Dental implant processing device and processing method

A processing device and a technology for dental implants, applied in the field of denture processing, can solve the problems of poor hand-length adaptation of staff, affecting work quality and efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

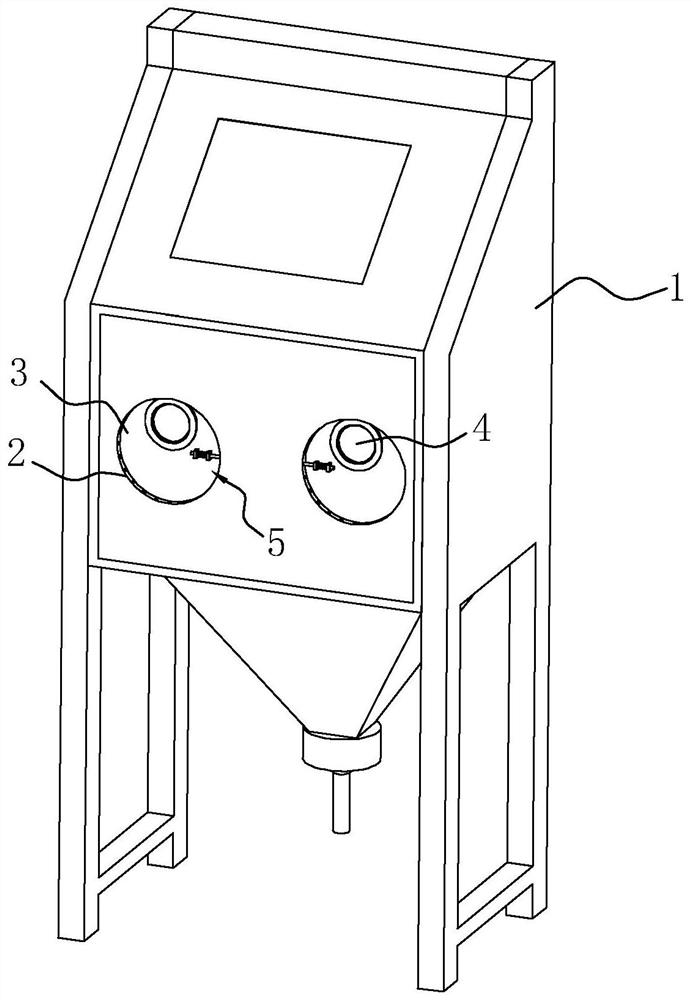

[0038] The embodiment of the present application discloses a dental implant processing device. refer to figure 1 , The dental implant processing device includes a body 1, and a sandblasting pipe (not shown in the figure) is connected to the body 1, and the workpiece to be sandblasted is put into the body 1 for sandblasting.

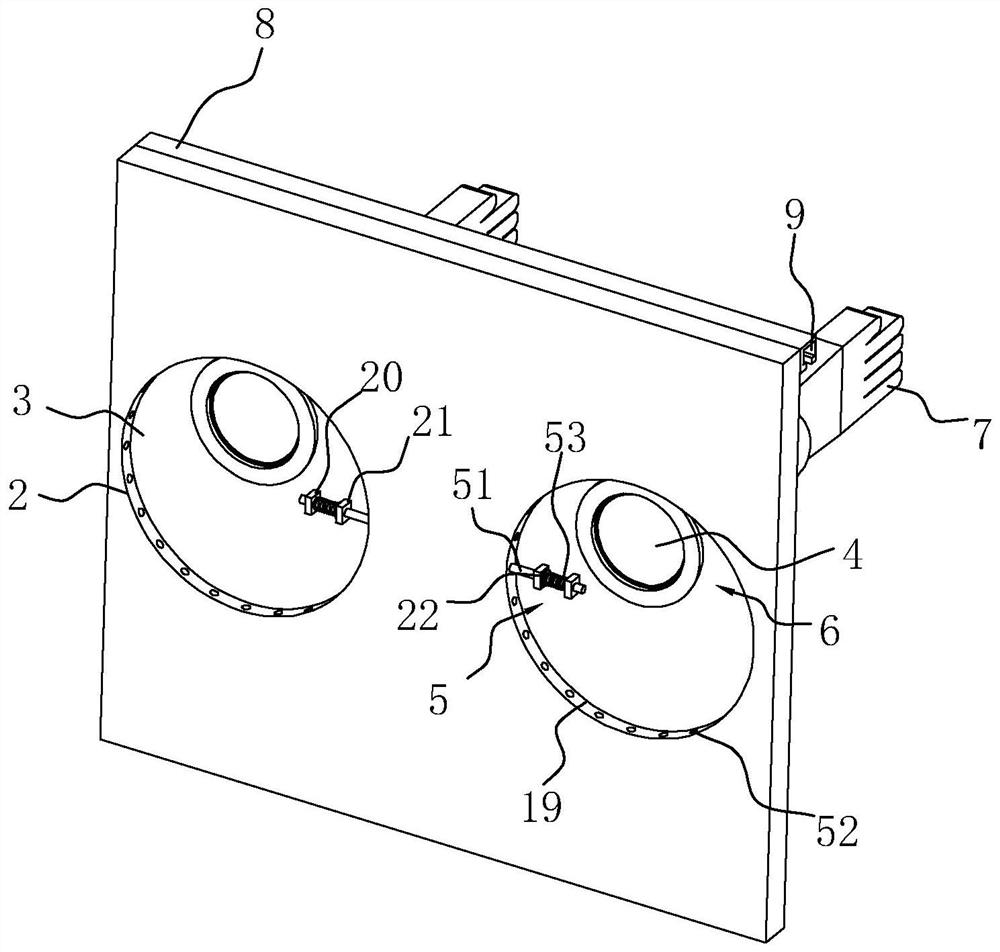

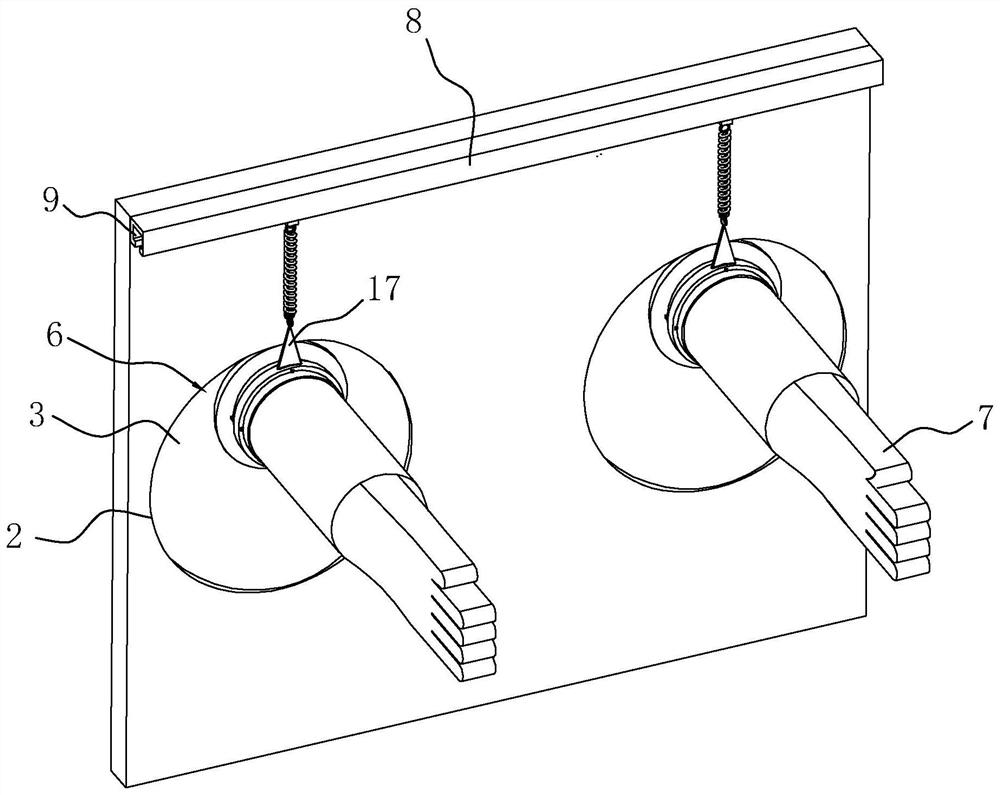

[0039] refer to figure 1 and figure 2The side wall of the body 1 is provided with two round holes 2, and the two round holes 2 are connected with a rotating plate 3. The rotating plate 3 and the round hole 2 are coaxially arranged, and the rotating plate 3 is provided with two hand holes. 4, and the position of the hand hole 4 is rotatably connected with a swivel seat 6, and a glove 7 is detachably installed on the swivel seat 6. Limiting groove 19 is offered on the inner wall of circular hole 2, and limiting groove 19 is coaxial with circular hole 2, and the edge of rotating plate 3 is positioned in limiting groove 19, thereby realizes the rotation o...

Embodiment 2

[0048] This embodiment discloses a dental implant processing method, comprising the following steps:

[0049] (1) Choose titanium alloy or pure titanium raw materials, and make the raw materials into a rod-shaped structure. You can also buy titanium raw materials that are already rod-shaped, and use CNC machine tools to mill and process them to make implants. The cutting length of the implants is 15-30mm , and process a certain number of threaded grooves on the implant through a tapping machine for installing the implant abutment, and then process a convex thread on the outer wall of the implant through an outer threading machine for use with The gums are in contact with each other, and then use a polishing machine and other devices to polish the surface of the obtained product, and then use distilled water to clean and dry;

[0050] (2) Pickling the implant obtained above, the acid solution is a mixture of hydrochloric acid and sulfuric acid, and then washing with distilled w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com