Aviation part cleaning and drying box with good cleaning effect

A technology of cleaning effect and drying box, applied in the field of aviation parts, can solve the problems of inability to carry different parts, poor cleaning effect, easy pollution of the environment by waste liquid, etc., to achieve easy operation, ensure cleanliness, Ease of cleaning and rinsing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

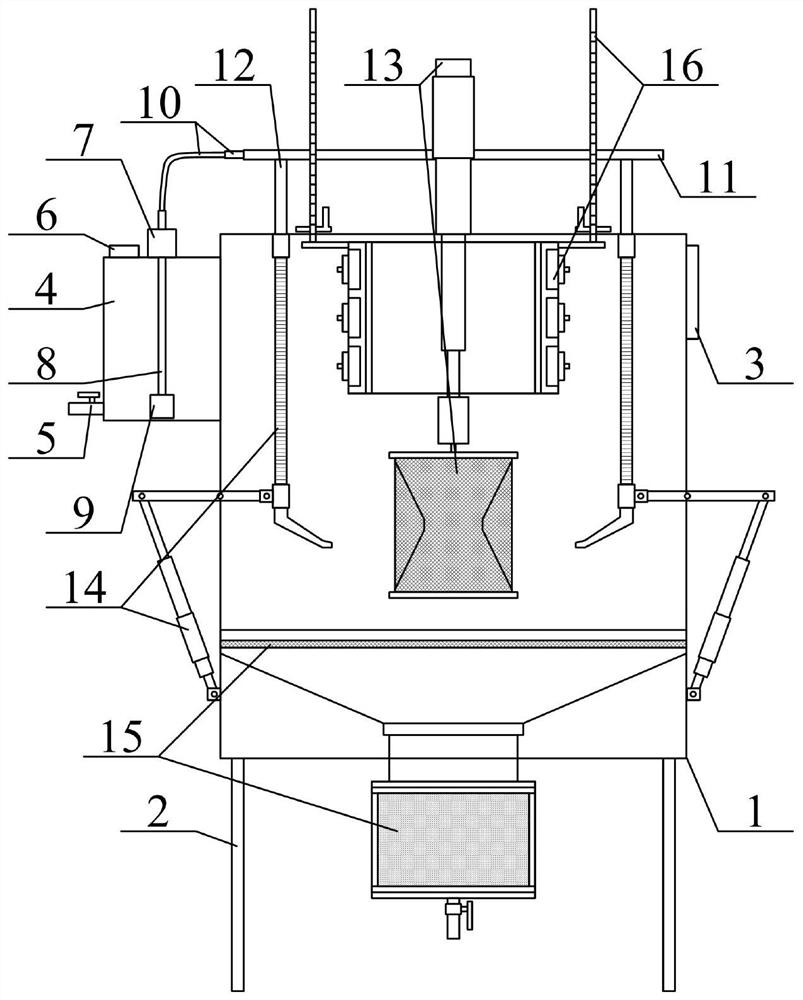

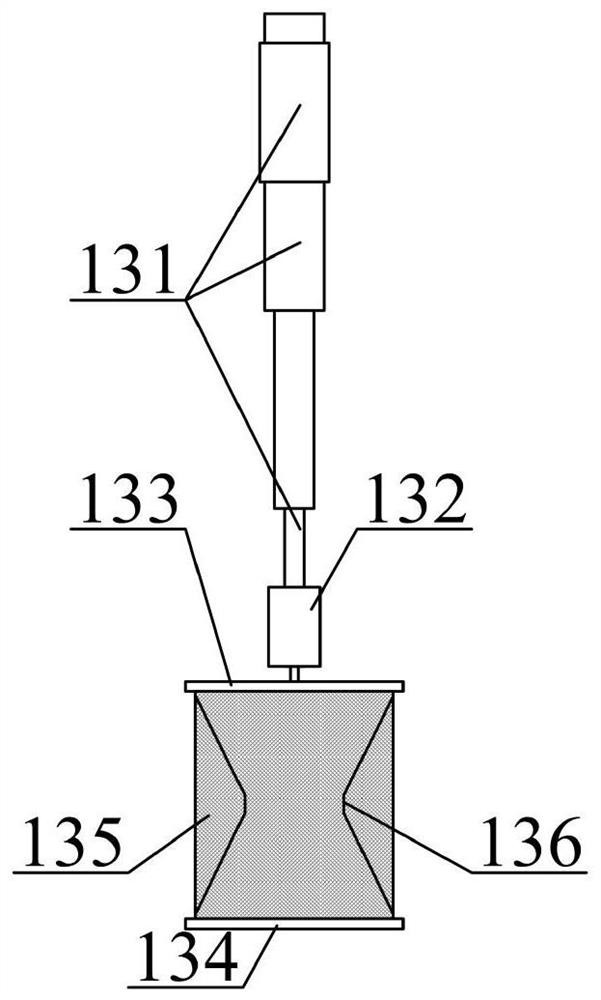

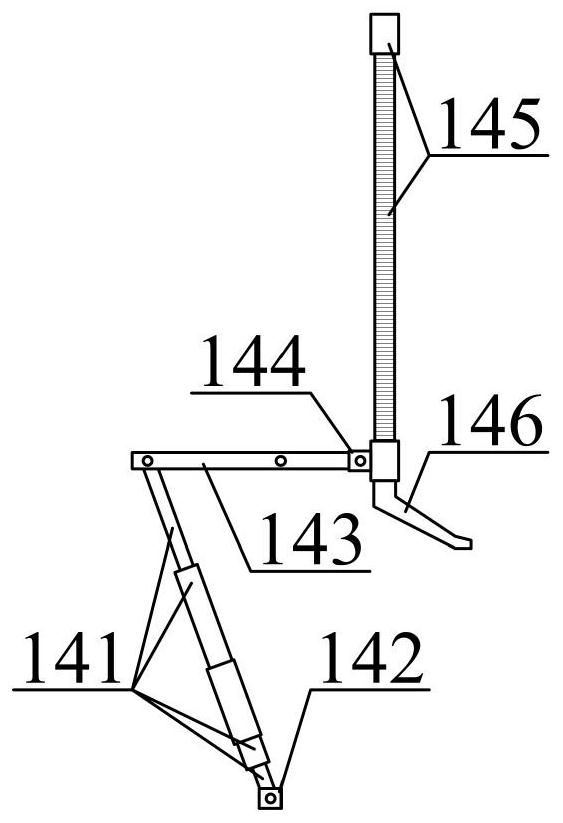

[0037] The present invention will be specifically described in conjunction with the accompanying drawings. figure 1 Attach figure 2As shown, an air parts having a good cleaning effect include cleaning the drying box 1, the support leg 2, the control panel 3, the cleaning liquid tank 4, the sewage valve 5, the liquid cover 6, the flushing pump 7, Pipe 8, anti-miscellaneous network pocket 9, rubber bellows 10, flow row 11, guide tube 12, rotary type lifting component carrier network barrel structure 13, adjustable ripple rolling tube structure 14, waste liquid filtration Structure 15 and the lifting drying heating sheet structure 16, the cleaning drying box 1 bottom four-corner portion bolt is connected to the support leg 2; the cleaning drying box 1 is connected to the right upper bolt connection with a control panel 3; Cleaning Drying Box 1 The upper left side bolt is connected to the cleaning liquid tank 4; the cleaning liquid tank 4 is threaded at the lower left exit of the clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com