Fluid mixing device

A fluid mixing and melt mixing technology, applied in fluid mixers, mixers, transportation and packaging, etc., can solve the problems of a large proportion of stirring dead zone, the area cannot be mixed evenly, and the mixture is difficult to turn over and mix. Eliminate the dead zone of mixing, enhance the degree of confusion, and improve the effect of mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The mixed material used in this embodiment takes melt 9 as an example.

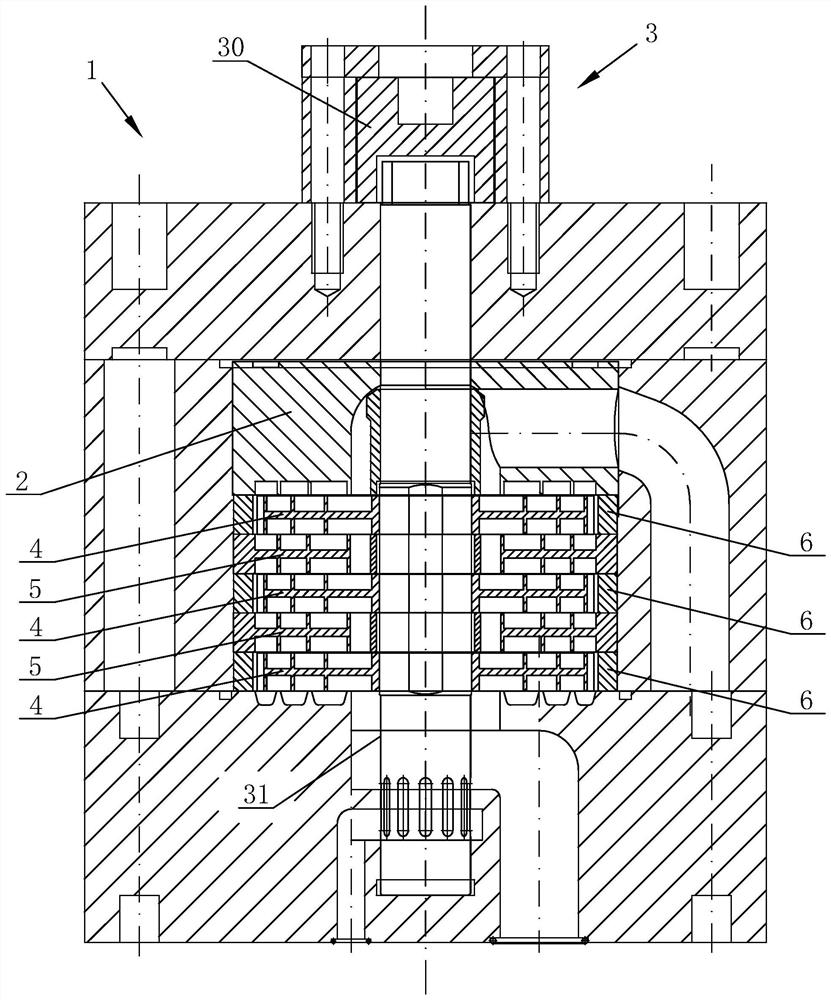

[0041] Such as figure 1 The fluid mixing device shown includes a mixing container 1, a feeding cover 2, a mixing mechanism and a driving mechanism 3 for guiding the mixing of the melt 9, and the melt 9 containing various components enters the mixing container 1 from the feeding cover 2 The homogenization process is carried out by the mixing mechanism.

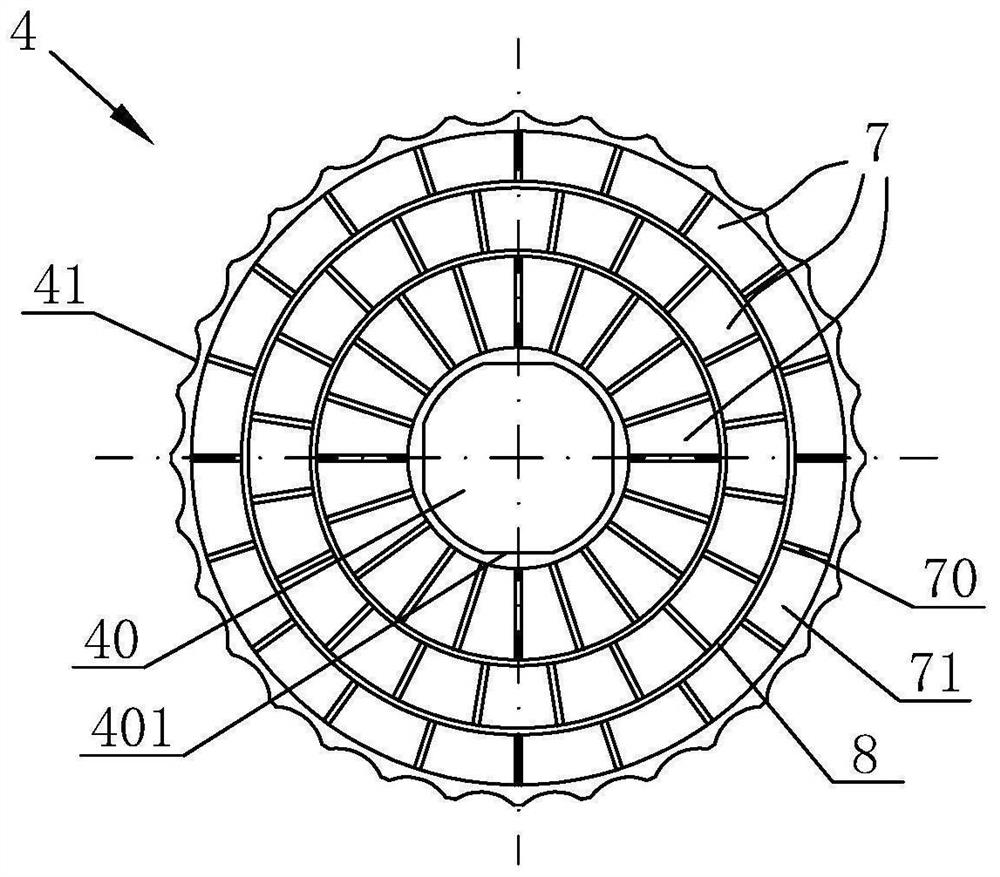

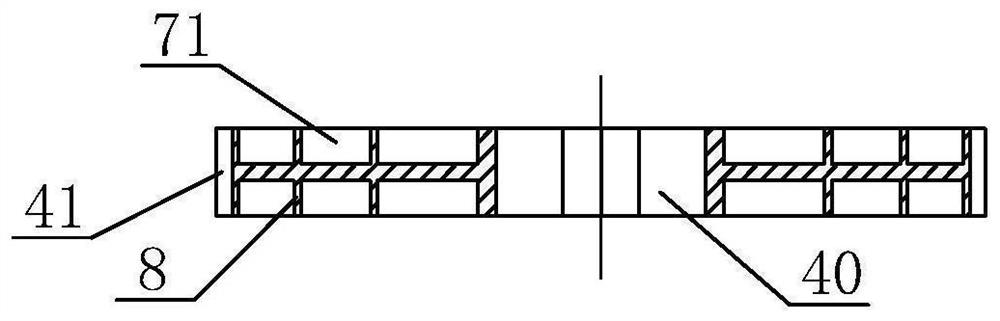

[0042] The mixing mechanism includes three first material guide discs 4, two second material guide discs 5 and three annular baffles 6, the first material guide discs 4 and the second material guide discs 5 are alternately arranged up and down, the uppermost layer and the lowermost layer Both are first material guide discs 4 , that is, two second material guide discs 5 are interposed between three first material guide discs 4 , and annular baffles 6 are sheathed on the outer circumference of the first material guide discs 4 .

[0043] The driving ...

Embodiment 2

[0055] Such as Figure 18 As shown, this embodiment is based on the technical solution of Embodiment 1, and the technical points of difference between this embodiment and Embodiment 1 are:

[0056] The annular material guide groove 7 has three layers in total, wherein the material guide grid 71 of the annular material guide groove 7 in the middle is provided with an X-shaped deflector 10, and the four ends of the X-shaped deflector 10 are respectively arranged on the material guide. At the four corners of the lattice 71, the X-shaped deflector 10 can guide the melt 9 to flow in a path with a larger span, and the melt 9 in the A material guide lattice 71 can flow through the X-shaped deflector 10 and flow to A 1 Guide grid 71 and A 2 Material guide grid 71, the melt 9 in the B material guide grid 71 can flow through the X-shaped deflector 10 and flow to B 1 Guide grid 71 and B 2 The material guide grid 71, and the melt 9 from adjacent A and B material guide grids 71 can cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com