Tin-bismuth series lead-free solder and preparation method thereof

A lead-free solder, tin-bismuth technology, applied in welding equipment, welding/cutting media/materials, manufacturing tools, etc., can solve problems such as thermal fatigue resistance, poor ductility, limited promotion and application, and insufficient welding reliability, and achieve Good wettability, improved shear resistance, good wetting and spreadability, and the effect of shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

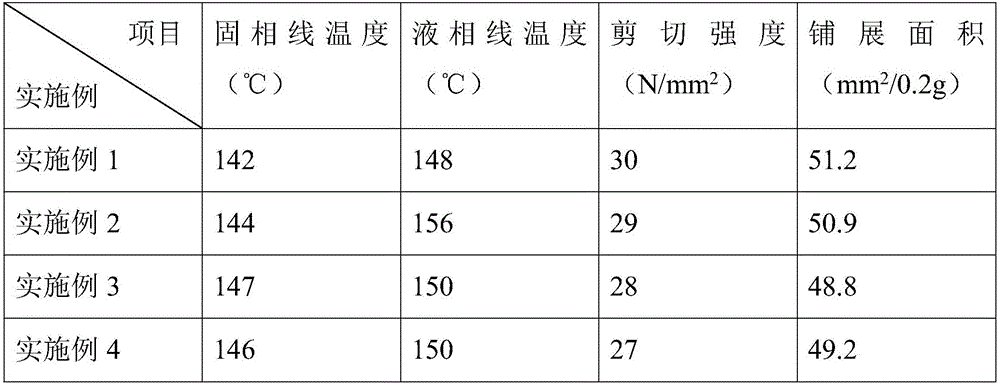

Examples

Embodiment 1

[0026] A tin-bismuth lead-free solder, calculated by weight percentage, is made of the following raw materials:

[0027] Bismuth 26%, CeO 2 Nano particles 2.4%, silver 0.3% and P 0.04%, the balance is tin. CeO 2 The particle size of the nanoparticles is 50 nm.

[0028] Preparation:

[0029] 1) Weigh bismuth powder, silver powder, P, CeO according to the ratio 2 Nanoparticles and tin powder, and mix them into initial powder;

[0030] 2) Add appropriate amount of ether and stearic acid into the ball mill jar, then add the initial powder into it, then install the ball mill jar, then evacuate the ball mill jar and feed inert gas into it, at a speed of 300r / min Under the condition of ball milling for 120h;

[0031] 3) Take out the ball-milled alloy powder and dry it in the air to fully volatilize the ether and stearic acid to obtain the tin-bismuth-based lead-free solder.

Embodiment 2

[0033] A tin-bismuth lead-free solder, calculated by weight percentage, is made of the following raw materials:

[0034] Bismuth 27%, CeO 2 Nanoparticles 2.6%, Silver 0.4% and Ge 0.03%, the balance being tin. CeO 2 The particle size of the nanoparticles is 10 nm.

[0035] Preparation:

[0036] 1) Weigh bismuth powder, silver powder, Ge, CeO according to the ratio 2 Nanoparticles and tin powder, and mix them into initial powder;

[0037] 2) Add an appropriate amount of ether and stearic acid into the ball mill jar, then add the initial powder into it, then install the ball mill jar, then evacuate the ball mill jar and pass inert gas into it, at a speed of 400r / min Under the condition of ball milling for 100h;

[0038] 3) Take out the ball-milled alloy powder and dry it in the air to fully volatilize the ether and stearic acid to obtain the tin-bismuth-based lead-free solder.

Embodiment 3

[0040] A tin-bismuth lead-free solder, calculated by weight percentage, is made of the following raw materials:

[0041] Bismuth 24%, CeO 2 Nano particles 3.0%, silver 0.6% and Ge 0.06%, the balance is tin. CeO 2 The particle size of the nanoparticles is 10 nm.

[0042] The preparation method of the low melting point lead-free solder in this embodiment is the same as the method described in embodiment 2, the only difference is that the weight percentages of the components of the lead-free solder alloy are weighed according to the proportions in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com