Balanced design method for high-temperature creep and low-temperature relaxation performance of recycled asphalt mixture

A technology of recycled asphalt and high temperature creep, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve the problems of heavy workload, lack of comprehensive consideration, balanced design reliability and poor accuracy, etc., to achieve easy operation, Improve accuracy and feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

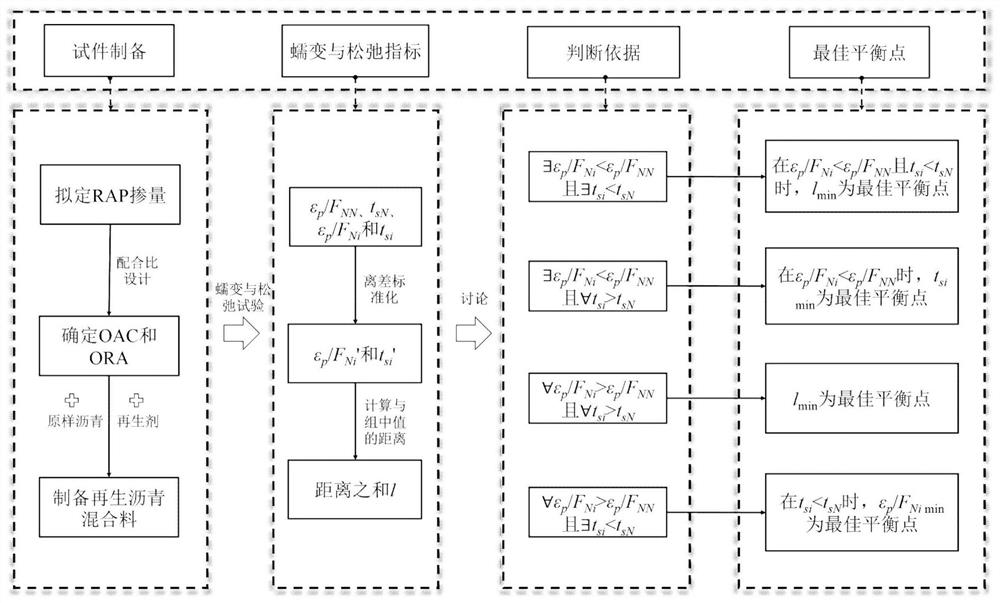

[0082] A balance design method for high-temperature creep and low-temperature relaxation properties of recycled asphalt mixture, comprising the following steps:

[0083] The first step: formulate the amount of RAP;

[0084] In this example, a recycled asphalt mixture with a content of 20% RAP is used.

[0085] Step 2: Determine initial oil-to-stone ratio (OAC) and regenerant dosage (ORA)

[0086] According to the mix design, the initial OAC and ORA were determined to be 5.13% and 4.0%, respectively.

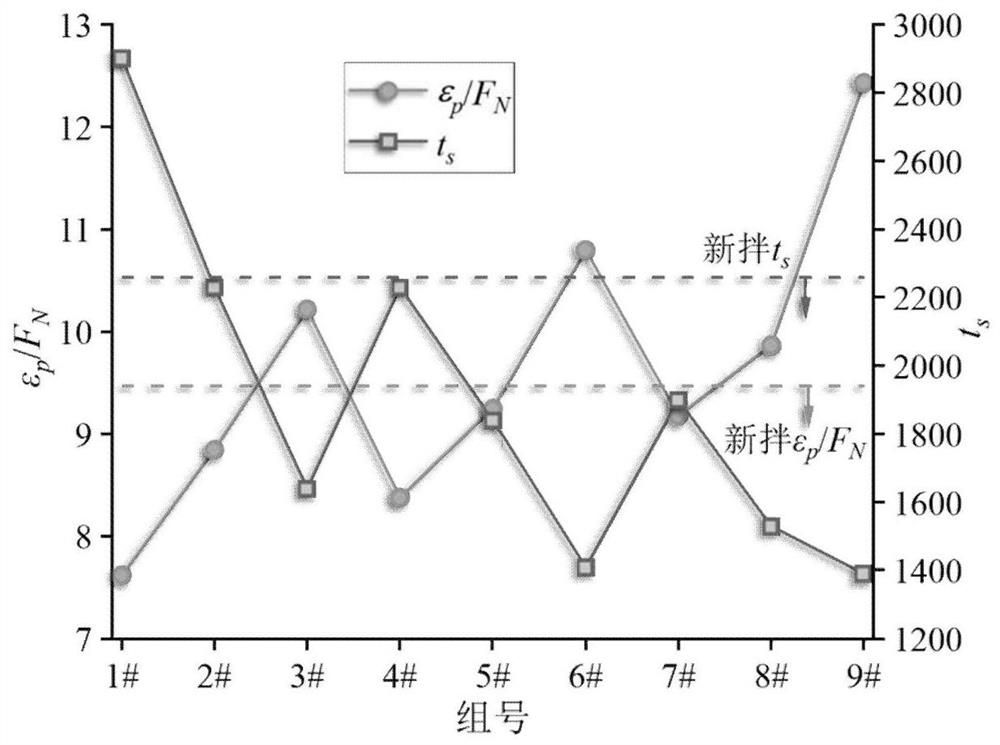

[0087] The third step: prepare n groups of different recycled asphalt mixture specimens

[0088] On the basis of OAC and ORA, referring to the actual engineering application, the ratio of oil to stone and the regenerant were increased in proportion respectively, so that they both had 3 groups of different dosages (including OAC and ORA). All levels were cross-combined and mixed into the mixture at one time, and finally 9 groups of different recycled asphalt mixtures were prepa...

Embodiment 2

[0101] A balance design method for high-temperature creep and low-temperature relaxation properties of recycled asphalt mixture, comprising the following steps:

[0102] The first step: formulate the amount of RAP;

[0103] In this example, a recycled asphalt mixture with a content of 30% RAP is used.

[0104] Step 2: Determine initial oil-to-stone ratio (OAC) and regenerant dosage (ORA)

[0105] According to the mix design, the initial OAC and ORA were determined to be 5.15% and 4.0%, respectively.

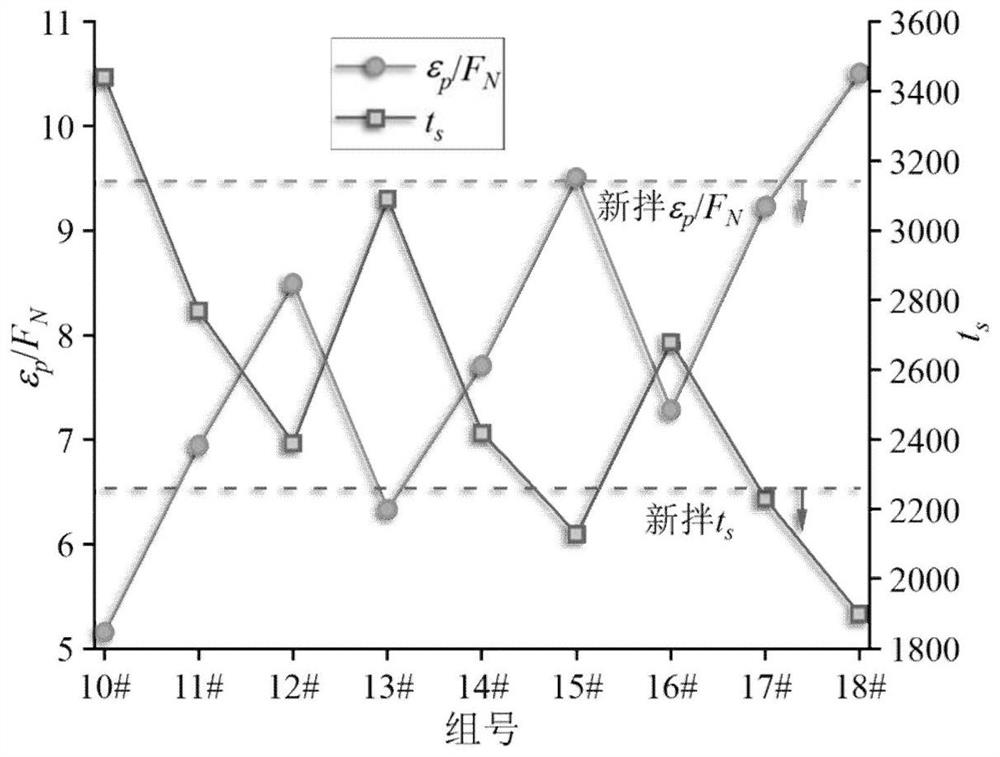

[0106] The third step: prepare n groups of different recycled asphalt mixture specimens

[0107] On the basis of OAC and ORA, referring to the actual engineering application, the ratio of oil to stone and the regenerant were increased in proportion respectively, so that they both had 3 groups of different dosages (including OAC and ORA). All levels were cross-combined and mixed into the mixture at one time, and finally 9 groups of different recycled asphalt mixtures were prepa...

Embodiment 3

[0120] A balance design method for high-temperature creep and low-temperature relaxation properties of recycled asphalt mixture, comprising the following steps:

[0121] The first step: formulate the amount of RAP;

[0122] In this example, a recycled asphalt mixture with a content of 50% RAP is used.

[0123] Step 2: Determine initial oil-to-stone ratio (OAC) and regenerant dosage (ORA)

[0124] According to the mix design, the initial OAC and ORA were determined to be 5.20% and 4.0%, respectively.

[0125] The third step: prepare n groups of different recycled asphalt mixture specimens

[0126] On the basis of OAC and ORA, referring to the actual engineering application, the ratio of oil to stone and the regenerant were increased in proportion respectively, so that they both had 3 groups of different dosages (including OAC and ORA). All levels were cross-combined and mixed into the mixture at one time, and finally 9 groups of different recycled asphalt mixtures were prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com