Iron mold sand-lined casting process with core making function and sand-lined mold

A sand-covered iron mold and iron mold technology, which is applied in the manufacture of tools, casting molding equipment, casting molds, etc., can solve the problems of cumbersome procedures and low production efficiency, achieve simplified procedures, low energy consumption costs, and improve overall work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

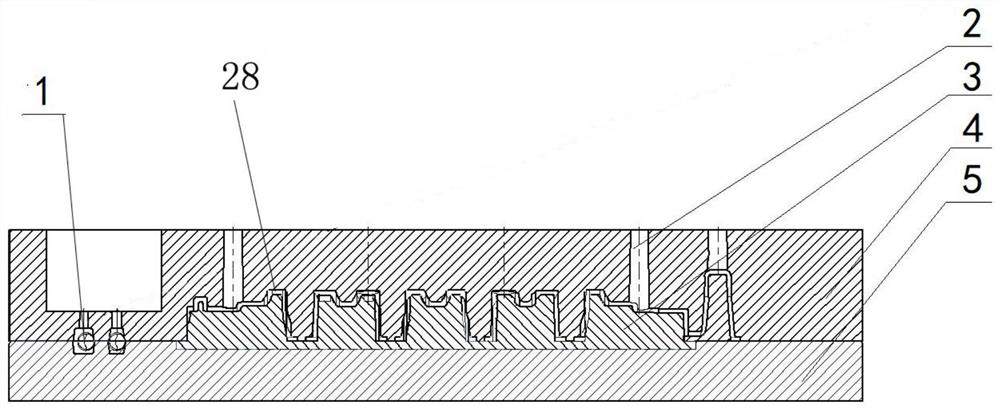

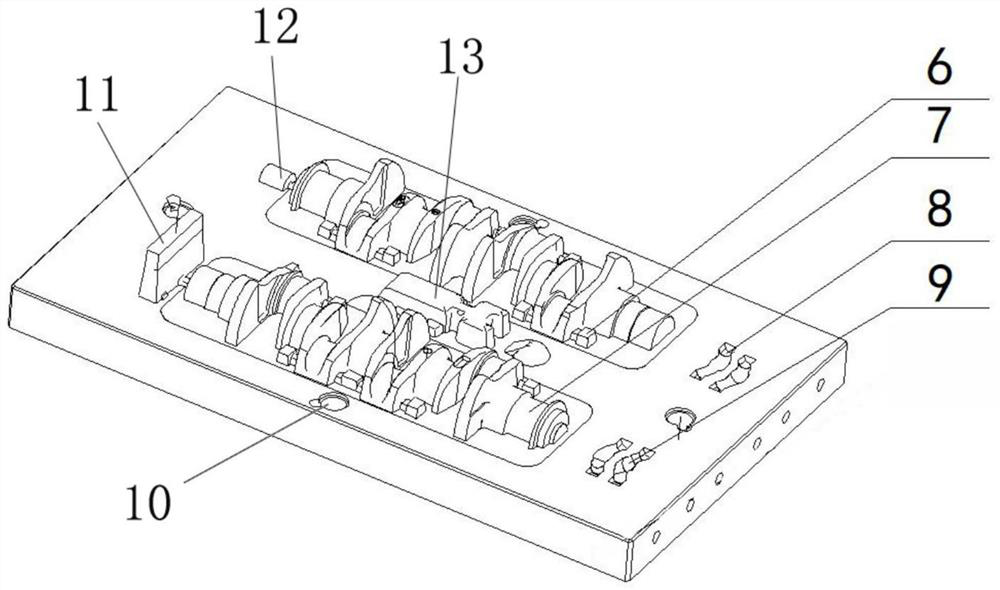

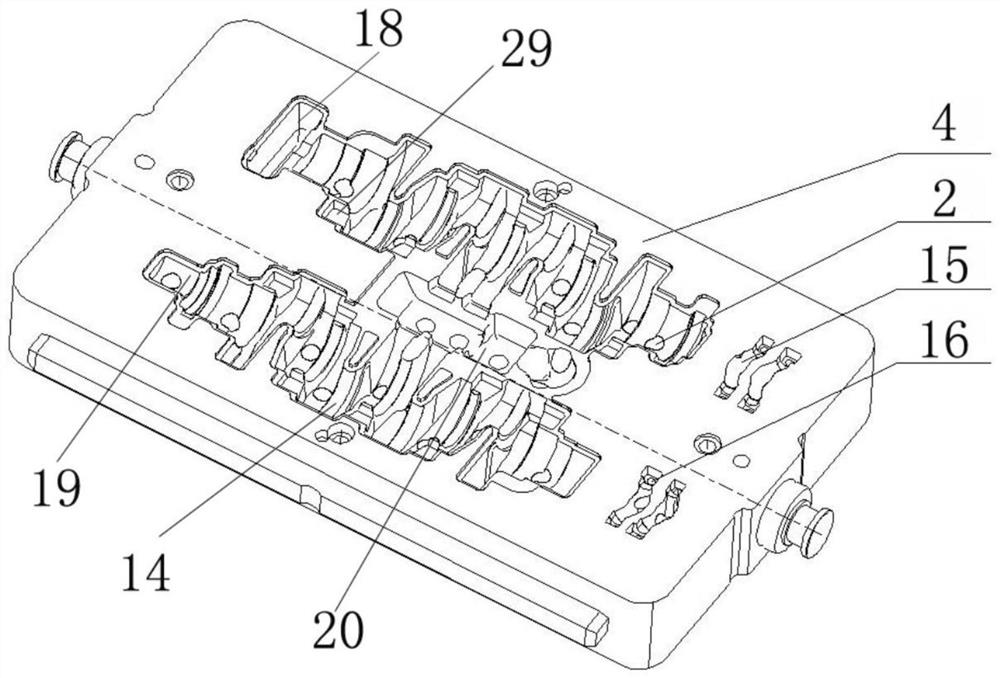

[0037] Example 1: SN1000 crankshaft

[0038] The weight of the parts is 40Kg, and there are two pieces in a box. Each piece needs to be installed with 4 oil channel sand cores at the position of the connecting rod neck. The sand cores are taken out 4 in the upper shape mold and the upper iron mold, and 4 are taken out in the lower shape mold and the lower iron mold. There is no need to use a core box, and it is directly made from the shape mold and iron mold. The sand core is ejected on the transport trolley, and after the perforation on the cavity of the residual iron sand core is manually removed, glue is glued to the position of the core head, and the shape mold core is completed. It saves a core shooting operator and a core box investment, and the effect is good.

Embodiment 2

[0039] Embodiment 2: Production of EA188 flywheel

[0040] The weight of the parts is 90Kg, one piece per box. The center hole of the flywheel is large in the middle and small at the two ends, so it cannot be lifted out by the lifting core scheme, and only sand cores can be installed. In order to avoid the input of core boxes, a combination of shape molds and iron molds is also used to obtain sand cores while producing shape molds.

[0041] The casting method of the present invention also produces parts such as the differential case of the truck, the crankshaft of the hollow oil passage, and the crankshaft of the six-cylinder engine, all of which realize the coreless box scheme, reduce the cost of tooling and molds, and reduce labor, and have achieved many advantages. significant benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com