Precision seeder for corn breeding test

A corn breeding and seeder technology, applied in the field of agricultural machinery, can solve the problems that affect the authenticity and scientificity of corn breeding test results, reduce the accuracy and efficiency of corn breeding field tests, and are diverse and error-prone in sowing forms and methods, and avoid problems such as Uneven or hollow sowing, high degree of automation, guaranteeing the effect of plant spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

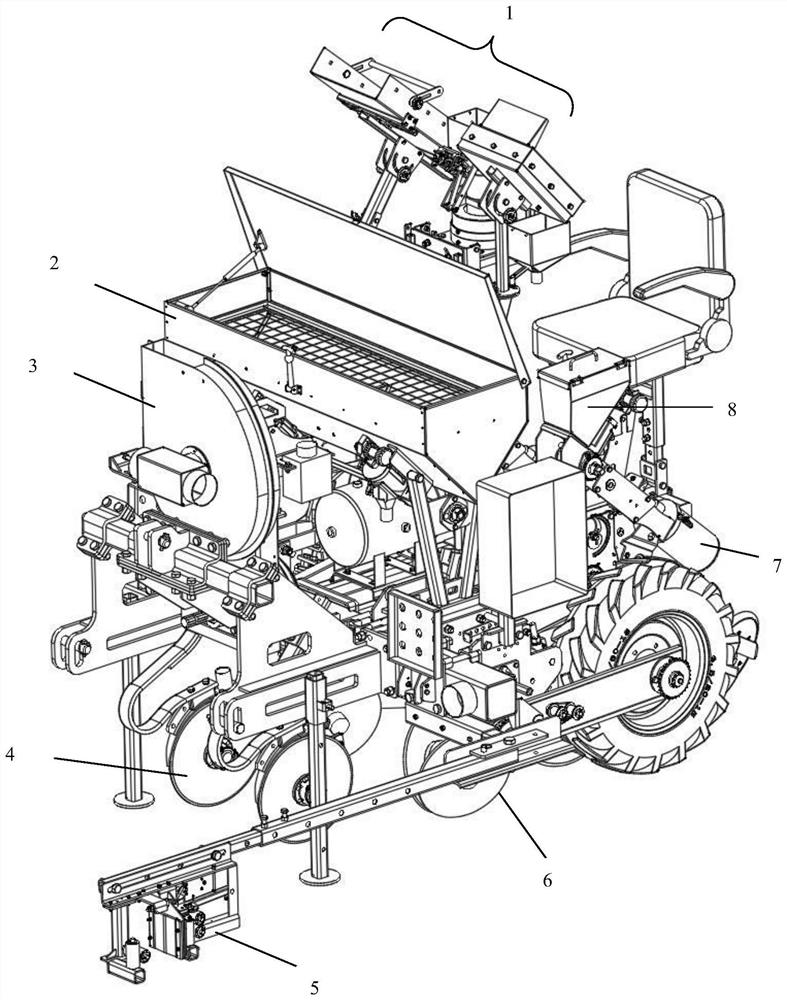

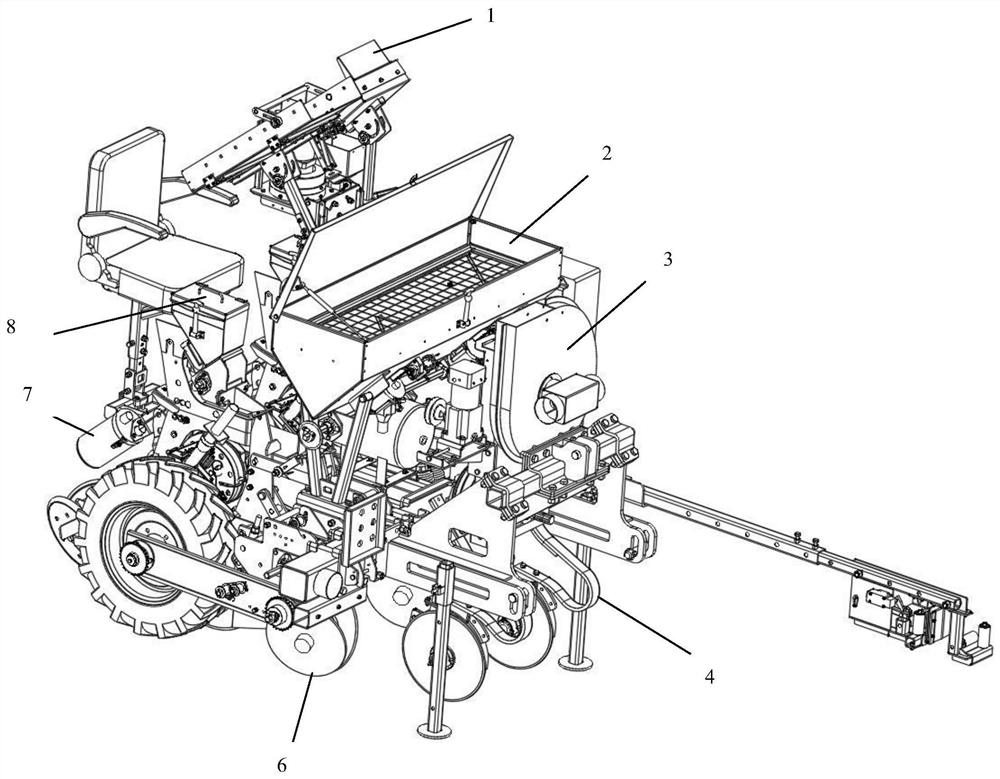

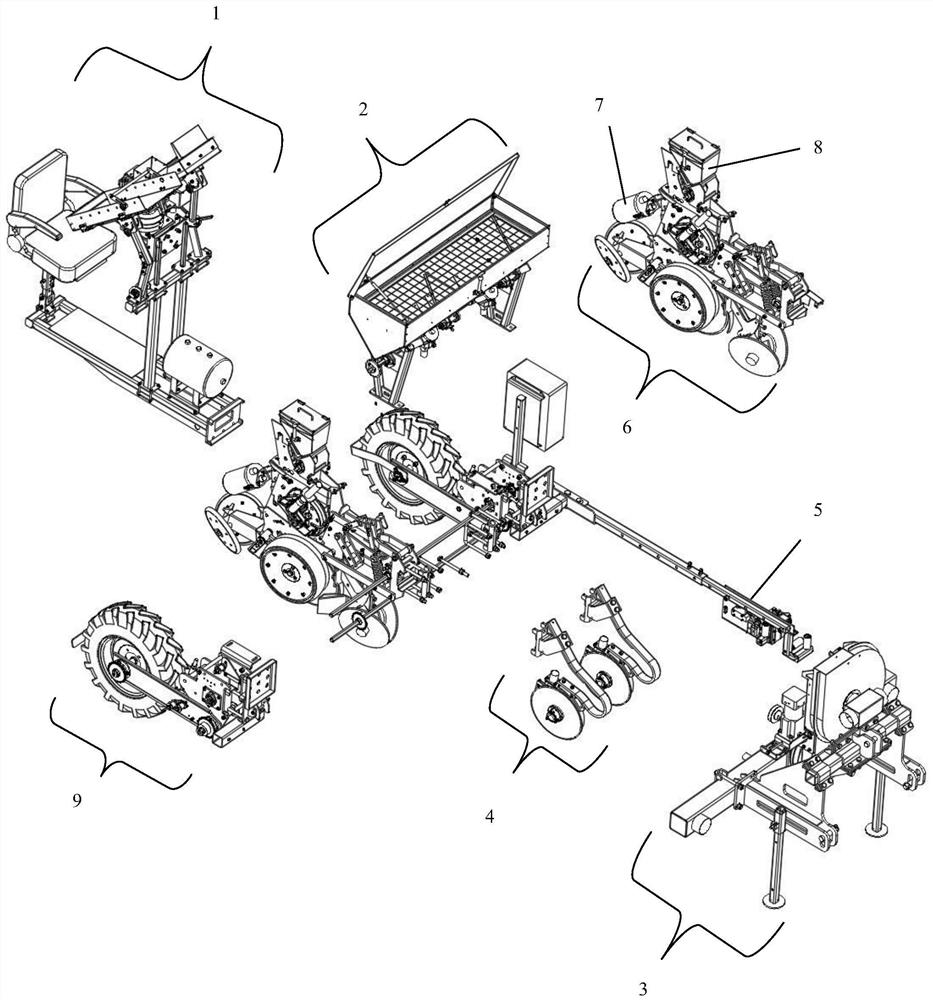

[0035] Such as Figure 1 to Figure 6 As shown, a kind of precision seeder for corn breeding experiment described in the present invention comprises main frame, operation platform (1), fertilization device (2), pneumatic device (3), fertilization ditch opener (4), boundary Detection device (5), seeding unit (6), seed cleaning box (7), pesticide application device (8) and ground wheel transmission device (9); the front end of the main frame is provided with a three-point suspension mechanism, and the pneumatic device (3) is connected to The front end of the main frame, the main frame behind the pneumatic device (3) is connected with a fertilization device (2), and the rear of the fertilization device (2) is connected with an operation platform (1), and the main frame is located at the fertilization device (2) and the operation platform (1). ) are symmetrically connected to two sowing units (6), the spraying device (8) is connected to the top of the sowing unit (6), and the clear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com