Visual grading method and grading production line for pear appearance quality

A grading method and quality technology, applied in the field of visual grading method and grading production line of pear appearance quality, can solve the problem of not being able to determine whether the grading conforms to the national standard, unable to meet the needs of pear appearance quality grading, and the grading device does not clearly indicate the grading standard. , to maintain long-term stable operation, reduce secondary mechanical damage, and achieve the effect of complete function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

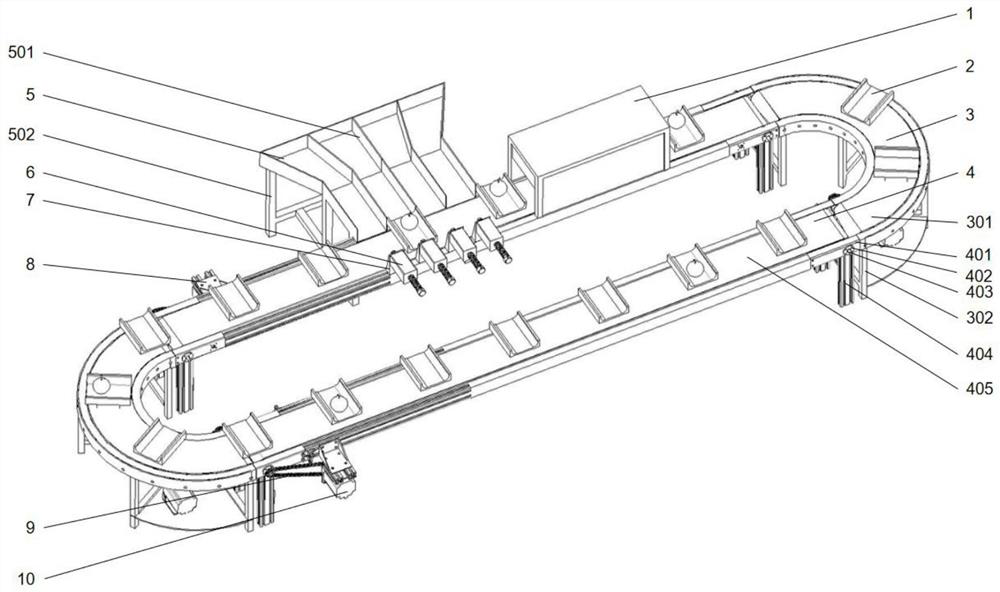

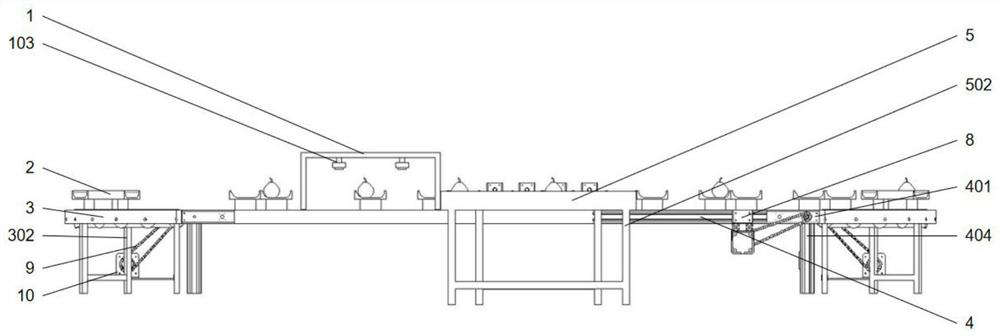

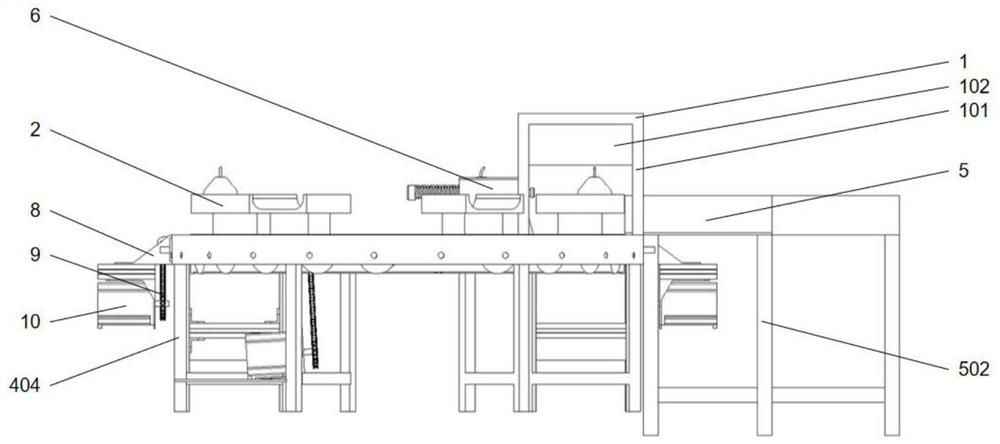

[0047] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the present application.

[0048] The present invention is used for the visual grading method of pear appearance quality, and the grading method is applicable to the national standard GB / T 10650-2008 "Fresh Pears". The steps of the grading method are:

[0049] Step 1: Obtain images of fruit pears to be graded through industrial cameras, and obtain sample pear images to form a sample pear image library. The number of samples in the sample pear image library is N, and N is an integer greater than 200;

[0050] The second step: Randomly select more than half of the images in the sample pear image library as the training set, and the rest as the test set, perform grayscale transformation on the image to obtain the grayscale image of the original image, and then use the Otsu method (OT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com