Flat single-shaft multi-point driving mechanism capable of passing through main beam torque pipe

A multi-point drive, torque tube technology, applied in the field of solar power generation, can solve the problems of affecting the installation progress, high construction difficulty, waste of main beams, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the patent solution of the present invention, the technical solution in the patent embodiment of the present invention will be clearly and completely described below in conjunction with the drawings in the patent embodiment of the present invention.

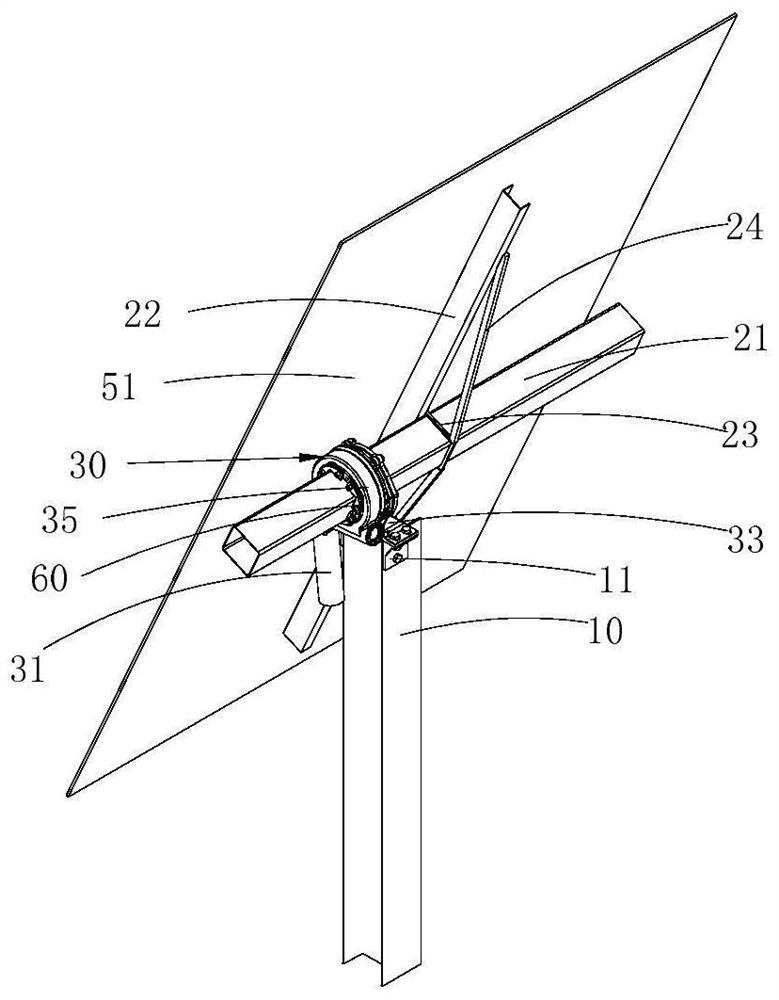

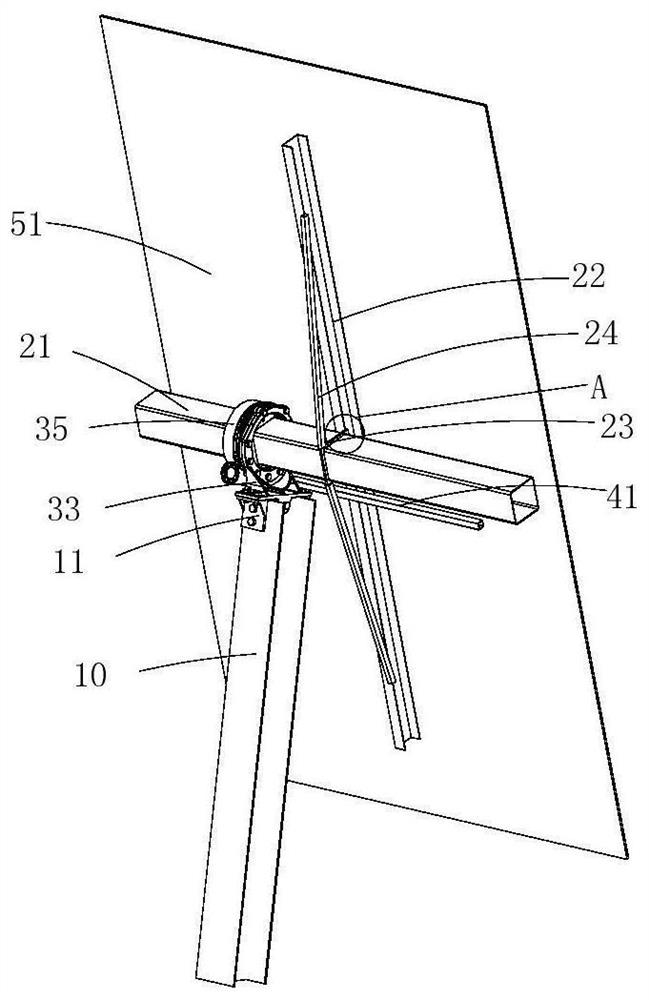

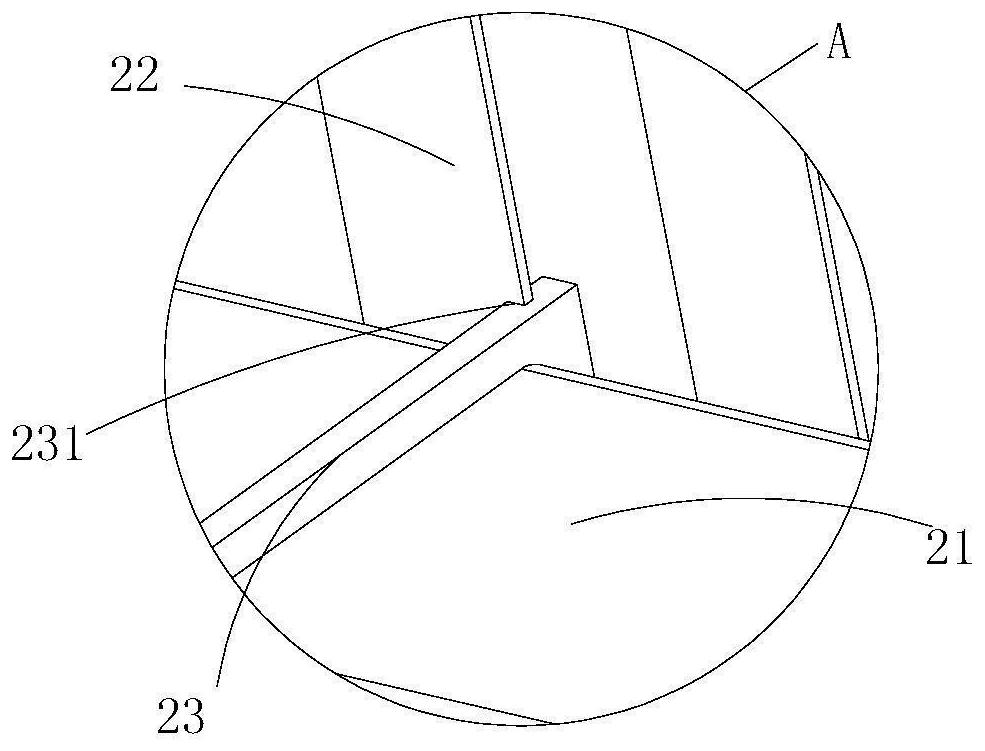

[0037] refer to figure 1 , figure 2 , a flat single-axis multi-point driving mechanism that passes through the main beam torque tube, including a column 10, a main beam 21, a rotary reducer 30 and a motor 31; the column 10 is used as a support, and the column 10 is set in an "H" shape , used to support the drive mechanism as a whole, of course, in other embodiments, the column 10 can be set as a cylindrical tube or a polygonal tube; the main beam 21 is set as a polygonal tube, and the main beam 21 is equipped with At least one solar panel 51, the number of the solar panel 51 can be arranged according to the actual working conditions, and the length of the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap