Self-adaptive anti-shearing large-deformation anchor rod

A shear-resistant, large-deformation technology, applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problem of high elastic properties of materials, shear damage, and unchanged shear force of bolts State and other issues, to achieve the effect of improving shear resistance and long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

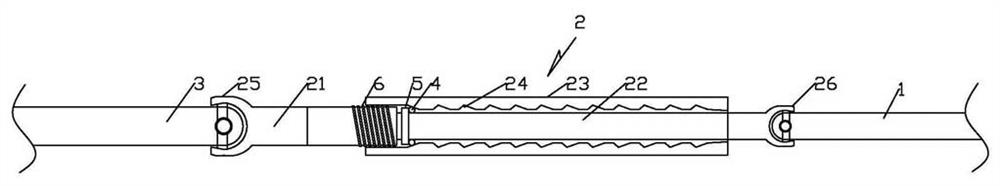

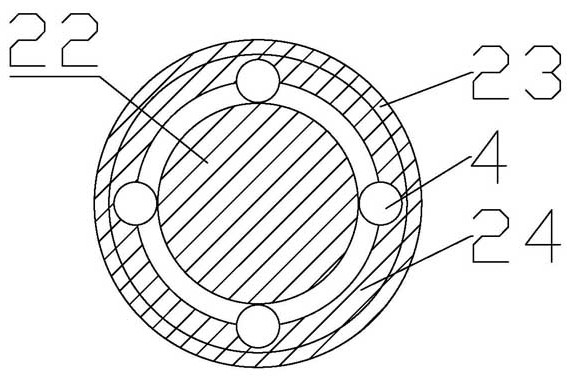

[0020] The self-adaptive anti-shearing large deformation bolt of the present invention comprises a free section 1 , a large shearing deformation section 2 and an anchoring section 3 . The large shear deformation section 2 is composed of a connecting rod 21 at the anchoring end, a connecting rod 22 at the free end, and a casing 23. The casing 23 is a steel casing, the inner wall of one end is threaded, and the other end is provided with locking teeth. 24. The locking tooth 24 is in the shape of slow front and steep back (with the free section as the front), and the angle and thickness of the locking tooth can be changed, so that constant resistance of different sizes and different energy absorption paths can be realized. Described anchoring end connecting rod 21, its rear part is provided with fork joint 25, front part is provided with screw thread 6, and the front end of anchoring end connecting rod 21 is connected with sleeve pipe 23 thread end, and the rear end of anchoring e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com