Intelligent forging equipment with adjustable function and intelligent forging method

An adjustable and functional technology, applied in the direction of metal processing equipment, manufacturing tools, forging presses, etc., can solve the problems that the clamp distance cannot be changed, the metal blank cannot be forged, and the work requirements cannot be met, so as to improve safety performance, The effect of reducing maintenance costs and avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

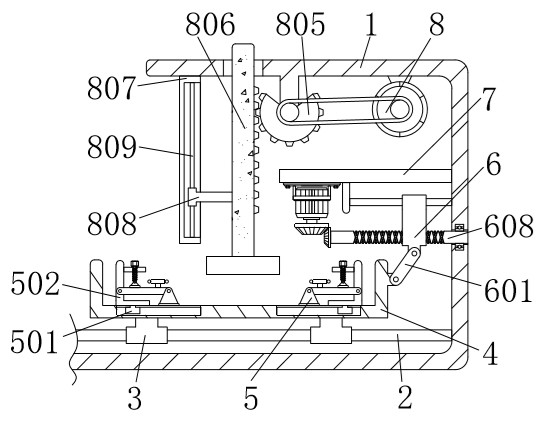

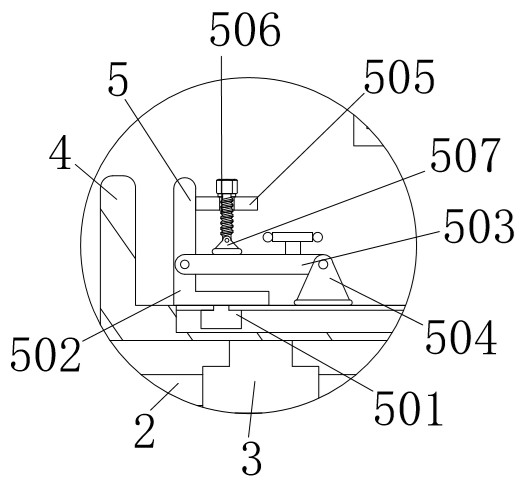

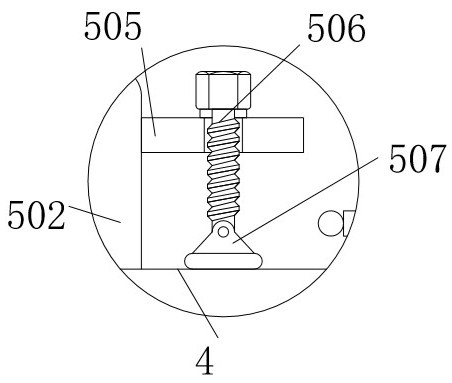

[0032] An intelligent forging equipment with adjustable function, comprising a first casing 1, a sliding rod 2, a first sliding block 3 and a second casing 4, a sliding rod 2 is fixedly connected to the bottom of the right side of the inner wall of the first casing 1, and the sliding rod The outer wall of 2 is slidably connected with two sliders 3. The two sliders 3 can slide left and right on the sliding rod 2. The top of the two sliders 3 is fixed with a second shell 4, and the inner wall of the second shell 4 has two left and right sides. Both sides are provided with fixing devices 5. The fixing device 5 includes a second sliding block 501, a curved plate 502, a horizontal plate 503, a first trapezoidal block 504, a short plate 505, a first bolt 506 and a second trapezoidal block 507. The outer wall of the block 501 is slidably engaged with the left groove at the bottom of the inner wall of the second housing 4, the second sliding block 501 can move left and right in the gro...

Embodiment 2

[0034] As an optional case, see figure 1 and 4, an intelligent forging equipment with adjustable function, the inner right side of the first casing 1 is provided with a mobile device 6, and the mobile device 6 includes a sloping plate 601, a thick plate 602, a thin rod 603, a vertical plate 604, a first motor 605, a first A bevel gear 606, a second bevel gear 607 and a reciprocating screw 608, the left side of the swash plate 601 is rotatably connected to the top of the right side of the second housing 4 through a pin shaft, the swash plate 601 can be rotated through the pin shaft, and the swash plate The right side of 601 is rotatably connected to the bottom of the thick plate 602 through a pin, the upper inner wall of the thick plate 602 is slidably connected to the outer wall of the thin rod 603, the thick plate 602 can move on the outer wall of the thin rod 603, and the right end of the thin rod 603 is The right side of the inner wall of the first housing 1 is fixedly con...

Embodiment 3

[0037] As an optional case, see figure 1 , 5 And 6, intelligent forging equipment with adjustable function, a forging device 8 is provided above the inner wall of the first housing 1, and the forging device 8 includes a second motor 801, a first sheave 802, a belt 803, a second sheave 804, gears 805, rack 806, square plate 807, long plate 808, long rod 809 and pressing block 810, the top of the second motor 801 is fixedly connected to the top right side of the inner wall of the first housing 1 through a bracket, and the model of the second motor 801 is ECMA-E11320RS, the output end of the second motor 801 is fixed with the first sheave 802, the second motor 801 can drive the first sheave 802 to rotate, and the outer wall of the first sheave 802 passes through the belt 803 and the second sheave 804. The outer wall is connected in rotation. When the first sheave 802 rotates, it can drive the second sheave 804 to rotate through the belt 803. The rear end surface of the second sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com