Quartz crushing and cleaning device

A cleaning device, quartz technology, applied in the direction of grain processing, etc., can solve the problems of inconvenient cleaning of quartz dust, affecting physical health, and easy damage to the crushing box, achieving the effect of strong practicability, increased service life and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

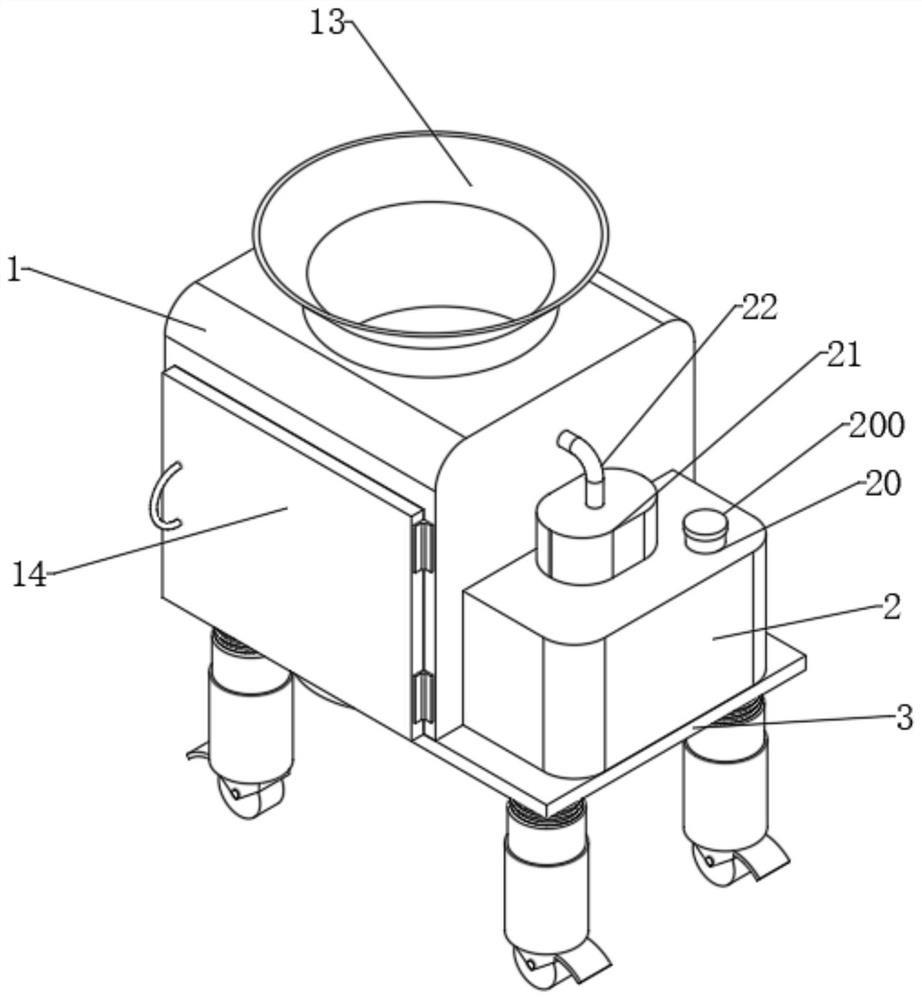

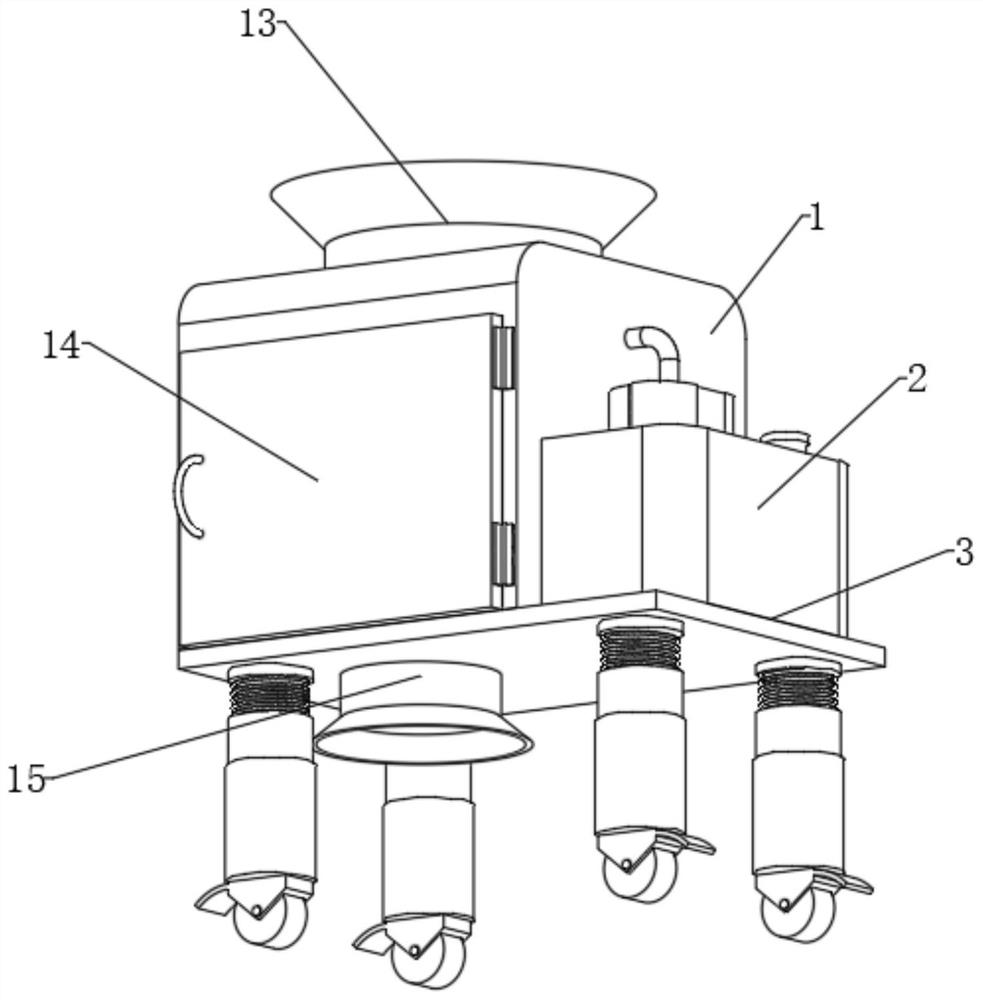

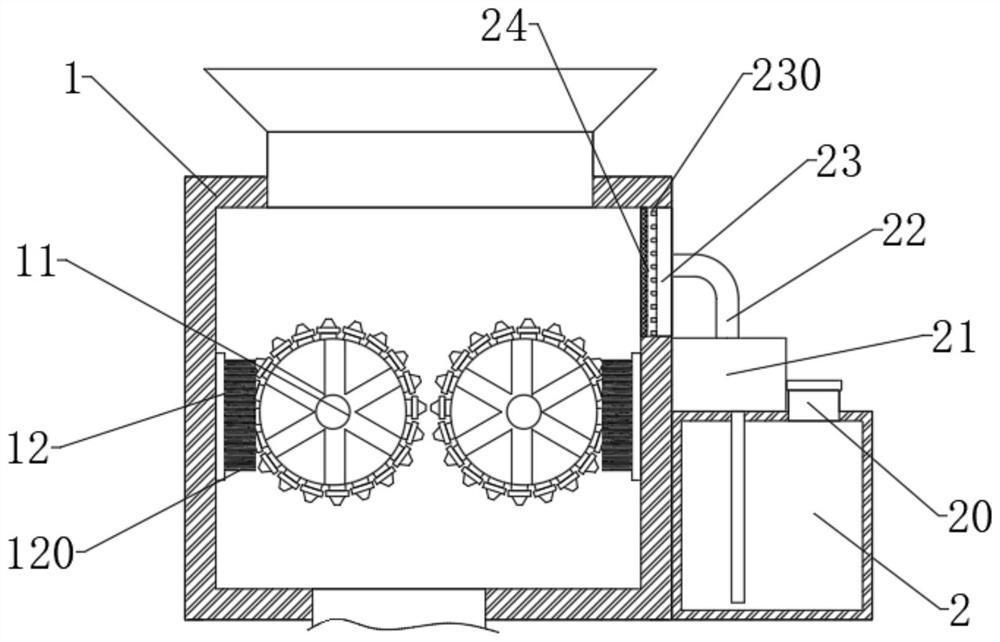

[0024] A quartz crushing and cleaning device, in order to solve the problems that the existing quartz crushing device is inconvenient to clean, the quartz dust on the surface of the crushing roller is inconvenient to clean, the dust floating in the air affects the health of the body, and the crushing box is easily damaged. A preferred embodiment, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the crushing box 1 is included, the bottom of the crushing box 1 is provided with a base 3, the base 3 includes a bottom plate 31, the bottom of the bottom plate 31 is provided with a spring seat 32 near the four corners, and the bottom of the spring seat 32 is provided with an electric telescopic leg 33, the electric telescopic leg 33 is an electric telescopic leg of a JINGE model, which can be stretched and retracted by the piston rod of the electric telescopic leg 33, and adjusted to a suitable height for the work of the crushing box 1, which is more practical. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com