Ash content self-cleaning wall-flow type spherical DPF

A particle trap and wall-flow technology, which is applied in the direction of machines/engines, exhaust treatment, mechanical equipment, etc., can solve problems such as ash clogging, and achieve the effects of improving service life, simple control, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

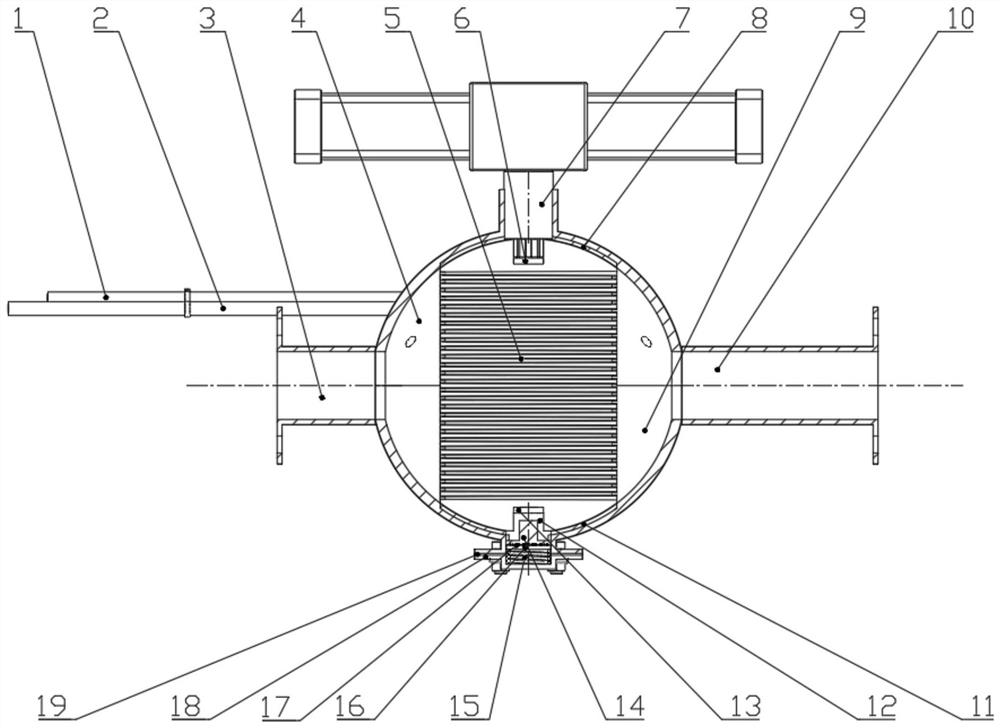

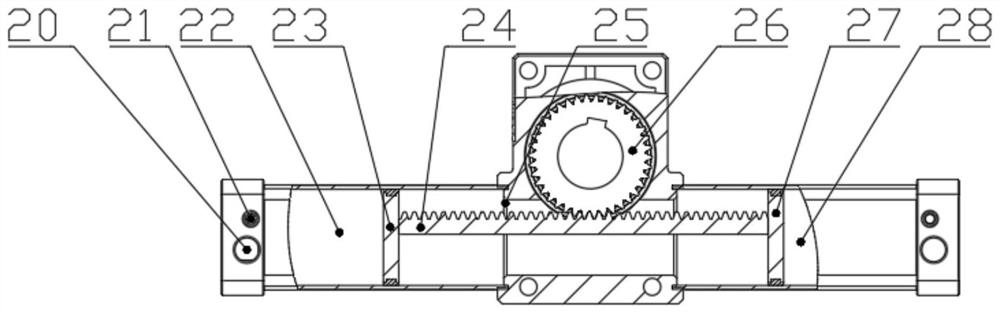

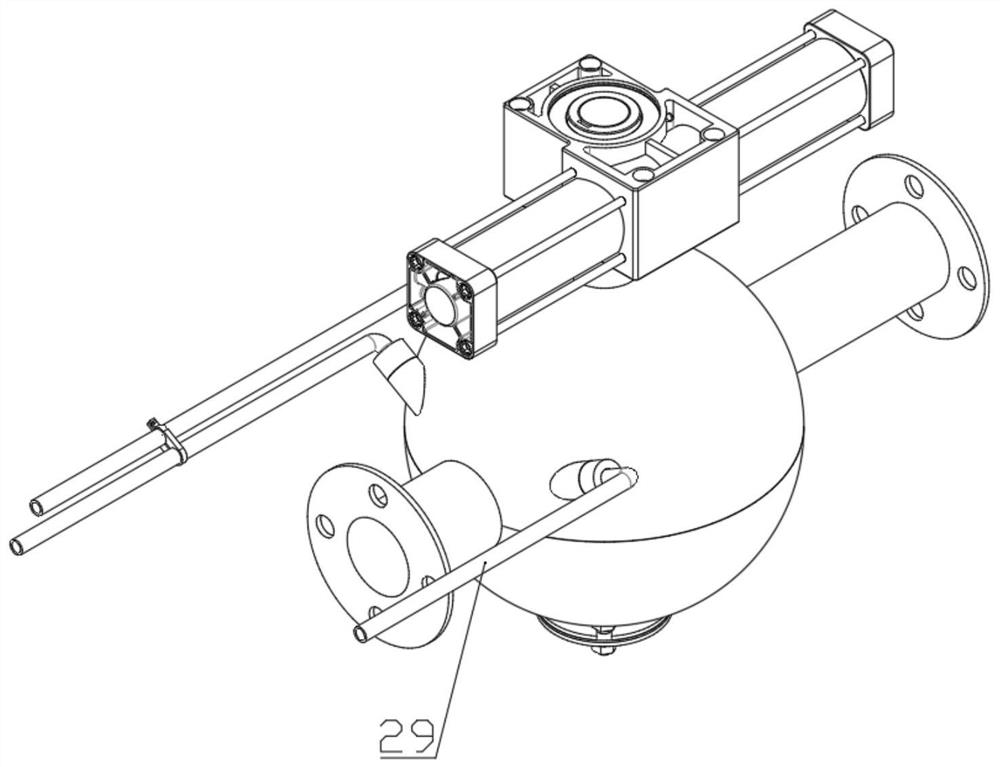

[0058] According to the attached Figure 1-6 The technical solution of the present invention is described in detail.

[0059] figure 1 As shown, this embodiment provides an ash self-cleaning wall-flow spherical particle trap, which includes a wall-flow spherical DPF, a carrier steering drive mechanism, a first pressure sensor 1, a second pressure sensor 2, a drum-shaped Filter carrier 5, temperature sensor.

[0060] The wall-flow spherical DPF is used to filter the particulate matter emitted by the engine, and can self-clean the ash after multiple regenerations.

[0061] The carrier turning drive mechanism is used to rotate the drum-shaped filter carrier 5 back and forth by 180°.

[0062] The first pressure sensor 1 and the second pressure sensor 2 are used to detect the pressure before and after the DPF.

[0063] The temperature sensor is used to detect the temperature of upstream engine gas entering the DPF.

[0064] The wall-flow spherical DPF has a circular platform a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com