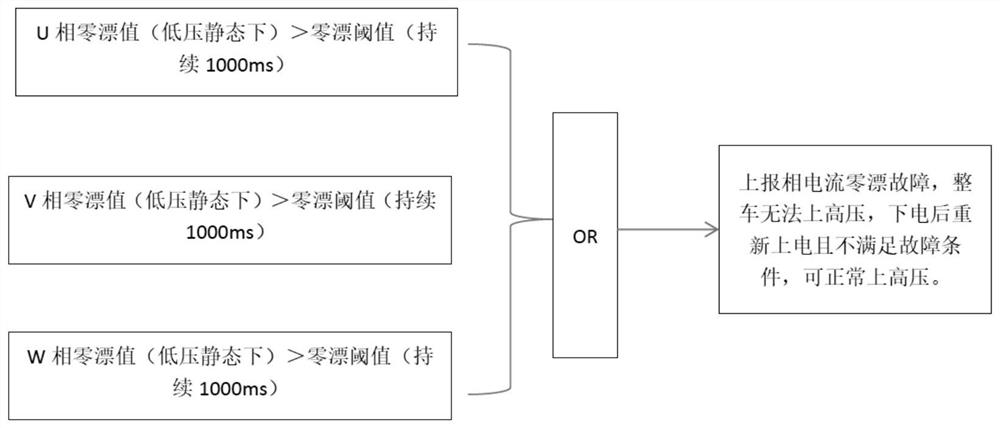

[0021] This application is mainly used in the automotive field. The automotive motor controller collects the three-phase electric current signal of the vehicle's high-voltage AC, and then realizes the control of the motor according to the current. However, the current data collected by the motor controller is generally inaccurate due to current zero drift. , which in turn leads to inaccurate and unreliable control caused by inaccurate acquisition currents. Based on this, the data collected by sensors will be processed with zero drift in the prior art, such as figure 1 As shown, the traditional zero drift calculation is to use the controller prototype to test, and then write the zero drift value in the program. However, different controllers, especially the Hall sensor used for internal curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com