A self-cleaning evaporator based on microgrid and its application method

A self-cleaning and evaporator technology, applied in the field of micro-grid, can solve problems such as easy dust accumulation, inconvenient cleaning, and lower heat exchange rate, so as to prevent dust accumulation, avoid heat exchange rate, and improve heat exchange rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

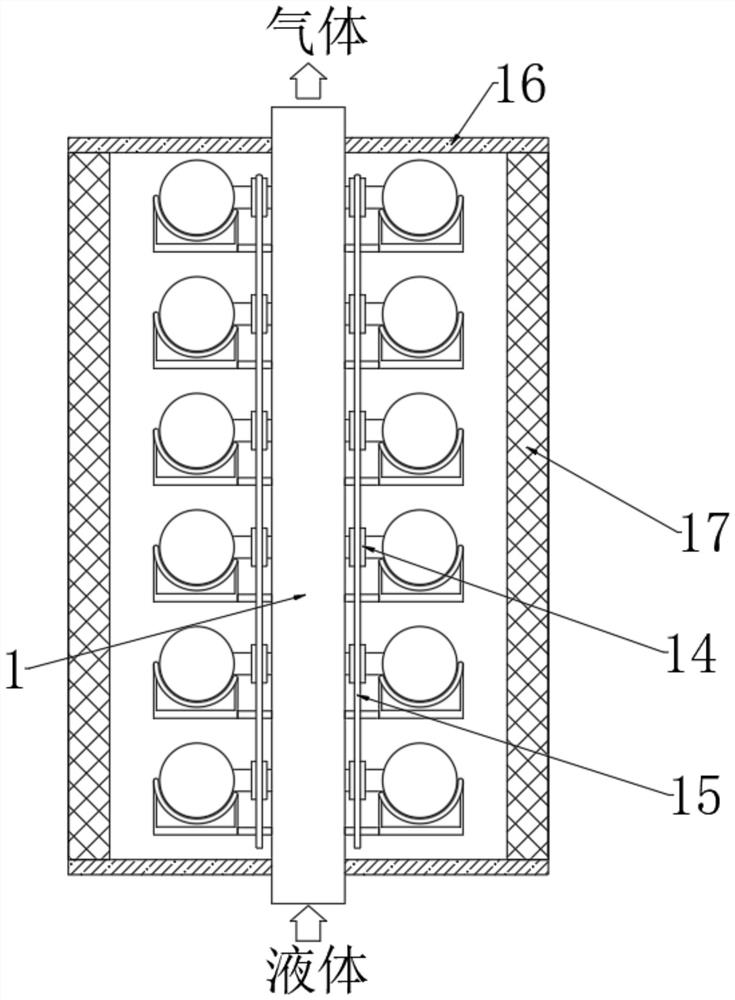

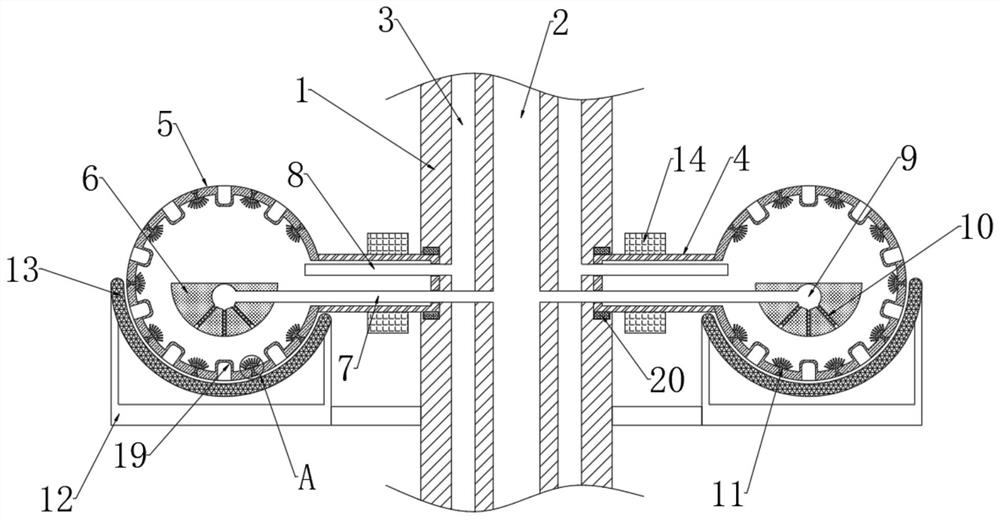

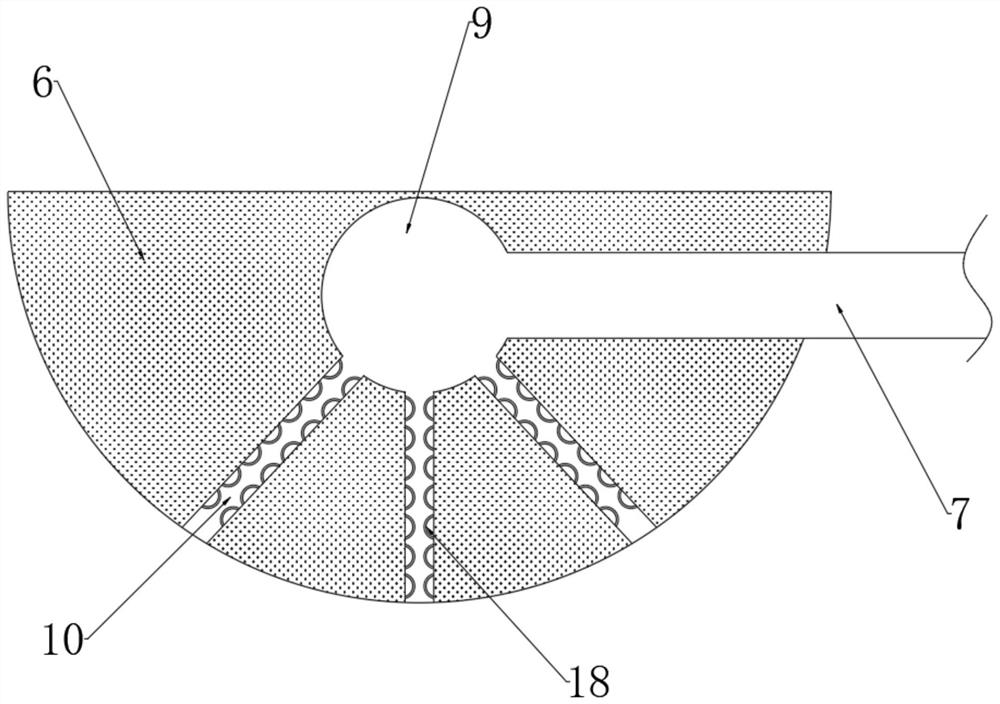

[0045] see Figure 1-5 , a self-cleaning evaporator based on a microgrid, including a gas-liquid duct 1, see Figure 1-3 , the inner wall of the middle part of the gas-liquid pipe 1 is provided with a liquid pipe 2, the outer cover of the gas-liquid pipe 1 is provided with a transparent protective frame 16, and both sides of the transparent protective frame 16 are fixedly connected with a large particle dust filter screen 17, The large particle dust filter screen 17 pre-filters the large particle impurities in the air to reduce the dust removal pressure of the ash removal plate 13. The inner wall of the gas-liquid communication pipe 1 is provided with two ventilation pipes 3, and the two ventilation pipes 3 are respectively Located on both sides of the liquid pipe 2, the side walls on both sides of the gas-liquid pipe 1 are rotatably connected with a plurality of rotating pipes 4 arranged at equal intervals, and the side walls of the gas-liquid pipe 1 are rotatably connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com