Apparatus for generating hot air using waste animal fat generated by heating waste of slaughtered pigs or cattle

A production device and animal fat technology, which is applied in the production of fat oil/fat, the recovery of fat oil/fatty acid from waste, and the generation of fat, etc., can solve the problems of public health threats and environmental pollution, and achieve the effect of reducing degreasing cost and facilitating storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

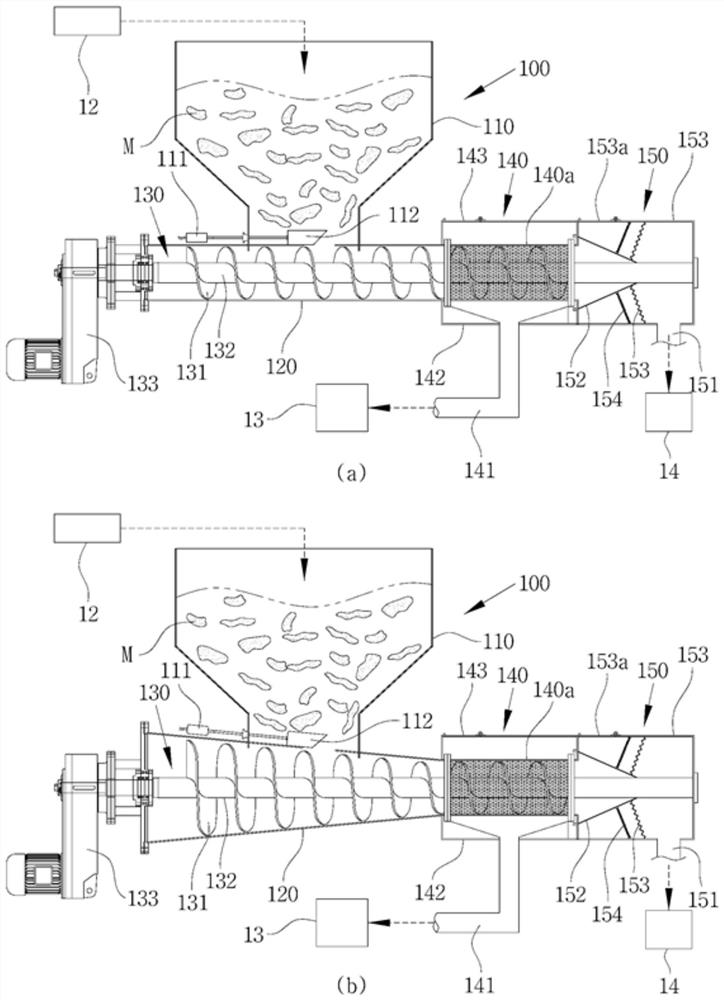

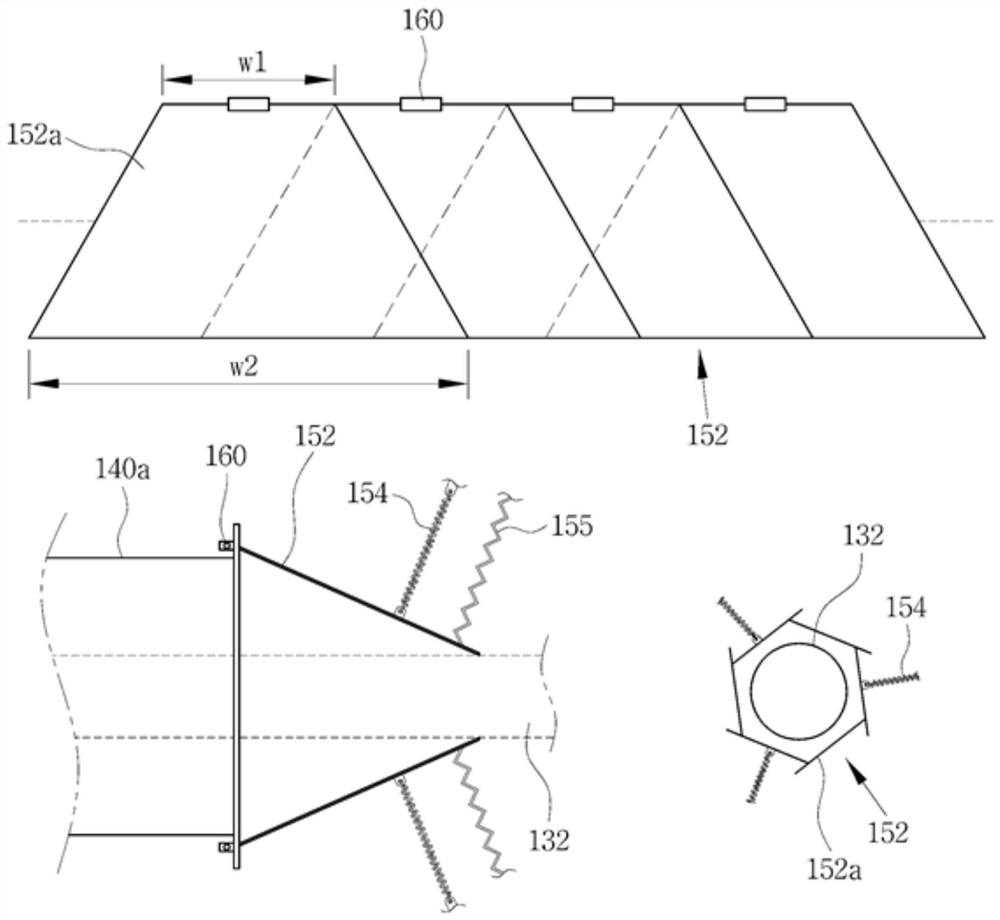

[0054] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. The explanations are for the convenience of those skilled in the art with common knowledge.

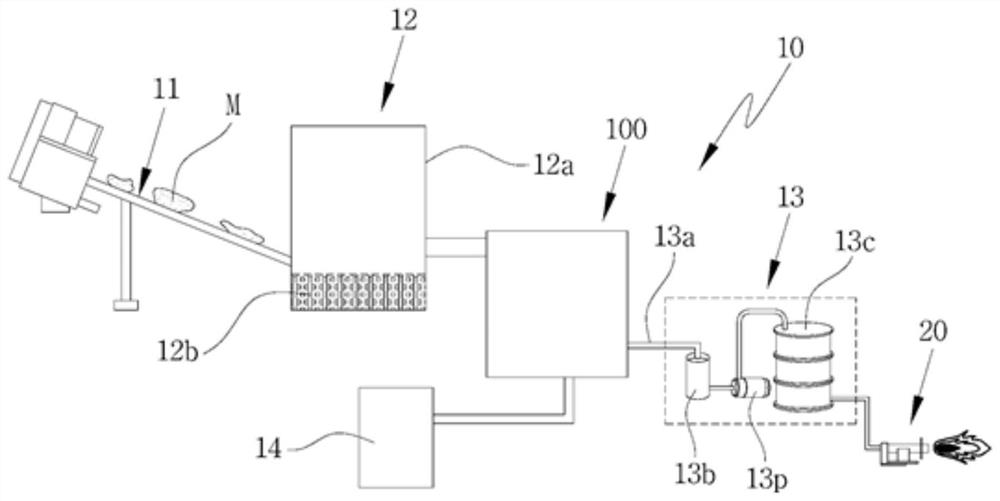

[0055] Such as Figure 1 to Figure 8 Shown, according to a kind of hot air generating device 10 utilizing discarded tallow of the present invention, comprise:

[0056] Conveyor belt conveying unit 11, which is used to convey slaughtered waste such as cattle or pigs;

[0057] a heating unit 12 for heating at high temperature the slaughtered waste conveyed by said conveyor conveying unit 11;

[0058] The degreasing unit 100 is used to store the slaughtered waste heated by the heating unit 12, and separate it into waste fat and slaughter by-products before discharging;

[0059] Grease storage unit 13, which is connected to the degreasing unit 100 and used to store the waste grease generated by the degreasing unit 100;

[0060] a drying unit 14, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com