Road finisher with compression control

A paver and road technology, applied in the direction of roads, roads, road repair, etc., can solve problems such as difficulty in controlling the change of paving height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

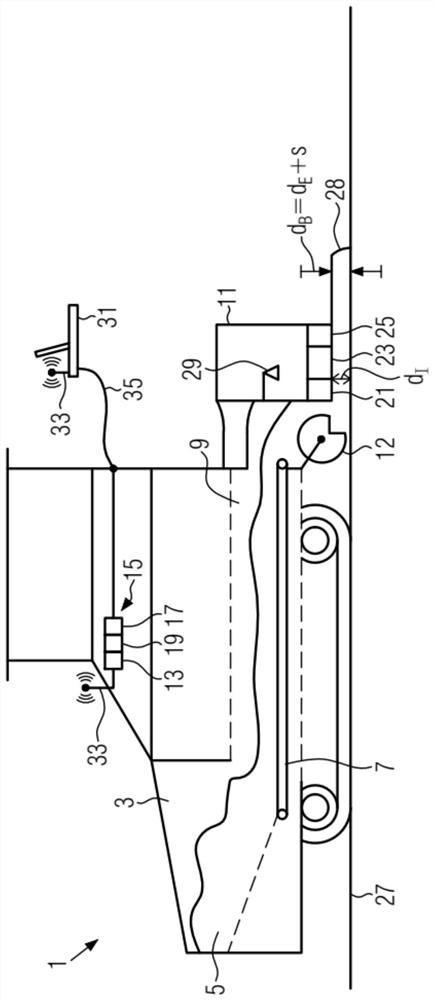

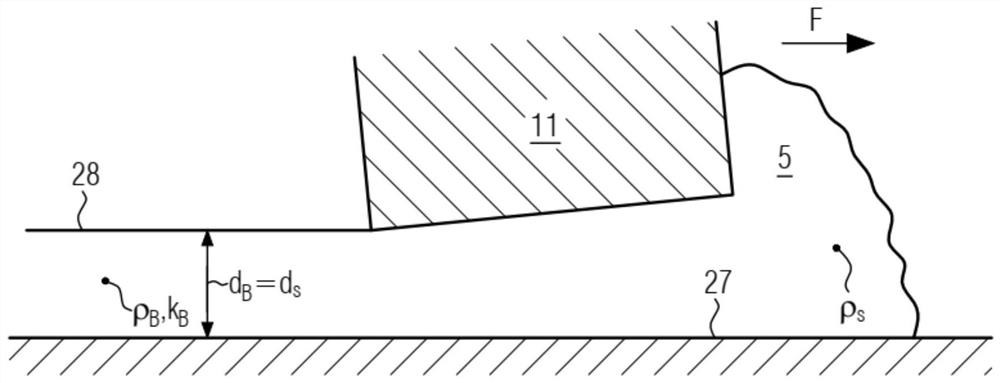

[0034] figure 1A schematic side view of a road paver 1 is shown, wherein in the lower area of the sectional view a hopper 3 with paving material 5 is shown, and the paving material 5 is transported by a material conveyor 7 via a pipe 9 at the rear position in front of the flat plate 11 and evenly distributed there by the screw conveyor 12 . The road paver 1 also comprises a GNSS receiver 13 connected to an electronic control system 15 . The electronic control system 15 includes a memory 17 and a data processor 19 . The paving screed 11 comprises a tamper 21 , a screed 23 and a pressing bar 25 , wherein there may also be a plurality of these components. The paving material 5 is pre-compacted with the paving screed 11 and spread on the subgrade 27 as having a layer thickness d B The pavement 28, in ideal operation, layer thickness d B Equivalent to target layer thickness d S , where the target layer thickness d S d thicker than the desired final layer E Higher one rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com